INTRODUCTION

Obesity is a chronic inflammatory condition that is characterized by an increase in total body fat. As many as 39% of world adults aged over 18 years are overweight, with 13% classified as obese [WOF, 2023]. The consumption of foods high in energy, fat, and simple carbohydrates, combined with a low fiber intake and a lack of balanced energy expenditure, can act as triggers for obesity [Lasimpala et al., 2021]. Alongside the prevalence of obesity, the risk of metabolic syndrome issues also increases, being an initial bridge to various non-communicable diseases. A high-fiber diet plays a critical role in controlling various health-related biomarkers, including blood glucose, blood pressure, cholesterol levels, and others [Khalid et al., 2022]. However, majority of adults globally consume less than 20 g of fiber per day [Stephen et al., 2017], whereas the recommended fiber intake for adult ranges from 25 to 29 g per day [Reynolds et al., 2019]. Fiber aids in smooth bowel movements and prevents constipation. It also forms a matrix with carbohydrates in food, slowing down digestion and glucose absorption to maintain stable blood glucose levels. Additionally, the fermentation of fiber in the large intestine helps maintain pH balance and gut microbiota, reducing the risk of colorectal cancer [Dhingra et al., 2012].

Purple sweet potato (Ipomoea batatas L.) is a common tuber found in Indonesia. It might be served as a staple food containing up to 2.01–3.87 g/100 g of fiber in their fresh matter. Even in the form of flour, purple sweet potatoes have a high fiber content of up to 11.9 g/100 g [Huang et al., 1999; Palupi et al., 2023]. Kidney bean (Phaseolus vulgaris L.) is a type of legume known for its nutritional value as 100 g of kidney bean flour contains 13.12 g of fiber [Palupi et al., 2023]. These two foods not only have a high fiber content, but they also contain proteins with noticeable essential amino acids [Audu & Aremu, 2011; Kurnianingsih et al., 2021]. According to Herreman et al. [2020], the combination of proteins of tubers and legumes represents one of the suitable plant-based amino acid profiles. Purple sweet potato was detected as poor in methionine [Kurnianingsih et al., 2020], whereas, among common legumes, kidney beans are considered high in methionine, i.e., 0.105 g/100 g [Margier et al., 2018].

A diet rich in fiber and high-quality protein can help people with obesity and pre-diabetes feel fuller for longer periods of time, improve their lipid profiles, and lose weight by lowering insulin resistance [Clark & Slavin 2013; Dhillon et al., 2016; Lesgards, 2023; Rebello et al., 2014; Starr et al., 2019]. As a result, this kind of diet is also linked to a lower risk of developing a number of diseases linked to the metabolic syndrome [Amankwaah et al., 2017; Glynn et al., 2022; Reynolds et al., 2020]. A previous study reported that a high-quality protein diet helped prevent cardiovascular disease and type II diabetes by ameliorating the blood lipid profile and insulin resistance index in obese middle-aged and older adults [Starr et al., 2019].

Considering the above, it seems reasonable to make an effort to formulate a product from purple sweet potatoes and kidney beans, which can serve as a source of fiber and valuable protein, increasing the feeling of satiety and reducing the need for additional meals that could lead to excessive caloric intake. A product that can be formulated using purple sweet potatoes and kidney beans is flakes. These products are typically consumed for breakfast due to their convenience [Priebe & McMonagle, 2016]. The aim of our research was to optimize the formulation of a high-fiber extrudate using purple sweet potatoes and kidney beans and characterize the nutritional, physical and sensory characteristics of the final product, as well as the satiety index after consumption, as part of an initiative to enhance fiber intake in the population.

MATERIALS AND METHODS

Materials

There were two main materials that have been used in this research, i.e., purple sweet potato and kidney bean. The variety of purple sweet potato was Ayamurasaki, which was procured from the local farmer in Dramaga, Bogor, Indonesia. In a single run of purple sweet flour, as many as 100 kg of tubers have been used. A common kidney bean (50 kg) was purchased from the local market (Bogor, Indonesia).

Production of purple sweet potato and kidney bean flakes

The production of flakes from purple sweet potato and kidney bean was consisting of three main stages, i.e., tuber flour production, legumes flour production, and ingredient mixing followed by extrusion. The production of purple sweet potato flour began with cleaning the sweet potatoes to remove any soil adhering to their skin. Once cleaned, the sweet potatoes were manually cut into medium-sized pieces (3×3 cm), which were then steamed at a temperature of 100°C for 20 min using a PM-3A steamer (Armfield, Bogor, Indonesia) with a capacity of approximately 15 kg of cut sweet potatoes. Subsequently, the steamed sweet potatoes were mashed using a planetary mixer (Gansons, Bombay, India) until smooth. The mass was then dried using a model T of double drum dryer (Simon Dryers, Nottingham, UK) at a temperature of 110°C. The drying process resulted in purple sweet potato sheets and various-sized pieces that were still slightly moist. Therefore, they were further dried in a cabinet dryer (Gelenkwellendienst H. Orth GmbH, Ludwigshafen, Germany) for a minimum of 90 min at 60°C. Once the sheets and pieces were completely dry, they were ground using a ZS A300 pin disc mill (Phoenix, Jakarta, Indonesia) to obtain purple sweet potato flour with a particle size <0.25 mm (screen with 60 mesh). A single batch of purple sweet potato flour yielded as much as 46% of the fresh tuber weight.

As for the production of kidney bean flour, the kidney beans were washed and sorted to remove poor quality beans, such as rotten, sprouted, broken, and dried before soaking at room temperature (approximately 25°C) for 30 min. The soaked kidney bean was boiled using a PM-3A steam jacket kettle (Armfield) for 60 min until softened. This boiling was performed to fully cook the beans and enhance the texture (softened), palatability, and ease the subsequent grinding. Subsequently, the cooked kidney bean was finely mashed using a planetary mixer (Gansons). The drying of mashed kidney bean was performed using a double drum dryer (Simon Dryers) and a cabinet dryer (Gelenkwellendienst H.), followed by further grinding using a ZS A300 pin disc mill (Phoenix), similar to the processing of purple sweet potato flour. The yield of obtaining flour from kidney beans was as much as 80%.

The development and testing of the purple sweet potato and kidney bean extrudate formulations were conducted as a trial-and-error process before producing the final extruded product. This stage aimed to assess the feasibility of the product concept and estimate formulas for the best quality products. The feasibility and the quality of the concept and formula were tested based on the qualitative sensory evaluation by the selected panelists who met International Organization for Standardization (ISO) standard of sensory panelist [ISO 8586:2014]. The results of this evaluation are shown in Table S1 in Supplementary Materials. The development and optimization also included determining the temperature and time of extrusion. The final formulas, F0, F1, F2, and F3 (with different ratios of sweet potato flour to kidney bean flour – 100:0, 80:20, 70:30, 60:40 (w/w), respectively), used to obtain extruded purple sweet potato and kidney bean products are presented in Table 1. The dry ingredients, such as purple sweet potato flour, kidney bean flour, rice flour, cornstarch, milk powder, and salt, were mixed until well blended. Separately, the liquid ingredients, such as water, oil, and emulsifier, were homogenously combined. Subsequently, all the ingredients were mixed together using a Ueno noodle machine (Siraitodai Fhutuu Tokyo Manufacture, Japan) before being fed into the Twinscrew Bex 2256 extruder (Berto Food & Beverage Processing Machines, Jakarta, Indonesia). This extruder features three different speed settings, i.e., auger, screw, and cutter. The auger, also known as the feeder screw, is located at the beginning of extrusion process and is responsible for feeding the raw material into the extruder. The screw is located inside the extruder barrel and plays an important role in melting, mixing, and shaping the material as it moves along the barrel. The cutter is located at the end of the extrusion process. The faster the cutter operates the smaller the size of the resulting product. The extrusion temperature, auger, screw, and cutter speed were monitored, as well as the selection of the appropriate mold during the development and optimization of the formulation. The optimal extrusion temperature has been achieved at 60°C for the third temperature setting, with the first and second temperature settings were turned off. This setting is suitable for raw materials with a water content of up to 15%. During the trial process, the optimal speed settings were also obtained for the auger, screw, and cutter, with speeds set at 40, 40, and 50 Hz, respectively, where 10 Hz equals to 600 rpm. Based on the formulas F0, F1, F2 and F3 (Table 1), four extrudates of purple sweet potato with kidney bean substitution (E0, E1, E2 and E3, respectively) were produced. The flakes were then cooled at room temperature (25°C) for 30 min before being packaged in aluminum foil using a sealer. These products were subsequently subjected to determination of color and texture characteristics, sensory evaluation, analysis of nutrients, shelf-life and satiety index. As many as three experiments were performed for physical, sensory, and nutritional analysis. While the assessment of shelf-life has been conducted through eight batches of experiments as eight time series experiment. Furthermore, as many as three batches of production have been carried out for satiety index assessment, with all batches being homogenized prior to the packing and testing.

Physical characteristics analysis

The analysis of the physical characteristics included the assessment of the color and texture of the extrudates. The color analysis was conducted using an AMT511 Chroma Meter (Amtast, Lakeland, FL, USA), which measures the color of the samples based on the CIELab system. This system provides color measurement results expressed in L*, a*, and b* coordinates, which represent lightness (dark-bright), redness (green-red), and yellowness (blue-yellow), respectively. The texture of the flakes was tested for hardness using a CT3-100 Brookfield texture analyzer (Brookfield, Toronto, Canada).

Nutrient content determination

The nutrient content analysis of purple sweet potato and kidney bean extrudates includes determining the moisture content using the gravimetric AOAC International method [AOAC 952.10, 2005], ash content using the gravimetric method [AOAC 923.03, 2005], lipid content using the direct extraction method with a Soxhlet apparatus [AOAC 922.06, 1922], protein content using the Kjeldahl method [AOAC 920.87, 1920], and total fiber content using the enzymatic-gravimetric method [AOAC 985.29, 2003]. Carbohydrate content was estimated on the basis of balance. Results of nutrient content were expressed based on dry matter (DM) of extrudates.

Sensory evaluation

The sensory evaluation consisted of two tests, i.e., quantitative descriptive analysis (QDA) and overall acceptance rating test, also known as the hedonic test. QDA has been done by involving 8 trained panelists which met the requirements specified by ISO standard [ISO 8586:2014]. In QDA, the assessors participated in a focus group discussion (FGD) to determine the representative attributes, attribute definitions, and the standard scales to be used. The panelists then quantified each attribute by using 10-point intensity scales (weak-strong intensity) in a separate testing booth and recorded their ratings on evaluation sheets. The gathered data was processed and presented in a radar chart format.

The overall acceptance rating test was conducted to determine how well the products were accepted by the panelists. In this test, the level of acceptance of each attribute was measured using a 9-point hedonic scale, with 1 being “dislike extremely” and 9 being “like extremely”. In this research, the observed attributes were appearance, aroma, finger-feel texture, taste, mouthfeel, aftertaste, and overall perception. The panelists involved at this test were 40 initiated assessors, who have previously conducted sensory evaluations and understand the rules of sensory testing but have not yet been selected as assessors.

Shelf-life estimation

The flakes were stored at three different temperatures, i.e., 25, 35, and 45oC, at 1 till 8 weeks to estimate their self-life. Only E3 has been used for shelf-life estimation. Sensory acceptability (S) of extrudate was used as a parameter defining changes during storage. Sensory evaluation of acceptability was performed by 8 selected assessors at 1–7 scale with following interpretation, 7 – equal or better to control, 6 – slight difference to control, 5 – more distinct difference but still acceptable, 4 – beginning to lose acceptability, 3 – more distinct loss of acceptability, 2 – very distinct loss of acceptability, and 1 – unacceptable. The control here was the fresh E3, which was produced on the day of testing. It has been assumed that the test food would start to lose acceptability at S4 or ln S=ln 4=1.386. The shelf-life was predicted based on the regression equation of each storage temperature. Temperature of 30oC was used to calculate the final estimated shelf-life [Hough, 2010].

Satiety index determination

The satiety index assessment has been approved by the Ethics Committee of IPB University in Bogor, Indonesia, with the approval number 857/IT3.KEPMSM-IPB/SK/2023. It was measured after consumption of the flakes with 0% kidney beans flour (E0) and with 40% kidney beans flour (E3) compared with commercial cereals and using white bread as the reference. White bread was made from flour (all-purpose flour/medium protein) (70.4 g/100 g), water (10.0 mL/100 g), sugar (6.3 g/100 g), shortening (4.5 g/100 g), sweet whey powder (4.2 g/100 g), salt (2.1 g/100 g), yeast (0.8 g/100 g), and whole milk powder (0.8 g/100 g). The design used in this study was a partial crossover study, where each subject was given isocaloric food with 240 kcal after 10 h fasting. The test foods were given four times on four different days, but on the same day, all subjects were given the same type of food. There was a 3-day interval or washout period between the test foods to allow the subjects’ physiological conditions to return to their baseline [Becker et al., 2022; Nolan et al., 2016].

A total of 16 subjects was included in the study, following Forde’s [2018] recommendation of requiring 15–18 subjects to compare satiety between products. The subjects participating in this research met the inclusion and exclusion criteria. The inclusion criteria were as follows: individuals with body mass index (BMI) in optimal range (BMI 18.5–22.9 kg/m2), man or woman aged between 20–22 years, willing to be interviewed and complete the questionnaire, not currently on any specific diet, willing to undergo measurements of body weight, height, body composition, and participate in all activities, and not allergic to nuts. On the other hand, the exclusion criteria were suffering from chronic illnesses or complications.

The data was obtained through the completion of questionnaires and direct measurements on the subjects. The primary data included subject characteristics (name, age, and gender), anthropometry (height and weight), satiety levels, as well as the macro-nutrient content of the test foods, (white bread, commercial cereals, extruded purple sweet potato, and extruded purple sweet potato with kidney bean). Data related to the subjects’ nutritional status was collected through direct measurements using a digital floor scale for body weight (HN-289, Omron, Kyoto, Japan) and a microtoise for height (GEA SH2A stature meter, Bogor, Indonesia). Data was collected through a visual analogue scale (VAS) satiety score questionnaire at 0, 30, 60, 90, 120, 150, and 180 min after consumption of the food products, which was then used to calculate the area under the curve for each flake type and compare it with the area under the curve for white bread to determine the satiety index (%) for each subject [Forde, 2018]. Moreover, the curve was calculated using a trapezoid system for satiety parameters including hunger, fullness, desire, and food intake. The curve was scaled in units of time of sampling (counted in hour) and fullness index, which was expressed as a ruler scale at mm. Therefore, the area under the curve was expressed as mm×h.

Statistical analysis

Data processing in this research was conducted using Excel 2010 for Windows software (Microsoft, Redmond, WA, USA) and Statistical Product and Service Solution (SPSS) 16.0 software (IBM, Armonk, NY, USA). The processed and analyzed data included the results of color and texture analysis, sensory evaluations, shelf-life estimation and nutrient content, as well as satiety index. The data was then subjected to one-way analysis of variance (ANOVA) using SPSS software (IMB) and further tested with Duncan post hoc test if significant effects were found among the treatments. Results of the analysis were considered significantly different if p<0.05.

RESULTS AND DISCUSSION

Formulation and processing

The key steps in optimizing the formula for extruded products with purple sweet potato and kidney bean were adjusting the composition of additional flours, reducing or eliminating certain ingredients, and controlling the moisture content of the raw dough. It was also important to optimize the extruder settings, including the extrusion temperature based on thermo-control and the rotations of the screw, auger, and cutter. For this purpose, a series of trial-and-error experiments were carried out. The selection of the extrusion temperature and machine speed settings was performed based on the optimization trials conducted as part of preliminary research. Thirteen trials (Table S1) were conducted to develop the formulation and determine the extruder’s auger, screw, and cutter rotations, as well as the dough’s moisture content to achieve an optimal product quality. The screw type and also its speed have a significant impact on the rheological properties of the final product [Tomaszewska-Ciosk et al., 2012].

During the development of the extrudate formula, liquid ingredients (water, oil and emulsifier) were added (Table 1). They played a vital role in the drying process during the extrusion and in forming a matrix between starch and protein present in the dough. When heated, the starch experiences high pressure during extrusion, causing the dough to expand as it exits the extruder, resulting in expanded products. Without the addition of water to the product, the extruded dough cannot fully be formed, leading to non-expansion or burnt dough, causing it to adhere inside the extruder and obstructing extrusion [Yacu, 2020]. On the other hand, excessive liquid level leads to a resulting product with a soggy or mushy texture. The addition of oil to the dough could increase the crispiness of the product and prevent hollowness in the final products. This is because oil can reduce the friction between the dough and the extruder screw, thus preventing a rapid increase in temperature due to mechanical friction in the extruder. In this study, based on the preliminary research, the optimal liquid percentage was determined to be 10% (w/w) with oil-to-water ratio of 1:4 (w/v).

Table 1

Formulas (F0–F3) of extrudates.

The extruder employed in this study was a double-screw extruder equipped with three thermo-controls. Temperature for extrusion was reached at 60oC regulated only on the third thermo-control of the machine. Meanwhile, thermo-controls 1 and 2 remined switched off. This configuration is suitable for dough with a water content of less than 15 g/100 g [Budi et al., 2016]. If the dough’s water content exceeds 15 g/100 g, all thermo-controls must be activated [Budi et al., 2016]. Trials conducted at higher temperatures (>60°C) resulted in a burnt product. The low heating setting was chosen as the flours used in this study were fully cooked during the flouring stages. Through experimentation, it was determined that the optimal settings for the auger and screw speeds during the extrusion process of this study were 40 Hz, while the cutter speed was set at 50 Hz. A detailed evaluation of the trials is provided in Table S1.

Physical, nutritional and sensory characteristics

The selected formulas (Table 1) were used to obtain extrudates based on purple sweet potato without or with kidney bean substitution. The physical, chemical and sensory characteristics of these products are shown in Table 2. As the percentage of kidney bean flour substitution increased in the extruded formulation, there was a corresponding increase in lightness (L*) and yellowness (b*), but a decrease in redness (a*) of products. The significant variances in extrudate color, particularly the reduced redness observed in the flakes with the higher bean portion. The presence of anthocyanin in purple sweet potatoes seemed the plausible reason for this phenomenon. These pigments, found in significant quantities in purple sweet potatoes (ranging from 3.31 to 13.9 mg/g), are known to influence coloration [Rodríguez-Mena et al., 2023]. Our prior investigation revealed that although some of these anthocyanins undergo degradation during flour extrusion, their presence remains notable in the end product [Palupi et al., 2023]. The hardness of the extrudates also varied depending on the proportion of kidney bean flour in the formula – higher kidney bean flour content led to a higher hardness (Table 2). Visually, the produced flakes in our study exhibited a dense consistency with a slightly flat, concave round shape and a slight porosity. The number of pores increased with the quantity of kidney beans used. It is worth noting that the extrusion process has a significant impact on the composition and physical appearance of the products [Lisiecka et al., 2021; Ménabréaz et al., 2021].

Table 2

Physical and nutritional characteristics of extrudates.

[i] E0, E1, E2, and E3, extrudates obtained on the basis of formulas with different ratios of sweet potato flour to kidney bean flour – 100:0, 80:20, 70:30, 60:40 (w/w), respectively; L*, lightness; a*, redness; b*, yellowness; DM, dry matter. Values with different superscript letters (a–d) in a row are significantly different at p<0.05.

A similar pattern was also observed in the content of key nutrients in the extrudates. With increased kidney bean substitution, the levels of ash (crude minerals), protein, lipid, and total fiber increase (Table 2). The extrudate with 40% bean substitution had the highest contents of crude minerals, protein, lipid, and fiber at 3.26, 13.20, and 0.87, 17.00 g in 100 g of dry matter (DM), respectively. It is worth paying attention to the content of soluble and insoluble fiber in the formulated flakes. Higher kidney bean flour substitution led to an increase in insoluble fiber content and a significant decrease in soluble fiber content (p<0.05). This phenomenon may be attributed to kidney beans’ higher total fiber content compared to purple sweet potatoes, which predominantly consists of insoluble fiber [Kan et al., 2017]. According to Leite et al. [2022], purple sweet potatoes contain fiber ranging from 6.5 to 12.6% of their dry matter, depending on the variety. The fiber content of purple sweet potatoes is primarily composed of cellulose, hemicellulose, and pectin, at 2.7, 3.6, and 0.47%, respectively [Yuansah & Laga, 2023]. In contrast, kidney beans are known to contain 26.3% fiber in their dry matter, primarily composed of cellulose and hemicellulose [Kan et al., 2017].

Flakes are a ready-to-eat food product that meets the nutritional needs of individuals seeking a convenient source of essential nutrients [Priebe & McMonagle, 2016]. This product is well-suited to be part of a breakfast menu. The breakfast menu is capable of satisfying 22.4% of the daily energy requirement and provides 32.7% of the daily protein requirement, 21.8% of the daily fat requirement, 21.5% of the daily carbohydrate requirement, and 33.6% of the daily dietary fiber requirement for adults aged 19–64 years, both males and females [Gibney et al., 2018]. A single breakfast serving of the extrudate with purple sweet potato and kidney bean optimized in our study (50 g), when accompanied by a glass of fresh cow’s milk, a boiled egg, and a medium-sized banana, can adequately fulfill the breakfast requirements of adults. This developed product is also suitable for consumption by children, as supported by previous studies indicating that children generally show a strong preference for extruded food products made from ingredients like potatoes, sweet potatoes, fruit extracts, and various cereals [Gumul et al., 2023; Natabirwa et al., 2020; Potter et al., 2013; Shah et al., 2019]. Children’s inclination toward crispy textures, visually appealing appearances, and easy-to-consume food products contributes to their acceptance [Natabirwa et al., 2020]. Past studies have utilized ready-to-eat extrudates as supplemental foods to enhance nutrient intake in children [Gumul et al., 2023; Natabirwa et al., 2020; Potter et al., 2013; Shah et al., 2019]. Furthermore, the extrudate obtained in our study from a formula with 40% replacement of purple sweet potato flour with kidney bean flour has a potential to be labeled as a high-fiber, source of protein, and low-fat food item. The cut off of each claim is 6, 12, 3 g per 100 g flakes, respectively [Indonesian Food and Drug Authority 2022].

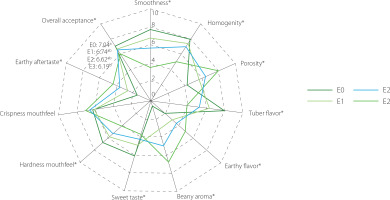

The result of QDA showed that the higher portion of the purple sweet potato flour in the extrudate formula provided a greater smoothness and homogeneity, a reduced porosity, a stronger tuber flavor with a milder earthy and beany undertone, and a sweeter taste of the final products (Figure 1). Additionally, it was noted that the purple sweet potato resulted in a harder mouthfeel and a less earthy aftertaste. Purple sweet potato contributed to sweet taste and tuber flavor. Moreover, the significant content of carbohydrate in purple sweet potato [Kurnianingsih et al., 2020] seemed to support the consistency of the mixture, making its texture smoother. While, the kidney bean contributed to the beany and earthy flavor. The substitution of kidney beans at 20%, 30%, and 40% did not significantly influence (p≥0.05) the overall acceptance level (Figure 1), with acceptance ratings consistently above six on a nine-point hedonic scale, corresponding to a “like moderately” according to the categorization proposed by Wichchukit & O’Mahony [2014]. Consequently, the extrudate with 40% kidney bean (E3) substitution was further evaluated for shelf-life and satiety index. The extrudate without a bean substitute and commercially available breakfast cereals were used for comparison.

Figure 1

Quantitative descriptive analysis (QDA) results and overall acceptance rating of extrudates (E0, E1, E2, and E3) obtained on the basis of formulas with different ratios of sweet potato flour to kidney bean flour – 100:0, 80:20, 70:30, 60:40 (w/w), respectively. *, Significantly different at p<0.05. Values of overall acceptance with different superscript letters are significantly different at p<0.05.

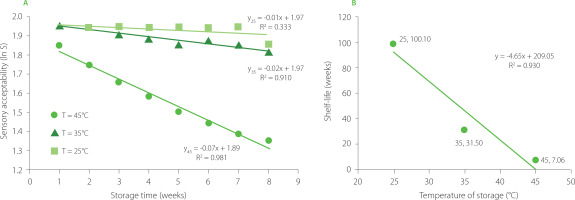

Shelf-life estimation

Determining the shelf-life of a food product is a critical step before it is introduced to consumers. This process is essential to ensure food safety, protect consumers, and maintain product quality. In this study, the shelf-life estimation was conducted using a sensory approach, which is known for its sensitivity compared to other methods [Hough, 2010]. A first-order kinetic reaction was chosen as the model for shelf-life estimation. Like many common foods, the developed product experiences a faster rate of deterioration as storage time and temperature increase (Figure 2). The correlation between these factors was particularly pronounced at higher storage temperatures. The equation with a lower slope was derived for 45°C (y = −0.0716x + 1.8891), in contrast to the equations for 35°C and 25°C, which were y = −0.0184x + 1.9667 and y = −0.0075x + 1.9684, respectively. By applying these formulations, a shelf-life estimation graph was constructed for different temperatures, resulting in the final equation: y = −4.6472x + 208.84. Assuming that the anticipated storage temperature will be around 30°C, the estimated safe storage time was 19 months. This is a favorable estimation, indicating that the developed product can be stored at room temperature for over a year without a significant reduction in acceptability.

Figure 2

Sensory acceptability on eight storage times (A) and estimated shelf-life (B) of the extrudates made of purple sweet potato flour with kidney bean flour substitution. T, temperature of storage; S, sensory acceptability at 1–7 scale with the following interpretation: 7 – equal or better to control, 6 – slight difference to control, 5 – more distinct difference but still acceptable, 4 – beginning to lose acceptability, 3 – more distinct loss of acceptability, 2 – very distinct loss of acceptability, and 1 – unacceptable; the test food start to lose acceptability at S=4 or ln S=ln 4=1.386. Control sample, the fresh E3 which was produced on the day of testing.

Satiety index

The satiety index serves as a measure of how filling and satisfying a food is, and it provides valuable information into its potential to control hunger and regulate food intake. This experiment enabled the researchers to compare the satiety effects of the test foods, providing insights into their potential as satisfying food options. Many factors contributed to the satiety index, one of them being nutrient content. Between products examined in our study, commercial cereals had the highest energy value (370 kcal/100 g) and total carbohydrate content (83.14 g/100 g) (Table 3). In contrast, the extruded purple sweet potato with kidney bean had the highest protein content (12.5/100 g) and higher fiber content (16.1 g/100 g) compared to commercial cereals.

Table 3

Nutritional characteristics of food products used to assess the satiety index and results of this assessment.

The study revealed significant differences in satiety indexes after consumption of extrudates based on purple sweet potato with and without kidney bean and commercial cereal. The satiety index for the tested foods, in the order of commercial cereal, extruded purple sweet potato, and extruded purple sweet potato with kidney bean, were 99.29, 103.87 and 140.03, respectively (Table 3). The satiety index computed for the extruded purple sweet potato with kidney bean (E3) was significantly higher compared to that calculated for commercial cereals, indicating that the addition of kidney bean to purple sweet potato flakes resulted in a greater sense of fullness. At the determination at 180-min, the visual analogue scale (VAS) score for the sensation of fullness resulting from the consumption of extruded tuber with kidney bean was 49.84 mm (Figure 3). This score was subsequently utilized in conjunction with the regression equation derived from white bread as a reference (y = −0.30x + 87.96). Then, the calculation yielded a projected duration of 126 min for white bread to induce the same level of fullness. Consequently, it can be inferred that the consumption of extruded tuber with kidney bean led to an extended feeling of fullness by 54 min compared to the white bread.

Figure 3

The visual analogue scale (VAS) for fullness index at fasting intervals of 30, 60, 90, 120, 150, and 180 min after the consumption of extrudate made of purple sweet potato flour with and without kidney bean flour compared with commercial cereals and white bread (as reference) which showed that the consumption of extruded purple sweet potato with kidney bean substitution led to an extended feeling of fullness by 54 min compared to white bread.

The study suggests that fiber was the primary factor responsible for prolonging the feeling of satiety compared to protein, carbohydrates, lipids, and water. The fiber content showed a significant correlation with feelings of hunger (p=0.02, r=–0.30), fullness (p= 0.00, r=0.35), desire to eat (p=0.00, r=–0.40), and food intake (p=0.00, r=–0.38). Thus, consuming foods high in fiber can increase the feeling of fullness (satiety), making the extruded purple sweet potato with kidney bean a potential source of fiber to improve daily fiber intake and prevent overeating. The testing method used in this study can be applied to try other satiating foods based on total energy. However, during fasting periods after satiety testing, subjects should not be allowed to leave the area to minimize variations in physical activity and any disruptions that could affect satiety perception.

CONCLUSIONS

In conclusion, this research optimized the formula of flakes from the extrusion of purple sweet potatoes with kidney beans. The extrudate obtained on the basis of the selected formula, which replaced 40% of purple sweet potato flour with kidney bean flour, showed good sensory acceptability, nutritional value (high contents of protein and fiber), and caused a high satiety index after consumption. The estimated shelf-life of flakes was as much as 19 months. This product might provide an alternative fiber-rich food that has been proved to prolong the feeling of fullness compared to the reference and commercial food, so it is expected to prevent eating more food, which is an initial trigger for excess calorie intake. However, before mass production of this extrudate, future research is needed on its physical properties such as its wetting capacity, rehydration, milk absorption, and sedimentation. To ensure the safety of extrudates for mass production, it is also necessary to assess the content of heavy metals and microbiological tests. Furthermore, future research could investigate the long-term effects of consuming extruded purple sweet potatoes, especially as a main breakfast food, on other biological markers like blood glucose level and lipid profile.