INTRODUCTION

Wheat flour, containing gluten, is commonly used in bakery and pasta items due to its unique properties. The presence of gluten within wheat flour contributes to the strength and elasticity of dough, resulting in a well-structured final product. Gluten is comprised of two main protein fractions: glutenins and gliadins [Kamal et al., 2023]. Glutenins contain intra-molecular disulfide bonds in their structure, their structure tends to be linear, and this protein fraction is insoluble in alcohol. While gliadins, soluble in alcohol, have inter- and intra-molecular bonds and their structure tends to be spherical and dense [Li et al., 2021]. Gliadins and glutenins bind and make the dough more elastic, thus facilitating the forming process and making the dough fluffier [Li et al., 2020]. Apart from its advantages, gluten can trigger celiac or proximal enteropathic conditions associated with reversible immune reactions. Individuals with celiac disease experience inflammation in the small intestine due to an adverse response to gluten ingestion, damaging the intestinal lining [Zerbini et al., 2024]. In Indonesia, wheat flour is extensively utilized in diverse food preparations, serving as a significant source of calories.

However, individuals with autoimmune disorders, gluten ataxia, wheat allergy, non-celiac gluten sensitivity (NCGS), and dermatitis herpetiformis must also avoid gluten-containing foods [Singla et al., 2024]. Hence, substituting wheat flour with gluten-free alternatives becomes imperative.

Certain gluten-free indigenous tubers include cassava and suweg. Cassava, scientifically known as Manihot esculenta Crantz., is a tropical plant species native to regions across Asia, Africa, and South America [Burns et al., 2012]. Indonesia is the largest cassava producer in the world. Among its various uses, cassava can be processed into cassava flour. However, utilizing gluten-free flour as a replacement for wheat flour poses several challenges. Typically, products made from gluten-free flour lack the desirable characteristics found in wheat flour-based products. One strategy to broaden the application of gluten-free flours involves modifying the starch in the flour. Several studies into the chemical, physical and microbial modifications of starch structure aimed to improve its characteristics have been reported [Cahyana et al., 2020; Li et al., 2023; Liu et al., 2022; MagallanesCruz et al., 2023; Marta et al., 2019a,c; Marta et al., 2022; Xu et al., 2021; Zhang et al., 2021; Zheng et al., 2020]. In the case of cassava flour, Liu et al. [2022] produced modified cassava flour (MCF) by fermentation. MCF had a neutral aroma and good nutritional values with carbohydrate content of 87.55 g/100 g, proteins at 2.03 g/100 g, lipids at 0.43 g/100 g, ash at 0.85 g/100 g, and crude fiber at 4.17 g/100 g.

Suweg (Amorphophallus paeoniifolius (Dennst.) Nicolson), a member of the Araceae family, represents a gluten-free tuber commodity indigenous to Indonesia. However, its utilization is currently restricted due to the limited range of products derived from suweg. Processing suweg tubers into flour offers a viable solution for expanding the potential applications of suweg tubers. Suweg flour is rich in carbohydrates (76.32–78.36 g/100 g) and proteins (10.14–11.37 g/100g), and its ash and fat content is 2.30–3.22 g/100 g and 0.49–0.55 g/100 g, respectively [Suriya et al., 2016].

A flour blend is a mixture of different flours rich in starch, protein, and other nutrients with or without wheat flour [Fetriyuna et al., 2021; Kılıç Keskin et al., 2022; Shittu et al., 2007]. Flour blending aims to improve the final product’s characteristics such as sensory characteristics, nutritional content, functional properties, etc. by combining the benefits of each flour. In this study, modified cassava flour and suweg flour were used as a flour blend to replace wheat flour in steamed brownies. Modified cassava flour offers the advantage of being gluten-free, suitable for individuals with gluten intolerance or celiac disease, and its high fiber content [Liu et al., 2022]. However, it lacks the binding properties of gluten, which may affect the texture of the final product. On the other hand, our previous study showed that suweg flour is rich in fiber and nutrients, and provides a natural sweetness to baked goods [Marta et al., 2023]. Additionally, the neutral taste of modified cassava flour complements the distinct flavor of suweg flour, resulting in a more harmonious flavor profile.

Several studies have been conducted on steamed brownies that used local commodities as a substitute for wheat flour.

Previous studies have reported that steamed brownies from 100% modified cassava flour [Lubis et al., 2021] and 100% pumpkin flour [Subaktilah et al., 2021] had lower protein contents. Furthermore, Lubis et al. [2021] reported that steamed brownies with a flour blend from breadfruit flour, purple sweet potato flour, modified cassava flour, and saga seed flour with a ratio of 35:45:5:15 (w/w/w/w), had weaker aroma and good volume expansion compared to wheat flour steamed brownies. Meanwhile, steamed brownies with 100% suweg flour [Bela Monica & Setyaningrum, 2022] and 100% purple sweet potato flour [Lubis et al., 2021] produced a dark color and dense texture. Information regarding the use of modified cassava and suweg flours in making gluten-free steamed brownies is still limited; hence, the aim of this study was to evaluate the physicochemical properties of modified cassava and suweg flour blends in various proportions and to determine textural and sensory characteristics of gluten-free steamed brownies produced from these blends.

MATERIALS AND METHODS

Materials

The main materials used in this study were commercial medium wheat flour (Segitiga Biru by Bogasari Flour Mills, Indofood Sukses Makmur, Jakarta, Indonesia), commercial cassava flour modified by fermentation (Ladang Lima by Agung Bumi Agro, Surabaya, Indonesia), and suweg tubers with a harvest age of 1 year (Madiun, East Java, Indonesia). Additional ingredients for making steamed brownies were: cocoa powder (Van Houten by PT Perusahaan Industri Ceres, Bekasi, Indonesia), salt (Cap Kapal by Susanti Megah, Surabaya, Indonesia), powdered sugar (Gulaku by Sugar Group Companies, Lampung Tengah, Indonesia), emulsifier and baking powder (Koepoe Koepoe by Gunacipta Multirasa, Tangerang, Indonesia), margarine (Blue Band by Unilever Indonesia Tbk, Bandung, Indonesia), chicken eggs (Eggspert, Bandung, Indonesia), and a dark chocolate compound (Collata by Gandum Mas Kencana, Tangerang, Indonesia).

Suweg flour preparation

The suweg flour (SF) was prepared according to the method provided in Marta et al. [2019a] with a slight modification. The suweg tubers were peeled manually using a knife to carefully remove the skin in thin layer, and sliced (±1 mm) using a food processor. The chips were soaked in water to inhibit the browning reaction. Then, they were drained and dried in a drying oven at 50°C overnight. The dried chips were then milled and sieved using a 100-mesh sieve.

Flour blend preparation

A flour blend was prepared by mixing two types of single flour, modified cassava flour (MCF) and suweg flour (SF), until homogeneous. The ratios of MCF and SF (by weight) used in flour blends were 80:20 (F1), 70:30 (F2), and 60:40 (F3).

Brownie preparation

The preparation method for steamed brownies followed that described by Lubis et al. [2021] with a slight modification. First, the dry ingredients, such as flour blend or wheat flour (WF), powdered sugar, cocoa powder, baking powder, and salt, were mixed until homogeneous in a container (mixture 1). Then, the eggs were beaten and mixed with an emulsifier at the highest mixer speed in another container for 15 min or until stiff peaks were produced (mixture 2). Afterward, the dry ingredients were gradually stirred with mixture 2. The melted margarine and dark chocolate were added and stirred until homogeneous. The mixture was poured into the pan (21×9×7 cm2) and then steamed for 45 min. Formulations of steamed brownies are presented in Table 1. Gluten-free steamed brownies prepared using F1, F2 and F3 were coded as GFSB-F1, GFSB-F2 and GFSB-3 respectively. Steamed brownie with wheat flour (WFSB) served as the control. All brownie variants were prepared in three repetitions.

Table 1

Formulation (g) of wheat flour-based steamed brownies (control) and gluten-free steamed brownies with modified cassava and suweg flour blends in different flour proportions (80:20, 70:30 and 60:40 by weight).

Analysis of proximate composition and crude fiber content of flours

The proximate composition and crude fiber content were analyzed according to AOAC International methods [AOAC, 2005]. Moisture content was determined using an oven-drying method, drying at 135°C for 2 h (method no. 930.15). Ash content was determined by incinerating the flour sample in a furnace (method no. 930.05). Lipid content was determined using the Soxhlet extraction (method no. 930.09). Protein content was determined using the Kjeldahl method (method no. 978.04). Crude fiber content was determined using method no. 978.10. The contents of ash, lipids, proteins and crude fiber were expressed in g per 100 g of dry base (db) of flour blend or wheat flour.

Analysis of pasting properties of flours

A Rapid Visco Analyzer (RVA StarchMaster2, Parten Instruments, Warriewood, Australia) was used to determine the pasting properties of flours. The flour samples (2.8 g) were added to 25 mL of distilled water in an RVA canister. The temperature was initially held at 50°C for 1 min, then increased from 50 to 95°C at a rate of 6°C/min, kept at 95°C for 5 min, and then decreased to 50°C at a rate of 6°C/min. Finally, the gel was held at 50°C for 5 min. The visco-amylograms were recorded and several parameters were calculated, including pasting temperature (PT), peak viscosity (PV), holding viscosity (HV), breakdown (BD), final viscosity (FV), and setback (SB). PT was the temperature at which the viscosity increases during the heating process. PV was the highest viscosity reached during the heating phase of a pasting curve. HV was the minimum viscosity reached after the PV during the cooling phase. FV was the viscosity at the end of the pasting curve after the sample has cooled down. BD was the decrease in viscosity from PV to HV during the heating phase and was calculated by subtracting HV from PV. SB was the increase in viscosity after reaching PV and cooling the sample. SB was calculated by subtracting PV from FV.

Color evaluation of flours and steamed brownies

The color parameters were measured using a CM-5 spectrophotometer (Konica Minolta Co., Osaka, Japan) with Spectra Magic software. The color measurement included lightness (L*), rednessgreenness (a*), yellowness-blueness (b*), and hue. The calibration was performed with a white calibration plate (CM-A120) and a zerocalibration plate (CM-A124) using a large target mask (CM-A203). The whiteness index and color difference (ΔE) for flours and steamed brownies were calculated according the Equations (1) and (2) previously used by Chaple et al. [2020] and Diaz et al. [2019], respectively.

where: the ΔL*, Δa*, and Δb* are the differences between the color parameters of the sample and the control: wheat flour (for flour blends) and wheat flour-based steamed brownie (for gluten-free brownies).Determination of functional properties of flours

Swelling volume (SV), solubility (SOL), and water absorption capacity (WAC) of flours were determined. The SV and SOL were assessed following the previous method by Marta et al. [2019b]. The flour (0.35 g on a dry basis) was placed into a centrifuge tube, followed by the addition of 12.5 mL of distilled water. The mixture was vortexed for 20 s, then heated in a water bath at 92.5°C with regular stirring for 30 min. Subsequently, the sample was swiftly cooled for 1 min in an ice water bath and then centrifuged at 2,050×g for 15 min. The resulting supernatant was carefully decanted, and its volume was recorded. To determine solubility, the supernatant was dried in an oven, and the solubility percentage was calculated. SV and SOL were calculated using the Equations (3) and (4):

WAC was evaluated using the following procedure: 1 g of the flour was combined with 10 mL of distilled water in a centrifuge tube and mixed thoroughly using a vortex mixer. Afterward, the sample was allowed to condition at room temperature (26±2°C) for one hour before being centrifuged at 2,050×g for 30 min. The volume of the resulting supernatant was recorded, and the WAC was calculated using Equation (5):

Volume expansion test of steamed brownies

The volume expansion test procedure referred to Gandikota & MacRitchie [2005] with a slight modification. The percentage of volume expansion was calculated based on the final volume of steamed brownies (after steaming) and the initial volume of the mixture (before steaming). Initial and final volumes were calculated by multiplying the length, width and height of the dough and brownies, respectively. Volume expansion was calculated using Equation (6):

Evaluation of texture parameters of steamed brownies

Texture parameters were evaluated using a texture analyzer (TA.XTExpress, Stable Micro System, Godalming, UK) and Exponent Lite Express software for data collection and calculation. The brownie samples (2×2×3 cm3) were pressed using an aluminum cylinder probe P36R with a 2 kg load cell, distance of 10 mm, force of 5 g, strain of 50%, and 5 mm/s speed for 5 s. Their hardness, springiness, cohesiveness, gumminess, chewiness, and resilience were measured.

Hedonic sensory test of steamed brownies

A hedonic sensory test of the brownies was conducted with 60 semi-trained participants aged between 19 and 24, consisting of men and women. Steamed brownies were served in size (2×2×3 cm3) from the center and placed on white plastic dishes coded with random three-digit numbers. Steamed brownies were evaluated based on the acceptability of their color, texture, aroma, taste, and overall acceptance using a 7-point hedonic scale. The scale ranged from “like very much” to “dislike very much,” corresponding to the highest and lowest scores of “7” and “1”, respectively. This test procedure refers to Lubis et al. [2021].

Statistical analysis

Data were expressed as mean and standard deviation (SD) of triplicates. The data were analyzed using the one-way analysis of variance (ANOVA), followed by the Duncan test to determine the significance of differences at p<0.05. The IBM SPSS 27.0 statistical software (Armonk, NY, USA) was used for statistical analyses.

RESULTS AND DISCUSSION

Proximate composition and crude fiber content of flours

The proximate composition and crude fiber content of flour blends and wheat flour are presented in Table 2. The ash content of flour blends was higher than that of wheat flour. Flour blends contained 1.64–2.38 g of ash in 100 g db, and showed the following dependency: the higher the proportion of suweg flour (SF) in the blend, the higher the ash content of the flour. In contrast, the lipid and protein contents of flour blends were lower than those of wheat flour. The protein content of wheat flour was up to 10 times higher than of flour blends. The flour blends with the increasing share of SF were characterized by increasing protein contents. A previous study has reported that SF had a higher protein content than MCF, where the protein content of SF and MCF are 44.4% db and 1.13% db, respectively [Marta et al., 2023].

Table 2

Proximate composition and crude fiber content of wheat flour and flour blends with different ratios of modified cassava flour (MCF) to suweg flour (SF).

| Flour | Water (g/100 g db) | Ash (g/100 g db) | Lipid (g/100 g db) | Protein (g/100 g db) | Crude fiber (g/100 g db) |

|---|---|---|---|---|---|

| Wheat flour* | 14.52±0.16 | 0.69±0.01 | 1.36±0.43 | 10.55±0.18 | 0.38±0.15 |

| F1 | 11.37±0.15a | 1.64±0.02c | 0.55±0.03c | 1.34±0.06c | 0.86±0.18c |

| F2 | 11.16±0.25a | 2.00±0.02b | 0.67±0.16b | 1.61±0.22b | 1.48±0.09b |

| F3 | 10.86±0.53a | 2.38±0.04a | 0.78±0.06a | 1.88±0.01a | 1.91±0.04a |

* Values for wheat flour were previously published [Marta et al., 2023]. Means within columns with different superscripts are significantly different (p<0.05). F1, MCF to SF ratio of 80:20 (w/w); F2, MCF to SF ratio of 70:30 (w/w); F3, MCF to SF ratio of 60:40 (w/w); db, dry base.

All flour blends had a higher crude fiber content than wheat flour (Table 2). This difference can be important when considering the baking properties of flour blends affecting the gluten-free steamed brownies prepared from them. A previous study has reported that the lower volume expansion of muffins might be due to the higher crude fiber content in wheat and flaxseed flour blend [Kaur & Kaur, 2018].

Pasting properties of flour blends

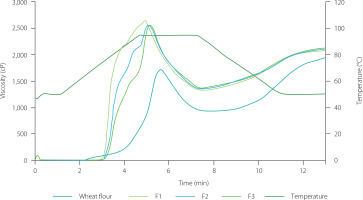

The visco-amylograms and pasting parameters of flours are presented in Figure 1 and Table 3, respectively. The pasting temperature (PT), peak viscosity (PV), and breakdown (BD) of flour blends were higher than these of the wheat flour; conversely, the setback (SB) of flour blends was lower than that of the wheat flour. PT, PV, and SB of F1 significantly (p<0.05) differed from the other flour blends. It had a lower PT and higher PV and SB than the other flour blends. The higher the PT of blends with higher suweg flour proportion could be caused by the increasing content of non-starch components in the flour blends (Table 2).

Figure 1

Visco-amylograms of wheat flour and flour blends (F1, F2 and F3) with different ratios of modified cassava flour to suweg flour (80:20, 70:30 and 60:40 by weight, respectively).

Table 3

Pasting properties of wheat flour and flour blends with different ratios of modified cassava flour (MCF) to suweg flour (SF).

| Flour | Pasting temperature (°C) | Peak viscosity (cP) | Hold viscosity (cP) | Final viscosity (cP) | Breakdown (cP) | Setback (cP) |

|---|---|---|---|---|---|---|

| Wheat flour* | 64.91±0.60 | 1,718±5 | 936±15 | 1,943±24 | 783±10 | 1,007±10 |

| F1 | 73.11±0.82b | 2,656±11a | 1,327±43c | 2,088±26b | 1,329±52a | 761±30a |

| F2 | 74.34±0.45a | 2,579±8b | 1,356±53b | 2,111±25ab | 1,222±61b | 755±33b |

| F3 | 74.53±0.24a | 2,576±33b | 1,381±30a | 2,134±21a | 1,195±52c | 753±18b |

* Values for wheat flour were previously published [Marta et al., 2023]. Means within columns with different superscripts are significantly different (p<0.05). F1, MCF to SF ratio of 80:20 (w/w); F2, MCF to SF ratio of 70:30 (w/w); F3, MCF to SF ratio of 60:40 (w/w).

Non-starch components, such as protein, lipid, and fiber, can inhibit starch gelatinization which needs more energy to gelatinize, and increase the PT [Yang et al., 2021]. On the other hand, the presence of the non-starch components decreased the PV, BD, and SB of flour blends.

The higher BD and the lower SB of all flour blends compared to the wheat flour indicated that these flours have lower thermal stability and do not retrograde easily, respectively [Charles et al., 2016]. Flour with low SB is desirable for making steamed flour products because it is not easily retrogradable, so its texture quality is more stable during storage [Li et al., 2024]. Retrogradation refers to the process where starch molecules in baked goods reorganize themselves into a more crystalline structure, leading to staling and changes in texture over time. Flour with low SB can maintain steamed brownies’ soft and moist texture for longer, improving their quality during storage.

Color of flours

The color parameters of wheat flour and flour blends are shown in Table 4. The L*, hue, and whiteness index (WI) of flour blends were lower than those of wheat flour, while a* was higher. Significant (p<0.05) differences existed in the color parameters of flour blends, except for the b* value between F2 and F3. F1, consisting of 80% MCF and 20% SF, displayed higher L*, hue, and WI compared to the other flour blends, whereas its a*, b*, and ΔE were lower. Increasing the proportion of MCF in the flour blend resulted in higher L*, hue, and WI, as well as lower a* and b*. The ΔE represents the color variation between wheat and blend flours, ranging from 3.85 to 6.33 with the lowest value for F1, indicating closer color similarity to wheat flour.

Table 4

Color parameters of wheat flour and flour blends with different ratios of modified cassava flour (MCF) to suweg flour (SF).

| Flour | L* | a* | b* | Hue | Whiteness index | ΔE |

|---|---|---|---|---|---|---|

| Wheat flour* | 93.09±0.21 | 0.45±0.01 | 9.81±0.12 | 1.53±0.01 | 87.99±0.03 | – |

| F1 | 89.36±0.03a | 1.29±0.01c | 9.29±0.06b | 1.43±0.00a | 85.82±0.03a | 3.85±0.23c |

| F2 | 87.94±0.03b | 1.52±0.01b | 9.60±0.08a | 1.42±0.01b | 84.51±0.06b | 5.26±0.19b |

| F3 | 86.88±0.08c | 1.68±0.03a | 9.76±0.09a | 1.40±0.00c | 83.56±0.12c | 6.33±0.22a |

* Values for wheat flour were previously published [Marta et al., 2023]. Means within columns with different superscripts are significantly different (p<0.05). F1, MCF to SF ratio of 80:20 (w/w), F2, MCF to SF ratio of 70:30 (w/w), F3, MCF to SF ratio of 60:40 (w/w); L*, lightness; a*, redness-greeness; b*, yellowness-blueness; ΔE, color difference compared to wheat flour.

Color is crucial in consumer acceptance of food products, as it is typically the first perceived sensory aspect. A higher proportion of SF in the flour blend led to a lower whiteness index (WI), which in turn negatively correlated with an ash content. Previous research has shown that higher ash content of chickpea, carob and rice flours determined their lower brightness [Ammar et al., 2022]. In addition, the phenolics can cause color changes due to forming oxidation products, imparting a brown color to flour [Shete et al., 2015].

Functional properties of flours

The functional properties of flours, including swelling volume, solubility, and water absorption capacity (WAC) are shown in Table 5. Flour blends exhibited higher swelling volume, solubility, and WAC compared to wheat flour. While the functional properties of all flour blends were generally similar, there was a notable difference in WAC. The WAC of F1 was significantly (p<0.05) higher than that of F2 and F3.

Table 5

Functional properties of wheat flour and flour blends with different ratios of modified cassava flour (MCF) to suweg flour (SF).

| Flour | Swelling volume (mL/g) | Solubility (%) | WAC (g/g) |

|---|---|---|---|

| Wheat flour* | 11.53±0.32 | 14.17±2.00 | 0.95±0.11 |

| F1 | 19.70±0.71a | 14.27±0.79a | 1.98±0.06a |

| F2 | 19.58±0.38a | 14.21±0.62a | 1.66±0.07b |

| F3 | 19.06±0.37a | 13.81±0.45a | 1.65±0.05b |

* Values for wheat flour were previously published [Marta et al., 2023]. Means within columns with different superscripts are significantly different (p<0.05). F1, MCF to SF ratio of 80:20 (w/w); F2, MCF to SF ratio of 70:30 (w/w); F3, MCF to SF ratio of 60:40 (w/w); WAC, water absorption capacity.

The lower swelling volume (SV) observed in wheat flour compared to flour blends could be attributed to its higher lipid and protein contents. Non-starch components such as lipids and proteins can inhibit water absorption and starch swelling [Cahyana et al., 2021; Chao et al., 2020; Marta et al., 2019b]. Cahyana et al. [2021] reported that the lipids could interact with starch to form a starch-lipid complexes, where the presence of protein promoted the formation of these complexes. The formation of starch-lipid complexes hindered the starch swelling.

Volume expansion of steamed brownies

The volume expansion of wheat flour-based steamed brownies and gluten-free steamed brownies is presented in Table 6. All variants of gluten-free steamed brownies (GFSB-F1, GFSB-F2, and GFSB-F3) exhibited a lower volume expansion compared to wheat flour-based steamed brownies (WFSB). The presence of gluten in WFSB notably contributed to its higher volume expansion. Additionally, the volume expansion in steamed brownies can be enhanced by using baking powder and resulting production of CO2 during the heating or steaming process [De Leyn, 2014]. Apart from incorporating baking powder, various factors such as mixing technique, heat distribution, egg beating, and the characteristics of the pan significantly influence the volume expansion of steamed brownies. Furthermore, in addition to the absence of gluten, the reduced volume expansion observed in gluten-free steamed brownies (GFSB) can also be attributed to their high fiber content [Rai et al., 2018].

Table 6

Volume expansion and texture parameters of wheat flour-based steamed brownies (WFSB) and gluten-free steamed brownies (GFSB) prepared with modified cassava and suweg flour blends (F1, F2 and F3) in different flour proportions (80:20, 70:30 and 60:40 by weight, respectively).

Texture parameters of steamed brownies

The texture analysis of steamed brownies in this study encompassed hardness, springiness, cohesiveness, gumminess, chewiness, and resilience (Table 6). In the case of all texture parameters, gluten-free steamed brownies showed lower values compared to the wheat flour-based steamed brownies, except for hardness, where GFSB-F2 and GFSB-F3 exhibited higher levels than WFSB. Among the GFSB, an increase in the proportion of SF in flour blends corresponded to higher values of texture parameters, except for springiness and resilience. It suggests that SF primarily influences the enhancement of texture parameters in GFSB.

The SF in flour blend causes an increase in the hardness of GFSB, which might be due to the high content of crude fiber in SF. Suweg flour contains 3.15 g of crude fiber in 100 g, which is higher than in MCF (1.18 g/100 g) [Marta et al., 2023]. Furthermore, the higher the SF proportion in the blend, the higher the cohesiveness, gumminess, and chewiness of GFSB. The high cohesiveness of the steamed brownies indicated that the product could retain more gas and volume. The texture attributes of GFSB-F2 were more similar to WFSB and did not exhibit significant differences (p≥0.05) compared to GFSB-F3. The increased gumminess and chewiness observed in GFSB with the higher SF content can be attributed to the crude fiber content of the flour. A previous study has indicated that incorporating more flour with a low fiber content led to brownies with reduced gumminess or excessive hardness [Lubis et al., 2021].

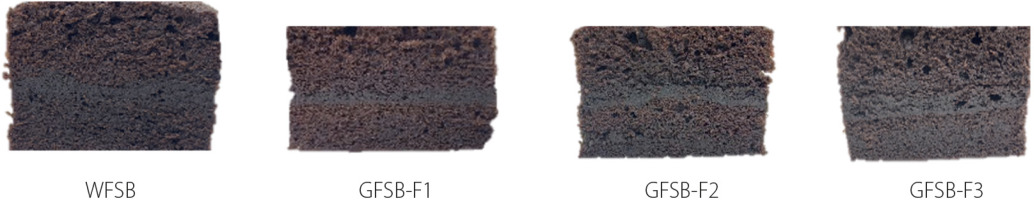

Color of steamed brownies

The appearance and color parameters of steamed brownies are presented in Figure 2 and Table 7, respectively. None of the color parameters of GFSB-F1 showed significant differences (p≥0.05) from WFSB. Moreover, an increase in the proportion of SF in the flour blend corresponded to higher values across all color parameters of GFSB, including L*, a*, b*, hue, and ΔE.

Figure 2

The visual appearance of wheat flour-based steamed brownies (WFSB) and gluten-free steamed brownies (GFSB) prepared with modified cassava and suweg flour blends (F1, F2 and F3) in different flour proportions (80:20, 70:30 and 60:40 by weight, respectively).

Table 7

Color parameters of steamed wheat flour-based brownies (WFSB) and gluten-free brownies (GFSB) prepared with modified cassava and suweg flour blends (F1, F2 and F3) in different flour proportions (80:20, 70:30 and 60:40 by weight, respectively).

The ΔE value signifies the color distinction between GFSB samples and WFSB (control). A ΔE value below 0.2 suggests no discernible difference in color between the two substances. A ΔE value ranging from 0.2 to 1.0 indicates a minor color variation, while a ΔE value between 1.0 and 3.0 suggests a slight color difference. A ΔE value of 3.0 to 6.0 denotes a moderate color difference, whereas a ΔE value exceeding 6.0 indicates a substantial color difference [Sharma, 2003]. The ΔE values of all GFSB ranged from 2.30 to 6.32 (Table 7). GFSB-F1 displayed the smallest ΔE value (2.30), indicating a slight color difference compared to WFSB. The ΔE value of GFSB corresponded with the ΔE value of flour blends, whereby an increase in SF proportion in the blend led to a higher color difference between the sample and the control.

The color of flour influences the color of steamed brownies. Steamed brownies typically exhibit a dark brown or blackish-brown hue, influenced by ingredients such as chocolate and sugar, as well as the baking process. Cocoa powder and chocolate bars are common chocolate sources in brownie recipes. Moreover, finer sugar particles absorb color more effectively, resulting in a darker brown shade [Richardson et al., 2018].

Hedonic sensory evaluation of steamed brownies

The results of the participants’ preference for steamed brownies are presented in Table 8. The hedonic attributes of GFSB did not significantly differ (p≥0.05) from WFSB, except for taste and overall acceptance preference of GFSB-F2. The taste and overall acceptance preference for GFSB-F2 were notably higher (p<0.05) than for WFSB and did not significantly differ (p≥0.05) from the other GFSB samples. Overall, all GFSBs received hedonic scores between 5 and 6, indicating they fell within the “like moderately” category and were generally accepted by the participants. MCF typically has a neutral aroma [Triyono et al., 2019]. As the proportion of SF increases, the distinct aroma of suweg tubers became more pronounced, enhancing the taste of GFSB. The aroma can also be intensified by the caramelization process occurring during baking, resulting in a distinctive caramel aroma. Moreover, the aroma can be further influenced by the Maillard reaction products and the quality and quantity of volatile compounds released [Capuano et al., 2009].

Table 8

Results of hedonic sensory test of wheat flour-based steamed brownies (WFSB) and gluten-free brownies (GFSB) prepared with modified cassava and suweg flour blends (F1, F2 and F3) in different flour proportions (80:20, 70:30 and 60:40 by weight, respectively).

The texture parameters assessed by instrumental analysis for GFSB differed significantly from those of WFSB. However, the texture preference for GFSB did not significantly differ from WFSB. The texture preference for all steamed brownies ranged from 5.25 to 5.60 (Table 8), indicating a preference for “like slightly”. Interestingly, a parallel trend to ΔE was observed; although the ΔE value for all GFSB samples was significantly different, the results of the hedonic test showed that the color preferences for all GFSB and WFSB samples were not significantly different. The difference trend between the results of analysis using instruments (ΔE) and hedonic tests (color preferences) was also found in another study [Cahyana et al., 2020]. The color preference for all steamed brownies samples ranged from 5.85 to 6.20, which means “like moderately” (Table 8).

Organoleptic tests still play a crucial role, especially in food and beverage industries where sensory perception is central to product quality. While instruments can provide quantitative data, organoleptic tests offer qualitative insights and can assess overall consumer acceptability, which instruments alone may not capture. So, while instruments may be more sensitive in certain aspects, organoleptic tests remain essential for comprehensive product evaluation.

CONCLUSIONS

The ratio of modified cassava and suweg flour significantly affected various properties of flour blends, including their chemical composition, color characteristics, pasting and functional properties. Suweg flour notably contributed to increased ash, lipids, proteins, and crude fiber contents in the flour blend. As the proportion of suweg flour increased, peak, breakdown, and setback viscosities decreased. Water absorption capacity of flour blends decreased, and the color difference (compared to wheat flour) increased with a higher suweg flour content. Incorporating composite flour into gluten-free steamed brownies significantly influenced their properties. Gluten-free steamed brownies exhibited a lower volume expansion compared to wheat flour-based steamed brownies. Brownies made from the flour blend with a higher content of suweg flour displayed higher texture parameters, except for springiness and resilience. The color of GFSB prepared with the blend with a lower proportion of suweg flour was more similar to color of WFSB. Preference levels for color, aroma, and texture of GFSB did not significantly differ from WFSB. However, GFSB prepared with the modified cassava and suweg flours in the ratio of 80:20 (w/w) was preferred in taste and overall acceptance over WFSB. Overall, the study suggests that the ratio of modified cassava and suweg flours plays a crucial role in determining the chemical, physical, and sensory properties of flour blends and their respective glutenfree steamed brownies. The findings provide valuable insights for the development of gluten-free products with improved sensory attributes and consumer acceptance.