INTRODUCTION

The most popular method to produce powder in single and quick operation is spray drying. It enables obtaining powders from aqueous solutions, suspensions or emulsions by spraying them and then evaporating the solvent from the droplets using hot air at a certain temperature and pressure. The inlet air temperature typically used in the conventional spray drying method is 160–220°C. Recently, it was presented in some published works, that the inlet air temperature can be lowered to even 75°C while reducing the humidity of the drying air [Samborska et al., 2020, 2021]. The reduction of air humidity increases the driving force of water evaporation and makes it possible to remove water at lower temperature. Such modification increases the opportunities of spray drying application for some materials of special requirements, i.e., sugar-rich and acid-rich materials, including fruit juices/concentrates/pulps or honey, characterized by low glass transition temperature (Tg) [Muzaffar et al., 2015]. The problem of drying sugar-rich materials is explained by the concept of Tg. According to this theory: 1) the product shows the greatest stability at Tg and below it, 2) there is a reduction in the stability of the food above Tg; the stability decreases with the increasing temperature difference between the temperature reached by the material during drying and its Tg [Champion et al., 2000]. At the same time, the material in the glass amorphous state can easily change into a rubbery amorphous state, when temperature increases over the material’s Tg. The rubbery amorphous state is unacceptable in spray drying – rubber sticks to the drying chamber, reduces the efficiency of the process, or even makes it impossible to obtain free-flowing powder [Barańska et al., 2021; Truong et al., 2005]. It is impossible to obtain the powder at the outlet temperature 20°C higher than Tg of the dried material [Shrestha et al., 2007], which is why it is crucial to apply dehumidified air to reduce drying temperature. Carriers’ addition can be considered as a drawback of spray drying, the application of dehumidified air affords the possibility to reduce the carrier content, which is added to increase material Tg. Typically, the powder obtained by conventional spray drying contains about 50% of carriers in solids, while dehumidified air application and low-temperature spray drying enables decreasing the carrier content even down to 10–25% [Barańska et al., 2021; Samborska et al., 2020, 2022]. Thus, the powder obtained by low-temperature spray drying with dehumidified air can be classified as “more natural”, similar in chemical composition to raw material. In our previous study, white mulberry molasses was spray dried using dehumidified air to lower drying temperature and successfully obtain a product with a carrier (nutriose) content reduced to 10% [Samborska et al., 2022]. In addition, buckwheat honey powder was produced using the same technique with a low content (25%) of the carrier (skim milk powder or maltodextrin) [Barańska et al., 2021]. So far, few studies have been published on spray drying of carrier-free powders including carrier-free powders from kiwiberry fruit pulp, durian pulp, tomato pulp, mango pulp and juçara pulp [Chin et al., 2008; Goula et al., 2004; Jedlińska et al., 2022; Pereira et al., 2020; Zotarelli et al., 2017]. Nowadays, consumers have greater nutritional knowledge and are looking for products with a short list of ingredients, without the additives [Asioli et al., 2017]. Despite the interest in producing “clean label” products, very few materials were taken into consideration while producing carrier-free powders. Thus, in this context, it seems crucial to take up the challenge of producing powders of different materials with no additional carriers, which would have satisfactory physiochemical properties.

The aim of the present study was to investigate the possibility of producing carrier-free powders of different fruit/vegetable juice/pulp/concentrate using dehumidified air-assisted spray drying and determine powder recovery and selected physical properties of the produced powders. In the case of materials for which conventional high-temperature spray-drying was possible, the physicochemical properties of the carrier-free powders obtained with both methods were compared.

MATERIALS AND METHODS

Materials

Juices and pulps were bought from the market: purple carrot juice concentrate (Maspex, Wadowice, Poland), mango puree (Purena, Złoty Potok, Poland), blackcurrant juice concentrate (Maspex, Wadowice, Poland), tomato pulp (EkoWital, Warszawa, Poland), and sauerkraut juice (Słoneczne Pole, Kalisz, Poland). Sauerkraut juice was concentrated to 27.2°Bx using a Rotavapor R-124 evaporator (BUCHI, Flawil, Switzerland). Kiwiberry (mini kiwi) pulp was prepared from the whole fruits of Weiki variety (Poland) using an NS-621CES squeezer (Kuvings, Buk-gu, Korea).

Spray drying of materials

A mobile minor laboratory spray dryer (GEA, Søborg, Denmark) was used to obtain powders of blackcurrant juice concentrate (BC), mango puree (M), purple carrot juice concentrate (PC), sauerkraut juice (S), kiwiberry pulp (KB), and tomato pulp (T). Conventional spray drying (SD) and dehumidified air-assisted spray drying (DASD) were carried out, and the variants of the produced powders are listed in Table 1. Every drying was performed in duplicate and liquid feed of 500 g was supplied each time. The parameters of the spray drying process were as follows: rotation speed 26,000 rpm; liquid feed speed 0.25 mL/s; inlet/ outlet temperature 180/80°C for SD, 80/55°C for DASD; humidity of drying air during DASD <0.5 g/m3. To conduct DASD, the spray dryer was equipped with an air dehumidification system including a TAEevo TECH020 cooling unit (MTA, Codogno, Italy) and an ML270 concentration-adsorption unit (MUNTERS, Kista, Sweden). Powder recovery (Rp) was calculated as the ratio of solids content in the obtained powder to the amount of solids in the liquid feed. Powders were put into PET/PE sealed bags and stored at a temperature of 4°C in the dark until analyzed. Analyses were done 24 h after each drying.

Table 1

Variants of powders produced using conventional spray drying (SD) and dehumidified air-assisted spray drying (DASD).

Particle morphology analysis

Particle morphology of the powders was analyzed using an XL Phenom World scanning electron microscope (SEM) (Thermo Fisher Scientific, Waltham, MA, USA) at 1,000× magnification (voltage 5 kV). Samples were prepared by placing a small amount of powder on the double sticky tape, removing the excess of the powder with compressed air, and sputtering the surface with a layer of gold by an Cressington 108auto automatic coater (EO Elektronen-Optik-Service GmbH, Dortmund, Germany).

Particle size determination

Powder particle size was determined with the laser light diffraction method conducted using a CILAS 1190 apparatus (Cilas, Orléans, France). The powder was suspended in ethanol at 10% obscuration. The results were presented as particle size distribution and cumulative particle size distribution curves, and as a median diameter (D50) derived by Size Expert software (Cilas).

Moisture content and water activity measurement

Moisture content (MC) was determined using the oven method, where 1 g of powder was dried at 104°C for 4 h [Janiszewska, 2014]. Water activity (aw) was analyzed by means of a Hygro Lab1 apparatus (Rotronic, Bassersdorf, Switzerland) at 25±1°C.

Hygroscopicity analysis

The aliquot of 1 g of each powder was incubated at 25°C and 75% relative humidity (over saturated NaCl solution) for 168 h. The hygroscopicity (H) was calculated as the amount of water absorbed per 100 g of powder solids and expressed in percentage [Samborska et al., 2020].

Bulk density and flowability analysis

A cylinder (25 mL) was filled with powder and weighed to determine loose bulk density (DL). Tapped density (DT) was determined after 100 taps by using a STAV 2003 automatic volumeter (Engelsmann AG, Ludwigshafen am Rhein, Germany). The Hausner ratio (HR) calculated according to Equation (1) was employed to express flowability [Barańska et al., 2021].

Water solubility index determination

Water solubility index (WSI) was analyzed as described by Jafari et al. [2017] with some minor modifications. An aliquot of 2 g (m0) of the sample (of known solids content, DB) was suspended in 30 mL of distilled water at ambient temperature in a centrifuge tube. The suspension was mixed for 1 min on a vortex mixer and then placed in a water bath at 37°C for 30 min. The suspension was centrifuged for 20 min at 2,054×g at ambient temperature. Supernatant (15 mL) was placed into a Petri dish of known weight and dried at 105°C for 24 h. The final mass of the residue (m1) was recorded. WSI was calculated according to Equation (2):

Color measurement

Color of the powders was measured using a CR-5 colorimeter (Konica-Minolta, Tokyo, Japan) in the CIELab color space. Lightness (L*), the contribution of red and green color (a*), and the contribution of yellow and blue color (b*) were evaluated.

Statistical methods

The results were shown as mean values with standard deviation. The analysis of variance (ANOVA) and Tukey test were performed (α=0.05) to identify the significant differences between the mean values. The Pearson correlation coefficient was determined to examine the correlations between powder parameters. Hierarchical cluster analysis (HCA) was employed to plot a dendrogram graph showing the similarities between the variants of spray dried powders. The statistical analysis was conducted using STATISTICA 13.3 software (Statsoft, Tulsa, OK, USA). All analyses were done in triplicate.

RESULTS AND DISCUSSION

Powder recovery

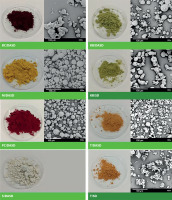

All of the powders were successfully obtained using dehumidified air as a drying medium. Their appearance immediately after drying is presented in Figure 1. It should be underlined that only two powders from kiwiberry and tomato pulps could be produced at high drying temperature without any carrier (KB/ SD, T/SD, respectively). This result corroborates the viability of dehumidified air as a drying medium in the production of “clean label” powders.

Figure 1

Carrier-free powders produced by conventional high-temperature spray drying (SD) and/or with the application of dehumidified air at low temperature (DASD) from blackcurrant juice concentrate (BC), mango puree (M), purple carrot juice concentrate (PC), sauerkraut juice (S), kiwiberry pulp (KB), and tomato pulp (T), as well as their scanning electron microscope (SEM) microphotographs (mag. 1,000×).

Powder recovery (Rp) determined for all drying variants is presented in Table 2. Laboratory and pilot scale spray drying is deemed successful when Rp exceeds 50%, while at the industrial scale its Rp should be higher than 60% to consider it as satisfactory [Bhandari et al., 1997; Wang et al., 2011]. Accordingly, the Rp of PC/DASD and BC/DASD can be classified as acceptable. However, the fact that other carrier-free powders could be produced even at low Rp, is an important progress in spray drying development of difficult sugar-rich materials. Only few studies have been published so far on spray drying of carrier-free powders. In our previous research, significantly higher Rp was determined for dried kiwiberry pulp, ranging from 75% to 93% [Jedlińska, et al., 2022]; however, it should be underlined that kiwiberry pulps were dried at different temperatures in both studies. Pereira et al. [2020] reported Rp of 66% of juçara pulp powder spray dried without a carrier. It should be emphasized that these authors determined the highest values for the powders produced with the highest carrier content (35%). In this research, a highly acceptable result (60.9%) was noted for purple carrot juice concentrate powder (PC/DASD) with no additional carrier, as a result of decreased drying temperature and stickiness, possibly due to the application of dehumidified air. Dehumidified air-assisted spray drying has also been recently applied for honey [Matwijczuk et al., 2022] and sour cherry juice concentrate [Barańska et al., 2023]. For this type of materials, it also showed significant improvement in carrier content reduction (from 50% to 30% solids) but not its complete elimination.

Kiwiberry and tomato pulps were the only materials that could be successfully dried also at higher temperature. It could result from their composition – high contents of pectin and dietary fiber that act as natural carriers [Baranowska-Wójcik & Szwajgier, 2019; Del Valle et al., 2006; Jedlińska et al., 2022]. Moreover, kiwiberry contains sucrose as a major sugar, which presents higher Tg (62°C than fructose (5°C) or glucose (31°C)) [Bhandari et al., 1997; Latocha, 2015]. These factors were probably responsible for obtaining carrier-free powders of only these two variants in the case of spray drying at high temperature. For kiwiberry pulp, the Rp of the variant spray dried with dehumidified air was significantly (p<0.05) higher than Rp obtained upon conventional drying (Table 2).

Table 2

Powder recovery (Rp), median diameter (D50), moisture content (MC), water activity (aw), hygroscopicity (H), loose bulk density (DL), tapped bulk density (DT), flowability (HR), and water solubility index (WSI) of carrier-free powders produced by conventional high temperature spray drying (SD) and/or with the application of dehumidified air at low temperature (DASD).

[i] The differences between values with the same letter (a–f) in rows were statistically not significant (p≥0.05). BC/DASD, DASD dried blackcurrant juice concentrate; M/DASD, DASD dried mango puree; PC/DASD, DASD dried purple carrot juice concentrate; S/DASD, DASD dried sauerkraut juice; KB/DASD, DASD dried kiwiberry pulp; KB/SD, SD dried kiwiberry pulp; T/DASD, DASD dried tomato pulp; T/SD, SD dried tomato pulp. S/DASD powder analysis was not possible due to the caking of powder immediately after drying.

Sauerkraut juice powder (S/DASD) was the only sample that could not be further analyzed, as it turned into rubbery state after few minutes at ambient temperature without any packaging. Such behavior of this sample was not unexpected, as sauerkraut juice has a high content of organic acids of low Tg, which poses problems with stickiness and caking [Muzaffar et al., 2015; Satora et al., 2021].

Particle morphology and size

SEM microphotographs of powders showing their particle morphology are presented in Figure 1. Powders had spherical, scattered particles, which is typical for powders after spray drying with no stickiness observed, or powders of low stickiness. However, some differences were noted in the morphology of the obtained carrier-free powders depending on raw material and drying approach followed. BC/DASD particles differed from the other variants – they were less spherical and formed some conglomerates with liquid bridges. It may be assumed that blackcurrant juice concentrate was more difficult to spray dry due to its possible stickiness. However, it was not manifested in low Rp, as it was the highest among all powders examined (Table 2). A bigger particle size could as well be responsible for this result, which in consequence enhanced cyclone recovery. Kiwiberry pulp and tomato pulp powders obtained at lower drying temperature (KB/DASD and T/DASD) had less conglomerated particles than the variants produced by high-temperature spray drying (KB/SD and T/SD) (Figure 1). This again confirms the positive impact of air dehumidification and the lowering of drying temperature to 80/50°C (inlet/outlet) on the reduction of stickiness during spray drying.

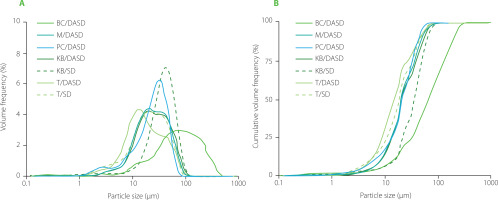

Figure 2 presents particle size distribution and cumulative particle size distribution curves of powders, while the median diameters (D50) are reported in Table 2. Most of the powders demonstrated bimodal and/or wide particle size distribution (Figure 2). This phenomenon indicates the presence of smaller, loose particles that can fill the spaces between bigger particles, which could be observed as well on SEM microphotographs (Figure 1). Blackcurrant juice concentrate powder (BC/DASD) had the widest particle size distribution and the highest D50 (Table 2). As mentioned earlier, this was the effect of stickiness during drying but was surprisingly helpful to increase Rp due to enhanced cyclone efficiency. On the contrary, KB/SD had the narrowest particle size distribution, almost no particles had diameters below 10 μm, which absence could also be observed in SEM microphotographs.

Figure 2

Particle size distribution (A) and cumulative particle size distribution (B) of carrier-free powders produced by conventional high temperature spray drying (SD) and/or with the application of dehumidified air at low temperature (DASD) fromblackcurrant juice concentrate (BC), mango puree (M), purple carrot juice concentrate (PC), sauerkraut juice (S), kiwiberry pulp (KB), and tomato pulp (T).

D50 of powder particles ranged from 14.9 to 68.0 μm (Table 2) and a significant (p<0.05) positive effect of dehumidified air application was noted for the kiwiberry pulp powders (BK/SD vs. BK/DASD). The effect of drying method of tomato pulp (T/SD vs. T/DASD) was not statistically significant (p<0.05). Zotarelli et al. [2017] spray dried conventionally mango puree without any carriers and noted D50 of 198 μm; thus, it can be concluded that dehumidified air application and decrease of drying temperature in this research affected positively the particle size of mango puree powder (M/DASD). Moreover, Jedlińska et al. [2022] described in their study properties of carrier-free powders produced from different varieties of kiwiberry and reported higher D50 values for Weiki variety powders than in the present research (111.2 and 166.8 μm, respectively). The authors produced powders at higher drying temperature (inlet 100 and 120°C); thus, the evidence from this study implies that lowering drying temperature is favorable in the case of kiwiberry pulp spray drying. Taken together, these findings confirm the role of dehumidified air in facilitating the course of drying.

Moisture content, water activity and hygroscopicity

There was a significant influence of dehumidified air application and type of material used on moisture content (MC) of the powders (Table 2). Although MC of some powders was relatively high (even above 15g /100 g), their aw was lower than 0.2. This suggests that water was bounded structurally and hence was not available for microbial growth and biochemical reactions, which points to powder’s storage stability [Shi et al., 2013]. Among T and KB powders, lower MC was noted for the variants spray dried conventionally (KB/SD and T/SD) – the rate of heat and mass transfer increased at higher temperature, and in consequence water evaporated more effectively. The lowest MC was reported for kiwiberry pulp spray dried at high temperature (KB/SD). These results are in contrast with earlier findings of Jedlińska et al. [2022], who spray dried carrier-free kiwiberry pulp, and reported much higher MC ranging from 10.3 g to 14.1 g/100 g. It may be assumed that the crust formed on the particles’ surface as a result of drying at higher temperatures and made it more difficult for water to evaporate, thus the aforementioned authors obtained higher MC values. Zotarelli et al. [2017] spray dried mango pulp powders with no carrier and noted 1.5 g/100 g of MC, which was lower that the MC determined in our study for the carrier-free mango puree powder. However, as aforementioned, this powder variant was classified as safe and stable as its MC was below 6 g/100 g. It seems likely that differences compared to the mentioned literature data were due to different drying parameters, such as drying air temperature and humidity, and different origin of mango puree. Blackcurrant juice concentrate powder (BC/DASD) had one of the highest MC values (Table 2), probably due to a high content of glucose and fructose in this raw material [Stój & Targoński, 2005]. As raw material is stickier due to high content of low-molecular-weight sugars, the drying rate decreases and thus the water content of the final product is higher [Goula & Adamopoulos, 2008]. Bhandari & Hartel [2002] reported that a high content of low-molecular-weight sugars, such as glucose and fructose, corresponded with a higher water content of sucrose powder.

Hygroscopicity (H) of the produced powders was reported in Table 2. According to the classification proposed by Dolivet et al. [2012], the powders in our study were extremely hygroscopic. This could be an effect of eliminating carrier and high sugar content of raw materials. In general, glucose and fructose have high H; thus, powders that had majority of these sugars in their composition, presented higher H values [Bhandari et al., 1997]. Sucrose is a major sugar of kiwiberries [Latocha, 2017], which could be the main reason of the lowest H values determined for KB/SD and KB/DASD among all the carrier-free powders. In the case of the mango puree powder (M/DASD), H determined in our study (Table 2) confirmed findings reported by Zotarelli et al. [2017], who spray dried mango pulp without additional carrier and obtained H= 26.9%. Both tomato pulp powders had the highest H values (Table 2), which seemed to be an effect of small particle size, which enlarged specific total surface area for moisture sorption. Finally, it should be highlighted that dehumidified air application decreased H values of the powders obtained using both methods (KB and T), which is important for their storage stability.

Bulk density and flowability

Tontul et al. [2016] analyzed tomato powders with different vegetable proteins as carriers and observed increasing bulk density (DL) with an increasing median particle size diameter. However, such a correlation was not observed in our work dealing with various powders of different origin, i.e., no significant (p≥0.05) Pearson’s correlation between D50 and DL correlation was noted (Table 3). No effect of dehumidified air application on DL was observed for tomato pulp powders (T/SD, T/DASD) (Table 2); however, the influence of drying temperature was noted in the case of kiwiberry pulp powders (KB/SD, KB/DASD). The unfavorable effect of dehumidified air application was reported, which was not expected. Higher DL favors less free spaces between particles that are filled with air, decreasing the risk of bioactive compounds degradation [García-Segovia et al., 2021]. However, it is likely that this unfavorable phenomenon was due to MC, as DL decreases with higher MC [Koç et al., 2021]. Zotarelli et al. [2017] analyzed carrier-free mango powders and determined DL equal to 0.45 g/mL; however, dehumidified air was not applied as a drying medium to lower drying temperature. In this study, the produced mango puree powder was of higher bulk density as a consequence of dehumidified air application, which enhances the powder properties. Archaina et al. [2018] produced blackcurrant juice and extract powders from processing waste at 150°C and with 40% (w/w) addition of maltodextrin as a carrier, and reported DL of 0.39 g/mL. As before, dehumidified air in this research enabled spray drying of blackcurrant juice concentrate with no additional carrier to powder with higher DL. This is beneficial because the costs of transportation, packaging, handling and storage of the powders are reduced [Koç et al., 2021].

Table 3

Pearson correlation coefficients showing a strength of correlations between physiochemical parameters and color parameters of carrier-free powders produced by conventional high temperature spray drying (SD) and/or with the application of dehumidified air at low temperature (DASD).

Geldart et al. [1984] classified powders based on the Hausner ratio (HR) as of good flowability (<1.25), average flowability (1.25–1.4) and cohesive (>1.4). The positive effect of decreased drying temperature as a consequence of dehumidified air application on HR was noted for tomato pulp powders (T/SD, T/DASD) – the variant spray dried using an innovative method had significantly (p<0.05) better flowability (Table 2). The best flowability among all tested powders was noted for the blackcurrant powder (BC/DASD), which, as described earlier, had the biggest particle size (Table 2). As was discussed, bigger particle size can imply the problematical course of drying due to stickiness, while bigger particles can at the same time promote powder recovery and flowability. This supports previous findings of Barańska et al. [2021, 2023] and Nishad et al. [2017], who observed that powders with smaller particles were more cohesive. However, the general correlation between D50 and HR determined for all powders was not significant (p≥0.05; Table 3), because other powders (M/DASD, PC/DASD, T/DASD) obtained by DASD, with significantly smaller particles, had medium flowability.

Water solubility index

Water solubility index (WSI) is an important parameter that describes powder’s behavior in water and as a consequence, determines the reconstitution properties of a final product [Jafari et al., 2017]. As consumers’ attention is focused on the dissolution of powders, it is crucial to characterize this parameter. Murali et al. [2015] spray dried purple carrot juice at 150–225°C with tapioca starch, gum Arabic and maltodextrin as carriers, and determined WSI values varying from 11.1 to 98.9%. Archaina et al. [2018] produced blackcurrant powder using spray drying at 150°C with 40% (w/w) content of maltodextrin as a carrier and reported its 94.2% solubility. Zotarelli et al. [2022] evaluated the solubility of mango pulp powders obtained at 150°C with and without maltodextrin as a carrier. They determined 77.2 and 78.6% solubility and no significant difference between the powders with and without a carrier. In the present research, similar or higher solubility was obtained for comparable raw materials at significantly lower drying temperature with no additional carrier (Table 2). This finding underlines the importance of dehumidified air application in designing “clean label” powders of high quality and satisfactory reconstitution properties. Moreover, the influence of the applied drying method was reported as well, but only for tomato powders. The variant produced at higher drying temperature had better solubility (T/SD), presumably due to MC of the analyzed samples. Lower MC of the variant spray dried at higher drying temperature (T/SD) facilitated the solubilization. A similar relationship was reported by Goula & Adamopoulos [2005], who produced tomato pulp powders as well.

The effect of the type of raw material used on WSI values was noted in the study (Table 2). According to Zotarelli et al. [2022], the presence of insoluble fiber plays an essential role in solubility of the final powder. It was confirmed by the present study results – materials that were initially in form of pulps (T and KB) had significantly (p<0.05) lower WSI values than juice concentrates (BC and PC) and clear mango puree (M).

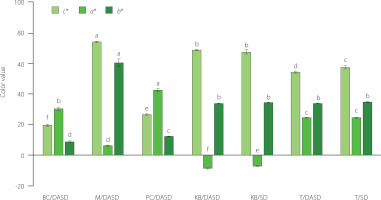

Color parameters

The results of measurements of color parameters of the carrier-free powders produced are presented in Figure 3. In general, the values differed significantly between powders because of the differences in raw materials; however, attention should be focused more on the differences between the powders made of the same materials obtained using both spray drying methods. There was no statistically significant (p≥0.05) difference in L* parameter values between KB/SD and KB/ DASD. However, the difference (p<0.05) was noted for tomato pulp powders (T/SD, T/DASD). In contrast to findings from our earlier study with sour cherry juice concentrate [Barańska et al., 2023], tomato pulp powder obtained by DASD was darker than the powder produced at high drying temperature. The values of a* parameter, which describes the contribution of red and green in the sample color, differed significantly (p<0.05) between KB/SD and KB/DASD. The favorable effect of decreased drying temperature was noted, as the contribution of green color in the DASD sample was stronger. Thus, it can be concluded that chlorophylls, which are responsible for green color of kiwiberry berries [Lawes, 1989], were better preserved in the powder produced at low drying temperature, as they are susceptible to high temperature. The differences in the values of b* parameter, that describes yellow hues in samples, were not significant (p≥0.05) for the variants spray dried using both methods; thus, the effect of lowering drying temperature on b* parameter was not observed.

Figure 3

Color parameters (L*, a*, b*) of carrier-free powders produced by conventional high temperature spray drying (SD) and/or with the application of dehumidified air at low temperature (DASD) from blackcurrant juice concentrate (BC), mango puree (M), purple carrot juice concentrate (PC), sauerkraut juice (S), kiwiberry pulp (KB), and tomato pulp (T). The differences between mean values marked with the same letter (a–f) for each parameter separately were statistically not significant (p≥0.05).

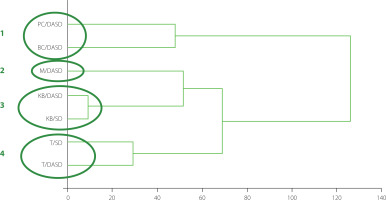

Hierarchical cluster analysis

HCA analysis enables presenting results in the form of a dendrogram that shows the hierarchy, organization and similarity of tested variants [Granato et al., 2018; Senior et al., 2012]. The dendrogram displays the horizontal axis representing the distance, thus the similarity between clusters. Four clusters were formed: first cluster of PC/DASD and BC/DASD, second cluster with single M/DASD, third with KB/DASD and KB/SD, and fourth cluster with T/DASD and T/SD (Figure 4). The strongest similarity was observed for the variants in cluster 3, as the distance was only 8. The effect of the type of raw material used was more evident than that of the drying method applied, as the distance between variants spray dried using both methods were small, indicating strong similarities.

Figure 4

Dendrogram plot derived from hierarchical cluster analysis (HCA) for physiochemical and color parameters of carrier-free powders produced by conventional high temperature spray drying (SD) and/or with the application of dehumidified air at low temperature (DASD) from blackcurrant juice concentrate (BC), mango puree (M), purple carrot juice concentrate (PC), sauerkraut juice (S), kiwiberry pulp (KB), and tomato pulp (T).

CONCLUSIONS

Food products with a short list of ingredients have spurred a growing interest among consumers whose awareness on food formulation has substantially increased over the past decade. Dehumidified air application to produce powders by spray drying enables not only decreasing carrier content, but also eliminating it entirely in some types of raw materials. This study has investigated the possibility of producing carrier-free powders from sauerkraut juice, purple carrot juice concentrate, mango puree, blackcurrant juice concentrate, kiwiberry pulp, and tomato pulp using high temperature – conventional spray drying and low temperature – dehumidified air-assisted spray drying. Decreasing drying temperature as a consequence of low drying air humidity was the only possible solution to produce carrier-free powders of sauerkraut juice, purple carrot juice concentrate, mango puree, and blackcurrant juice concentrate. Moreover, considering process performance, the satisfactory powder recovery (over 60%) was noted in the case of two variants: purple carrot juice concentrate and blackcurrant juice concentrate. For kiwiberry and tomato pulps that were spray dried using both methods, some of the physiochemical properties were enhanced when the dehumidified air was applied. Median particle size diameter, that indicates the ease of the course of drying, was favorably smaller, hygroscopicity was reported to decrease and flowability was improved when the inlet drying temperature was lower (flowability only for tomato pulp powders). Taken together, the differences between the variants spray dried with both methods were minor; however, selected properties of the powders produced using dehumidified air were more beneficial than these of the powders dried conventionally.

This research provided results demonstrating that lowering drying air humidity is a vital factor in designing powders of carrier-free juice/concentrate/pulp. Dehumidified air application enables lowering drying temperature, which consequently decreases the risk of stickiness and problems during drying, allowing the successful production of powders. The approach presented in this study has the potential to be applied in the formulation and production of clean label powders, meeting expectations of modern consumers.