INTRODUCTION

A general tendency to reduce the salt content in consumer diet, in agreement with the Global Strategy on Diet, Physical Activity and Health, has led producers to reduce the salt content in dry-cured hams [Desmond, 2006; Waxman, 2004]. However, this technological intervention resulted in a modified texture of the product; salt reduction during processing led to excessive activity of proteolytic enzymes, resulting in a soft, pasty texture, being the two main texture problems [Contreras et al., 2020, 2021; Ruiz-Ramírez et al., 2006; Virgili et al., 1995]. Currently, the slightly tough texture, typical for Kraški pršut – Slovenian dry-cured ham, has been replaced by a soft, very soft, and even pasty texture, which represents a significant challenge for producers. The frequency and intensity of this shift in texture during industrial processing remain unknown, as the phenomenon of pasty texture of dry-cured ham is very complex [Morales et al., 2007b]. Several process factors that affect the texture of dry-cured ham have been studied; for example, one of the most important is salting because when the salt content decreases, fibre swelling decreases, resulting in poor texture [Desmond, 2006; Gou et al., 2008]. The production of high-quality ham requires the consideration, monitoring, and control of a variety of processing factors (ripening time and temperature, salting, mass loss, water activity and pH values) related to textural properties (e.g., hardness, pastiness, adhesiveness) and proteolytic activity [Pérez-Santaescolástica et al., 2018].

Information on the relationship between the extent of proteolysis and the texture of ham is somewhat contradictory. Hence, in this study, technological parameters (pork thighs supplier, thigh mass, salt content, and mass loss after production) were investigated in relation to quantitative parameters of proteolysis, including non-protein nitrogen (NPN) content and proteolysis index (PI), and texture parameters of the final product. Therefore, the initial aims were to determine the sensory acceptable texture of Kraški pršut, identify a deficient texture and link it to instrumental measurements of texture, degree of proteolysis, mass classes of pork thighs, suppliers and mass losses during production. Based on the assessments of the panel of sensory experts, we tried to find values for optimal texture parameters, as well as values for undesirable texture (too soft or too firm). In addition, the influence of mass losses during the production and the content of NPN on the texture parameters and sensory attributes of dry-cured ham was studied. All findings are expected to contribute to the improvement of the final product.

MATERIALS AND METHODS

Material and experimental design

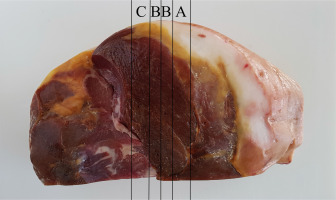

Slovenian dry-cured ham – Kraški pršut (KP) – with protected geographical indication was used in the study. A total of 32 samples of Kraški pršut (410±33 days after salting) were included in the experiment. The manufacturer’s data, ham mass before salting and at the end of the production process, and mass loss at the end of ripening were determined for the samples. The KP samples were divided according to mass of pork thighs at salting into two classes of 16 pieces each: light (L; 10.5–10.7 kg) and heavy (H; 11.7–12.1 kg), and within each mass class according to two suppliers of pork thighs (A and B); class L: 4 pieces from supplier A and 12 pieces from supplier B, class H: 8 pieces from supplier A and 8 pieces from supplier B. All KP samples were cut in half. The halves were weighed and sliced for various analyses (Figure 1). The pH and contents of water and intramuscular fat, NaCl, protein, and non-protein nitrogen (NPN) were measured on slice A; instrumental texture profile analysis (TPA) was carried out on slice B; and sensory analysis of the textural attributes of the samples was performed on slice C.

Physicochemical properties analysis

The superficial connective and adipose tissue were removed from the dry-cured ham slices. Then, approximately 100 g of a representative sample was homogenized for 20 s using a Grindomix homogenizer (GM 200; Retsch, Haan, Germany) at 5,000–6,000 rpm. After determination of pH and moisture content, the reminding homogenized samples were vacuum packed and stored at −20°C until further chemical analyses.

The pH was measured in an aqueous extract of homogenized ham. The extract was obtained by mixing 5 g of homogenate with 50 mL of distilled water, followed by filtration of the suspension after 30 min. The pH of the filtrate was measured using a combined glass-gel spear electrode (Type 03, Testo Pty Ltd, Croydon South, Victoria, Australia) with the accuracy of 0.01 units. Two buffers (pH 4.00 and pH 7.00) were used for the pH- -meter calibration.

Moisture content was determined as the mass loss of 5 g of the homogenized sample dried to constant mass at 105°C by the official method 950.46 of AOAC International for moisture in meat [AOAC, 1997].

Total fat was determined by weight after Soxhlet extraction (SoxhletTM 2050, Foss, Hillerød, Denmark) using petroleum ether as a solvent.

The Kjeldahl method was used to determine the total nitrogen content. The assay was carried out in accordance with the method 928.08 of AOAC International – Nitrogen in meat [AOAC, 1997]. The total nitrogen content was multiplied by 6.25 to calculate the protein content.

Non-protein nitrogen (NPN) content was determined by precipitating proteins with trichloroacetic acid and then determining the nitrogen content in the extract by the Kjeldahl method [AOAC, 1997]. Non-protein nitrogen was expressed as a percentage of non-protein nitrogen relative to total nitrogen. The proteolysis index (PI) was calculated as the ratio of NPN to total nitrogen (expressed as a percentage) [Careri et al., 1993; Virgili & Schivazappa, 2002].

The salt content (NaCl) was measured using a sodium ionselective electrode (DX223; Sodium Analyser AP214, Mettler Toledo GmbH, Zurich, Switzerland).

All parameters were determined in parallel and given as arithmetic means. The contents of moisture, total fat, protein, NPN and NaCl were expressed as a percentage of the initial mass.

Instrumental texture profile analysis

For instrumental measurement of textural properties, two 15 mm thick slices were taken from each KP sample. Using a scalpel, 12 squares measuring 20×20×15 mm were carefully cut from the muscles: – semimembranosus (SM) and biceps femoris (BF) (6 pieces for each muscle), covered with plastic wrap to prevent drying, and conditioned at a temperature of 4°C for 2 h. TPA was performed as described previously by Morales et al. [2007a] on three samples using the XT Plus texture analyser (Stable Micro Systems Ltd., Surrey, UK) for each muscle. The specimens were compressed twice to 50% vertical to the muscle fibres (with an interval of 5 s between these compression cycles) and at a crosshead speed of 5 mm/s. The force-time curves were recorded, and the following parameters were calculated: hardness (expressed as maximum force of the first compression), adhesiveness (expressed as the negative work between the two cycles), springiness (expressed as a ratio or percentage of the original downstroke compression), chewiness (expresses as the product of hardness, cohesiveness and springiness), and resilience (expressed by dividing the upstroke energy of the first compression by the downstroke energy of the first compression).

Sensory analysis

A panel of six qualified and experienced experts in the field of meat products was appointed to evaluate the sensory characteristics of dry-cured ham. The panel has been trained [ISO 8586:2014-05] and has participated in the sensory profiling of Kraški pršut on the Slovenian market for at least 10 years. The preparation of the descriptors was carried out during the last three sessions. The sensory evaluation of KP samples was carried out under defined, precisely prescribed, controlled and reproducible conditions which included arrangement of laboratory, samples, accessories and organization of assessment [ISO 8589:2007; ISO 8586:2012]. Assessment of the coded samples took place in a standard sensory laboratory. For each sample, two thin slices (0.5 mm) at room temperature (20°C) were randomly served to the panellists on a white plate. To neutralise the taste, the panel used the middle dough of white bread and water. The panel evaluated the samples separately in two sessions (days) with 16 samples each. The analytical descriptive test [Gašperlin et al., 2012] was performed by scoring the sensory attributes on a structured scale from 1 to 7 points, where a value of 1 means that the attribute is not expressed, and a value of 7 means a strongly expressed attribute. The panel could also use half values. The sensory profile of the KP samples was evaluated using seven descriptors divided into four blocks related to (I) visual attributes on the surface of the slice, namely marbling; (II) texture attributes, namely overall hardness, pastiness, and solubility; (III) olfactory attributes, namely odour intensity; and (IV) aroma attributes, namely aroma intensity and saltiness. The definitions of the descriptors are listed in Table 1.

Table 1

Definitions of descriptors used in the sensory evaluation of dry-cured hams.

Statistical analysis

Data were analysed using the SPSS statistical program (version 23.0, SPSS Inc., Chicago, IL, USA). The normality of the distribution and the homogeneity of variance were tested using the ShapiroWilk test (α=0.05) and the Levene test. The experiment aimed to evaluate the physicochemical, TPA parameters and sensory attributes of KP samples was performed with a 2×2×8 mixed factorial experimental design (2 types of mass classes (H and L), 2 types of thighs suppliers (A and B), and 8 production replicates). As the interaction mass class × thigh supplier was not significant (p>0.05), it was removed from model 1. A statistical model 2 was used to analyse the differences between the KP samples, which were classified into three ranks according to the calculated median value (SPSS, Descriptive Statistics, Explore) of six ratings of mouth hardness (M) by the panellists for each KP sample (ranks: median 4.0 (optimal), median 3.5 (soft), median 3.0 (very soft)). Differences between the groups/ranks were considered significant at p≤0.05. Pearson correlation coefficients between the parameters were calculated using the Correlate procedure of SPSS software, and the interactions between the variables were analysed using the multivariate linear descriptive analysis (LDA) method.

RESULTS AND DISCUSSION

Physicochemical parameters and sensory attributes of Kraški pršut

As shown in Table 2, there were significant effects of mass classes and thighs suppliers on some physicochemical parameters of KP samples: dry-cured ham mass, pH value, moisture and NaCl contents. The mass of KP after sampling or before slicing ranged from 7.07 kg for light to 8.08 kg for heavy hams, where the masses from supplier A were significantly higher (p≤0.001) from those of supplier B. Values of pH were between 6.01 for light samples and 6.09 for heavy samples, with higher values noted for those from supplier A (6.11). NaCl and moisture contents were both observed higher in the products from supplier B, where light KP samples had higher content of NaCl (5.30 g/100 g) and lower content of moisture (42.17 g/100 g). Mass classes had no significant effect on mass loss during the production process, higher values were determined for the KP samples from supplier B than supplier A (33.53% vs 32.86%). Mass classes and thighs suppliers had no effect on protein content and proteolysis index. In contrast, total fat content was found to be significant higher (p≤0.01) in the KP samples from supplier A (23.06 g/100 g), whereas NPN content was higher in the KP samples from supplier B (7.04 g/kg).

For comparison, data from the Slovenian Nutrition Tables – Meat and Meat Products [Golob et al., 2006] given for Kraški pršut before protected geographical indication were as follows: water content of 51.8 g/100 g (44.4–57.9 g/100 g), total protein 32.1 g/100 g (25.0–43.9 g/100 g), total fat 7.4 g/100 g (6.5–8.3 g/100 g), and salt 7.6 g/100 g (4.6–10.1 g/100 g). Žlender et al. [2013], in a study on KP, found average total mass loss due to dehydration and trimming during processing from 34.75% to 36.63%, moisture content 36.99±11.77 g/100 g, protein 29.12±4.84 g/100 g, fat 27.69±14.91 g/100 g, and NaCl 5.26±1.17 g/100 g. Andronikov et al. [2013] determined higher NPN in BF muscle (22.0–23.2%) than in SM muscle (14.1–15.2%) in KP samples. Toldrá [2006] explained these high NPN values in dried meat by the fact that proteolytic enzymes are still relatively active at water activity (aw) values at the end of the production process (0.85–0.90), although a low aw value reduces the activity of cathepsins and other muscle enzymes such as aminopeptidases. The average proteolysis index in our KP samples was lower (16.7%) than these in dry-cured Italian protected designation of origin (PDO) hams (28.6%, 24.6%, and 22.4% in Parma ham, San Daniele, and Toscano prosciutto, respectively) [Piasentier et al., 2021]. In general, KP analysed in our study contained less moisture but had a comparable content of protein and salt to other better-known European dried meats, e.g., Corsican, French (Bayonne), and Italian (Parma) prosciutto (53.3–60.8%, 26.5–32.5%, 5.3–9.2%, respectively) [Virgili & Schivazappa, 2002].

The instrumental texture parameters of the KP samples are shown in Table 2. Mass classes had a significant effect on all tested parameters, with the exception of adhesiveness. The light KP samples, regardless of thighs supplier, were significantly harder, chewier, more springy, cohesive and resilient compared to the heavy samples. The main differences in ham texture may be explained by moisture content [Monin et al., 1997; Serra et al., 2007]. The hypothesis that a lower salt content promotes proteolysis, resulting in a softer texture of the final product [Gou et al., 2008], applies only to heavy hams in the present study.

Table 2

Effects of mass classes (heavy, H and light, L) and thighs suppliers (A and B) on physicochemical and texture profile analysis (TPA) parameters, and sensory attributes of Kraški pršut hams.

[i] Results are shown as mean ± standard error; n, number of dry-cured hams; pM, significance of mass classes effect; pS, significance of thigh supplier effect; Ns, not significant (p>0.05); *, significant (p≤0.05); **, highly significant (p≤0.01); ***, very highly significant (p≤0.001); M, hardness by mouth.

Mass classes and thighs suppliers had no influence (p>0.05) on the sensory evaluated marbling of the KP samples (Table 2). Panellists estimated that the light KP samples were significantly harder (p≤0.01) than the heavy ones, which coincides with instrumental measurements. Changes in hardness during ripening of Bayonne ham were attributed by researchers to both moisture content and the extent of protein proteolysis [Monin et al., 1997]. Some researchers explain the higher hardness (by mouth) of dry hams by lower pH than is typical of normal quality [Guerrero et al., 1999]. In the present study, the differences in pH values between KP samples were too small to explain the variability in hardness (M). The panellists found no significant differences (p>0.05) in pastiness and solubility between KP samples. Surprisingly, the panellists could not detect any differences in odour intensity between the KP samples. Most likely, the differences in the intensity of this olfactory property were not sufficient enough for the panellists to detect. However, they noticed significant differences in the aroma of the KP samples, where the heavy samples were estimated with higher scores (5.42) than the light ones (5.19). The light KP samples were saltier compared to the heavy samples (5.49 vs 5.13). Saltiness was also affected by thighs suppliers, with saltier KP samples from supplier B. These results are in accordance with chemically analysed NaCl content. In general, all KP samples were too salty - estimated above the optimal value of 4.0 [Gašperlin et al., 2012]. The NaCl content and sensory evaluated saltiness of KP samples were also higher compared to some other European hams, such as Parma ham (m. biceps femoris, 4.0–5.5%) [Benedini et al., 2012; Virgili et al., 2007] and de Bayonne ham (m. semimembranosus, 4.9%; m. biceps femoris, 5.6%). The high saltiness was due to high dehydration and total mass loss (average 33.3%) and was higher than in Italian ham (di Parma, San Daniele) [Virgili et al., 2007; Virgili & Schivazappa, 2002] and similar to Spanish Seranno [Ruiz-Ramírez et al., 2006] and French de Bayonne ham [Monin et al., 1997].

Classification of Kraški pršut according to sensory evaluated texture

To evaluate the texture profile, the KP samples were classified into ranks (Table 3) according to the median values obtained for hardness in sensory evaluation. Median of hardness (M) was evaluated by six panellists and used to categorise the KP samples into three ranks: median 4.0 (optimal), median 3.5 (soft), median 3.0 (very soft). The highest proportion of KP samples was categorised into rank soft (72%), followed by rank optimal (19%) and rank very soft (9%). The KP samples with optimal texture had a significantly higher NaCl content and a lower moisture content than the KP samples with soft and very soft texture. Significant differences were also observed for all TPA parameters, with the highest values noted for the KP samples with optimal texture. We did not find any similar classification of dry-cured hams in the available literature, although the statistical technique LDA is a widely applied sensory profiling method which identifies patterns in features to distinguish between different classes [Liu et al., 2018; Marques et al., 2022].

Table 3

Physicochemical and instrumental texture profile analysis (TPA) parameters and sensory attributes of Kraški pršut hams categorised into three ranks (4.0, 3.5 and 3.0) formed according to the calculated median values for hardness evaluated by sensory panellists.

[i] Results are shown as mean ± standard error; n, number of dry-cured hams; pR, significance of rank effect; Ns, not significant (p>0.05); *, significant (p≤0.05); **, highly significant (p≤0.01); ***, very highly significant (p≤0.001); M, hardness by mouth. Values with different letters (a–c) within a parameter are significantly different (p≤0.05).

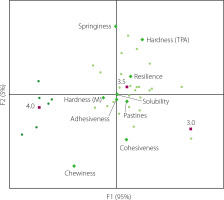

Figure 2 shows the projection of LDA parameters and data onto different ranks in the area defined by the first two functions (F1 and F2, 100% of the total variance explained). For a 100% correct distribution of KP samples into defined three ranks, only nine parameters were needed, namely, TPA parameters and sensory attributes – hardness, pastiness and solubility. The plot shows the ability of the analyses used to discriminate KP samples according to their texture. On F1, the KP samples with optimal texture (median 4.0) grouped on the left side of the plot were clearly distinguished from the KP samples with soft to very soft texture (median 3.5 and 3.0) on the right side of plot. Along F1, the KP samples with a median of 4.0 were described by the sensory descriptor hardness and the TPA parameters chewiness and springiness. In addition, the KP samples with ranks 3.5 and 3.0 (samples appeared to be more scattered) were characterised by softness (the opposite of hardness TPA) and pastiness. Compared to the samples with rank 3.5, which are located in the upper right part of the plot, the samples with rank 3.0 are located in the lower right part of the plot and are clearly related to the sensory descriptor pastiness and less related to cohesiveness, which was measured instrumentally.

Figure 2

Linear discriminant analysis of the results of sensory and instrumental texture profile analyses of the 32 Kraški pršut samples, divided into three ranks according to the median values for hardness obtained in the sensory analysis.

From the manufacturer’s point of view, it is also important from which mass class the undesirable textures of KP samples were produced, such as soft and very soft textures (Table 4). KP samples with optimal texture were produced from light thighs (100%), soft KP samples were made from heavy (61%) and light (39%) thighs, and very soft KP samples were mainly produced from heavy pork thighs (66%). No significant differences were found in the texture type distribution of KP samples among suppliers (χ2=2.000, critical value χ2=3.841, df=1, p=0.157). However, since the goal of manufacturers is to produce a larger quantity of the final product, they want to use heavy pork thighs as raw material. To achieve this goal and reduce the undesirable texture of dry-cured hams, certain technological steps must be adapted.

Table 4

Composition of ranks of Kraški pršut (KP) hams according to sensory assessed texture.

| KP Ranks | Number of KP | Mass Class (pcs) | Supplier (pcs) |

|---|---|---|---|

| Optimal | 6 | Light (6) | A (2), B (4) |

| Soft | 23 | Light (9), Heavy (14) | A (9), B (14) |

| Very Soft | 3 | Light (1), Heavy (2) | A (1), B (2) |

It was assumed that major mass losses in the production of KP samples as a result of drying, ripening and, last but not least, the quality of meat with dark, firm, dry (DFD) or pale, soft, exudative (PSE) properties were related to the texture parameters and sensory attributes of the final product. However, the results of the correlation analysis showed the opposite phenomenon; the losses were not strongly related to the mentioned parameters of KP samples (Table 5). A positive correlation coefficient was found between KP sample mass and aroma (p≤0.01; r=0.27) and pastiness (p≤0.05; r=0.16), a negative correlation coefficient between KP sample mass and hardness (M) (p≤0.01; r=−0.32) and saltiness (p≤0.01; r=−0.41) as well TPA parameters (hardness (TPA), springiness, cohesiveness, chewiness and resilience) (p≤0.01; r=−0.22 to −0.33) and a very strong correlation with NaCl content (p≤0.01; r=−0.80). The lighter hams were harder and saltier, more cohesive and chewier than the heavier hams. Similar relationships as for the KP sample mass were also found for the mass of pork thighs.

Table 5

Coefficients of Pearson correlations between production parameters, physicochemical parameters, instrumental texture profile analysis (TPA) parameters and sensory attributes of Kraški pršut (KP) hams (n=192).

| Parameter | Pork thigh massa | Mass lossa | KP massa | NaCl | NPN | PI |

|---|---|---|---|---|---|---|

| Hardness (M) | −0.34** | −0.03 | −0.32** | 0.25** | 0.00 | −0.02 |

| Pastiness | 0.18* | −0.09 | 0.16* | −0.10 | 0.17* | 0.17* |

| Solubility | −0.02 | 0.10 | −0.05 | 0.00 | 0.05 | −0.05 |

| Odour | 0.10 | 0.07 | 0.08 | −0.16* | −0.03 | −0.10 |

| Aroma | 0.27** | 0.00 | 0.27** | 0.35** | −0.06 | −0.16* |

| Saltiness | −0.38** | 0.17* | −0.41** | 0.53** | 0.06 | 0.04 |

| Hardness (TPA) | −0.27** | 0.01 | −0.29** | 0.31** | −0.08 | −0.03 |

| Adhesiveness | −0.13 | 0.00 | −0.17* | 0.20** | −0.06 | −0.08 |

| Springiness | −0.26** | 0.18* | −0.22** | 0.10 | −0.03 | −0.18* |

| Cohesiveness | −0.30** | 0.21** | −0.30** | 0.22** | −0.07 | −0.20** |

| Chewiness | −0.33** | 0.05 | −0.33** | 0.31** | −0.07 | −0.10 |

| Resilience | −0.26** | 0.12 | −0.24** | 0.13 | −0.09 | −0.18* |

| NaCl | −0.62** | −0.15 | −0.80** | 1 | −0.03 | −0.06 |

| NPN | −0.06 | −0.06 | −0.09 | −0.03 | 1 | 0.60** |

| PI | −0.16* | −0.02 | −0.02 | −0.04 | 0.60** | 1 |

The NPN content is interesting because it is an indicator of the extent of ripening, tenderizing and aroma development of the final product. In the correlation analysis between the NPN content and the texture parameters, a positive coefficient and very weak correlation was found for pastiness (p≤0.05; r=0.17) (Table 5). For the PI, the same finding was noticed for pastiness and a negative correlation coefficient with aroma as well as TPA parameters (springiness, cohesiveness and resilience) (p≤0.05; r=–0.20 to –0.16).

CONCLUSIONS

Physicochemical properties, instrumental texture profile analysis parameters and sensory attributes have contributed to classifying Kraški pršut as optimal (19%), soft (72%) and very soft (19%). The correlation between the texture of KP samples, the degree of proteolysis and mass loss during production cannot be fully demonstrated; therefore, increasing the level of drying hams to a higher mass loss does not ensure a better texture of the product. However, in the present study, the mass of KP samples was negatively related to saltiness and hardness (determined by both sensory and instrumental analysis), and positively related to pastiness and aroma, with the light hams being harder and saltier but less pasty and aromatic than the heavy ones. Thus, to achieve the optimal texture of dry-cured ham Kraški pršut, certain technological steps must be adapted. The use of light thighs is one of the solutions, and it is better if producers adjust/ divide the whole production scheme, starting from the separation of the thighs by weight, limiting dehydration and extending the ripening phase.