INTRODUCTION

Modern consumers are increasingly aware of the nutritional value and health benefits of food products. New consumer behavior trends have decreased the interest in intensive farming crops and increased the demand for alternative crop species, including minor cereals such as hulled wheats [Boukid et al., 2018]. Spelt (Triticum spelta L.) is the most popular species in this group of cereals. Spelt grain has a high nutritional value, and it is a rich source of bioactive compounds and essential micronutrients [Arzani & Ashraf, 2017; Shewry & Hey, 2015; Suchowilska et al., 2012]. Although there are known studies suggesting that spelt delivers exceptional health benefits [Valli et al., 2018; Wang et al., 2020], according to some authors there is insufficient evidence to confirm this claim [Dinu et al., 2018; Shewry, 2018]. The nutritional value of high-yielding bread wheat (Triticum aestivum L.) varieties was not affected by intensive farming practices [Shewry et al., 2020], but the content of essential nutrients, in particular Fe, Zn, and Mg, continues to decrease in wheat grain [Fan et al., 2008]. In general, spelt is not well suited for intensive agriculture, and high rates of nitrogen fertilization compromise the quality of spelt grain [Sugár et al., 2019]. Spelt does not require intensive chemical protection, which decreases the cost of agricultural treatments and increases spelt’s suitability for organic farming. The main challenges in the production and processing of spelt are low genetic yield potential, considerable susceptibility to lodging, and non-threshability [Packa et al., 2015; Rapp et al., 2017].

The technological suitability of wheat grain is determined mainly by its milling quality and the baking quality of flour. Flour yield is influenced by kernel size and the proportion of the seed coat in kernel mass, whereas the baking quality of flour is a complex trait that is determined by the quantity and quality of protein, including gluten, dough strength, α-amylase activity, and the degree of starch damage [Carson & Edwards, 2009]. Spelt grain is generally more abundant in protein than bread wheat grain, but the values of grain quality parameters, including gluten weakening, dough strength and stability, are usually lower in spelt [Rodríguez-Quijano et al., 2019; Tóth et al., 2022].

Bread wheat and spelt are allohexaploid species possessing the same AABBDD genomes [Dvorak et al., 2012]. Considerable genetic similarities of both cereals promote introgression and the production of breeding lines that could combine the desirable traits of bread wheat with the high nutritional value of spelt [Gulyás et al., 2012]. Therefore, the genetic potential of T. aestivum could be harnessed to develop new spelt varieties with high yield potential and resistance to lodging. Modern spelt cultivars are characterized by very high yield potential, satisfactory resistance to lodging, and less compact glumes than “true spelt”, which facilitates dehulling [Dinkel, 2023; Winterspelz, Winterdinkel: Sorte Divimar, 2023]. However, information about the genetic origin of new spelt cultivars and the proportion of T. aestivum genes is rarely available. The phenotype of such spelt is similar to that of bread wheat, in particular as regards spike traits, plant height, and stalk rigidity. Despite the fact that modern spelt cultivars are not recognized as “true spelt” by some consumers and agricultural producers, especially organic farmers, the technological quality of grain and flour does not differ from that of traditional varieties, and the obtained bread receives high or very high scores in sensory analyses [Wiwart et al., 2017].

Due to the high nutritional value of grain, relatively low soil requirements, and considerable resistance to fungal pathogens, T. spelta is highly suited for genetic recombination with bread wheat cultivars grown in intensive farming systems [Chrpová et al., 2021; Rachoń et al., 2020; Sugár et al., 2019]. Breeding efforts aiming to produce hybrids between bread wheat and spelt are justified by the following observations: (1) sustainable farming practices should be incorporated in modern agricultural systems; (2) wheat is the most important small-grain cereal for human consumption; (3) agricultural production should be profitable and socially acceptable. The grain of the developed hybrids should be characterized by high technological quality and should be suitable for bread making. However, these parameters have not yet been more extensively studied in hybrids between bread wheat and spelt and literature data are only fragmentary and scarce [Ceglińska, 2003].

Therefore, the aim of this study was to determine differences in the processing suitability of grain in breeding lines derived from single-cross hybrids between T. spelta and T. aestivum. The content of basic nutrients in grain, milling quality of grain, rheological properties of dough, and bread quality were evaluated.

MATERIALS AND METHODS

Material

The experimental material comprised the grain of 36 spring breeding lines derived from single-cross hybrids between three bread wheat (T. aestivum L.) cultivars grown in an intensive farming system and five spelt (T. spelta L.) breeding lines, as well as the grain of the parental lines (Table 1).

Table 1

Breeding lines and their parental components examined in the study. The origin of the lines is given in brackets.

| Parental spelt line/ bread wheat cultivar | Breeding line (♀×♂) | Breeding line (♀×♂) | Breeding line (♀×♂) | ||||

|---|---|---|---|---|---|---|---|

| No | No | Origin | No | Origin | No | Origin | |

| 1 | S10 | 9 | (T×S10) | 21 | (Z×S13)I | 33 | (S13×T)II |

| 2 | S11 | 10 | (K×S10) | 22 | (Z×S13)II | 34 | (S13×T)III |

| 3 | S12 | 11 | (K×S11) | 23 | (Z×S13)III | 35 | (S14×T) |

| 4 | S13 | 12 | (K×S11)I | 24 | (Z×S13)IV | 36 | (S10×K) |

| 5 | S14 | 13 | (K×S12) | 25 | (Z×S13)V | 37 | (S10×K)I |

| 6 | cv. Torka (T) | 14 | (K×S12)I | 26 | (Z×S13)VI | 38 | (S11×K) |

| 7 | cv. Zebra (Z) | 15 | (K×S12)II | 27 | (Z×S13)VII | 39 | (S12×T) |

| 8 | cv. Kontesa (K) | 16 | (K×S14) | 28 | (S10×T) | 40 | (S12×K)I |

| 17 | (Z×S10) | 29 | (S11×T) | 41 | (S13×T) | ||

| 18 | (Z×S11) | 30 | (S11×T)I | 42 | (S14×K) | ||

| 19 | (Z×S11)I | 31 | (S13×T)I | 43 | (S14×K)I | ||

| 20 | (Z×S13) | 32 | (S13×T)I | 44 | (S14×K)II | ||

Field experiment

The breeding lines of spring spelt (S10, S11, S12, S13 and S14) were selected at the Department of Genetics, Plant Breeding and Bioresource Engineering of the University of Warmia and Mazury in Olsztyn (Poland) from the accessions derived from the Polish Genebank (NCPGR) of the National Center for Plant Genetic Resources (Radzików, Poland). The analyzed parental lines fully meet “true spelt” criteria in terms of phenotypic and agronomic traits. Torka and Zebra are elite bread wheat cultivars (E) with the highest flour strength and high protein content, whereas Kontesa is a high-yielding variety of quality class A [Gacek, 2013]. The field experiment was performed at the Agricultural Experiment Station in Bałcyny in Poland (53°36’ N latitude; 19°5’ E longitude). Spikelets (spelt and breeding lines) or seeds (bread wheat) were sown in duplicate at a density of 200 spikelets/m2 (spelt and breeding lines) and 400 seeds/m2 in plots with an area of 9 m2 each. The plots were fertilized with N/P/K at 80/25/80 kg/ha. Chemical plant protection was not applied. Grain (bread wheat) and spikelets (spelt and hybrids) were harvested in the over-ripe stage (BBCH 92) [Witzenberger et al., 1989] with a Wintersteiger Classic (Ried im Innkreis, Austria) plot harvester. After harvesting, the yield and grain quality parameters listed in the next subsection were determined.

Grain milling

At least 2 kg of grain was harvested from the three wheat cultivars, five spelt breeding lines and most productive 17 hybrid lines for the assessment of grain baking properties. The milling quality of grain samples was evaluated before milling by determining grain weight [ISO 7971-3:2019], vitreousness using Pohl farinator for cutting grains (Bipea method Ref. 204-1104), and thousand kernel weight [ISO 520:2010]. Grain samples were cleaned and tempered to a moisture content of 16 g/100 g by adding water. Grain was conditioned for at least 24±1 h to promote rapid and complete separation of the endosperm. The samples were milled in a Bühler MLU-202 pneumatic laboratory mill (Bühler, Uzwil, Switzerland). Six flour streams were combined to obtain straight-grade white flour for quality analysis and baking trials. The flour yield (66.4% to 75.8%) and ash content [ISO 2171:2007] of each grain sample were determined. The flour yield was calculated as the total flour obtained in the laboratory milling to all milling products including bran.

Analysis of the baking quality of flour

The bread-making potential of the flour samples was evaluated by examining the protein and starch complex. The protein complex was analyzed by determining protein content [ISO 20483:2013] using Kjeltec 2200 (Foss, Hilleroed, Denmark), gluten content, gluten index (GI) [ISO 21415-2:2015] using Glutomatic 2200 (PerkinElmer, Inc., Waltham, Ma, USA), and the Zeleny sedimentation index [ISO 5529:2007]. The starch complex was evaluated by determining the falling number [ISO 3093:2010] using Perten Falling Number® system (FN 1500 model, PerkinElmer) and starch damage [ISO 17715:2013] using SDmatic (KPM Analytics, Villeneuve-la-Garenne, France). The moisture content of flour was measured according to ISO standard [ISO 712:2009].

Analysis of the rheological properties of dough

The rheological properties of wholemeal flour and refined flour dough were analyzed in the Chopin Mixolab system (KPM Analytics) according to the procedure described by Suchowilska et al. [2019]. The Mixolab test was performed with the application of a standard Chopin+ protocol: dough weight – 75 g, kneading speed – 80 rpm, water temperature – 30°C and the following settings of the time and temperature in the phases of analyses: 8 min at 30°C, heating at 4°C/min for 15 min, holding at 90°C for 7 min, cooling to 50°C at 4°C/min for 10 min, and holding at 50°C for 5 min. Water absorption was expressed as the volume of water required to obtain dough with a consistency of 1.10 N×m (±0.05) at point C1 in the first test phase. The following protein characteristics of the tested flours were read from the Mixolab curve: dough development time (T1, min), stability time (min); C2, C10, C12, C14, C16, C18, C1-2, Cs (protein weakening, decrease in consistency due to mechanical shear stress in dough, followed by temperature increase; measured 10, 12, 14, 16 and 18 min after the beginning of the test, the calculated difference between points C1 and C2, N×m, and the stability measured 8 min after the test started), and slope α (indicator of protein weakening, N×m/min). The starch complex was analyzed based on the following Mixolab parameters: C3, C3-C2 (starch gelatinization, N×m); C4, C3-C4 (amylolytic activity, N×m), C5, C5-C4 (starch retrogradation, N×m), D2 and D3 (initial and final temperature of starch gelatinization, respectively, °C), time T2, T3, T4, T5 (respectively: initial and final time of starch gelatinization, time of dropping the consistency in point C4 during cooling process of a dough, final time of analysis, min), and slopes β and γ (starching speed and enzymatic degradation, respectively, N×m/min). D1, D4 and D5 (°C, correspond to an estimation of dough temperatures at test point characteristics: C1, C4 and C5, respectively). Six qualitative indices, including water absorption (WA), mixing (MIX), gluten+ (GLU+), viscosity (VIS), amylase activity (AMY) and starch retrogradation (RET), were converted from standard curve parameters and analyzed using the Chopin Profiler protocol. The results were expressed as the ratio of the values for the sample and the standard. All parameters were analyzed in duplicate.

Baking trials

Dough was prepared in a standard baking test with the use of the one-step method [Suchowilska et al., 2019; Wiwart et al., 2017]. Flour (600 g) was combined with water, compressed yeast (18 g), and salt (9 g) at 28–30°C in a laboratory mixer (KitchenAid, Benton Harbor, MI, USA). The moisture content [ISO 712:2009] of flour was determined to adjust flour weight to a moisture content of 14 g/100 g. Water was added in an amount required to achieve the water absorption capacity indicated in the Mixolab system (KPM Analytics), and it was increased by 3 g/100 g until dough consistency reached 350 Brabender units (BU). Dough was fermented for 60 min in a laboratory proving cabinet at 30°C and 75% relative humidity (RH). After 30 min, dough was kneaded by hand for 60 s and divided into three portions of 250 g each. Each portion was rounded, placed in a baking tin, and kept in a laboratory proving cabinet at 30°C and 75% RH for the time required for optimal dough development (34–44 min). Loaves were baked at 230°C for 30 min in an oven (Piccolo Wachtel Winkler, Pulsnitz, Germany) (live steam was injected immediately after the loaves were placed in the oven). Baked loaves were brushed with water and stored in sealed plastic containers to prevent desiccation. After 24 h of cooling, each sample was weighed and analyzed for porosity, crumb elasticity, and specific volume with the rapeseed displacement method [Różyło et al., 2015] (expressed in mL per 100 g of bread). Crumb hardness (expressed in newtons, N), namely the maximum force needed to achieve 50% deformation of a 3-cm-thick slice, was determined in five replicates with the Instron 1140 universal testing machine (Norwood, MA, USA). A probe with a diameter of 35 mm was used in the test, and crosshead speed was 50 mm/min. Crumb and crust color was determined in five replicates with a Minolta CR-310 colorimeter (Konica Minolta Sensing Americas, Inc, Ramsey, NJ, USA). The measurements were performed in the CIELab system (L* – lightness, a* –green-red coordinate, b* –blue-yellow coordinate).

Statistical analysis

Statistical analyses were performed using the Statistica 13 program [TIBCO Software Inc., 2017]. After testing the condition of normality of distribution, the results were processed by analysis of variance (ANOVA), and the significance of differences between mean values was determined by the multiple Student-Newman-Keuls (SNK) test. Furthermore, the results were subjected to multivariate analyses (principal component analysis – PCA and hierarchical analysis). The non-parametric Kruskal-Wallis test was used to compare mean values of Mixolab indices.

RESULTS AND DISCUSSION

Grain yield and grain quality parameters

The grain yield and grain quality parameters of the analyzed hybrid lines and parental lines are presented in Table 2. As expected, grain yield was significantly highest in bread wheat (6.64 t/ha), and the grain yield of hybrid lines was higher in comparison with spelt (5.43 vs. 4.97 t/ha) but the difference was not statistically significant. No significant differences in grain yield were observed between hybrid lines. The content of protein and gluten in the grain of hybrid lines (15.2 g/100 g dry matter, d.m. and 34.0 g/100 g, respectively) assumed intermediate values between bread wheat (13.1 g/100 g d.m. and 27.5 g/100 g, respectively) and spelt (17.1 g/100 g d.m. and 36.1 g/100 g, respectively). The grain of hybrid lines where spelt was the maternal component was characterized by significantly higher protein and gluten content than the grain of hybrid lines where spelt was the paternal component. The starch content of hybrid grain (64.8 g/100 g d.m.) did not differ significantly from that noted in bread wheat (67.8 g/100 g d.m.) and spelt (62.1 g/100 g d.m.) grain, but the analyzed hybrids were characterized by significantly higher grain filling (average test weight of 79.5 kg/hL vs. 75.0 kg/hL in spelt) and relatively high thousand kernel weight. It should also be noted that the Zeleny index was significantly higher in hybrid lines than in bread wheat (62 mL vs. 45 mL), and the average values of this parameter were higher in hybrid lines where spelt was the maternal component than in hybrid lines where bread wheat was the maternal component (65 mL vs. 54 mL).

Table 2

Grain yield and basic parameters describing the technological quality of the grain of hybrid lines and their parental lines.

[i] TKW, one thousand kernel weight; d.m., dry matter; RDS, relative standard deviation. Values followed by the different letters (a–c) within the column differ significantly at p<0.05 (for spelt, bread wheat and hybrids). Values with different letters x and y for S×W and W×S hybrids differ significantly at p<0.05.

Dietary recommendations, current food trends, and the growing interest in new crops among farmers contribute to increasing the area under cereals characterized by high yields, satisfactory technological quality, and high nutritional value. These traits have been relatively well researched in spelt [Biel et al., 2021; Bonafaccia et al., 2000]. The present study was undertaken to examine unique hybrid lines between bread wheat and spelt which combine the attributes of their parental forms: high yield and resistance to lodging (bread wheat) and high processing suitability and resistance to fungal pathogens (spelt).

Technological quality of flour and rheological properties of dough

The mean values of the main parameters describing the technological quality of the tested flours of spelt, wheat and hybrids are presented in Table 3 and the values for flours of individual lines are shown in Table S1. Spelt flours were characterized by significantly highest protein (15.9 g/100 g d.m.) and gluten (45.4 g/100 g) content, but also the lowest quality (gluten index – 43). Bread wheat flours were characterized by the lowest protein (12.1 g/100 g d.m.) and lowest gluten content (28.6 g/100 g), as well as the highest gluten quality (gluten index – 85). Hybrid lines were characterized by a relatively high content of protein (13.2 g/100 g d.m.) of high quality (gluten index – 77). However, no significant differences were noted between the tested hybrids (W×S and S×W). The ash content of the examined flours ranged from 0.51 (S12×Kontesa) to 0.74 g/100 g d.m. (S11). Spelt flours had significantly higher ash content than bread wheat and hybrid flours. Significant differences were also observed between hybrid lines of different origin: ash content was significantly lower (more desirable) in S×W than W×S hybrids. Starch damage values ranged from 14.4 (S10×Torka) to 24.8 UCD (Zebra×S13) and were influenced by the origin of grain. On average, starch damage values were significantly lowest (17.5 UCD) in spelt flours and highest in bread wheat flours (23.0 UCD). Wheat flours were characterized by low α-amylase activity, as evidenced by falling number values above 250 s (338.5 to 365.5 s). Moderate α-amylase activity was noted in only one flour sample derived from Zebra as the maternal line (falling number – 162.5 s).

Table 3

Mean values, relative standard deviation (RSD), and range (min÷max) of basic parameters describing the technological quality of flour from the grain of single-cross hybrids between bread wheat and spelt, and their parental lines.

Dough torque at point C3 on the Mixolab curve (2.17 N×m on average) was highest in hybrid lines derived from spelt maternal lines and bread wheat cv. Torka as the paternal component (Table S1). The lowest torque at point C3 (1.86 N×m on average) was noted in hybrids derived from cv. Kontesa as the maternal component. In turn, parameters C4 and C5 were lowest in hybrids derived from cv. Zebra as the maternal component (1.53 and 2.54 N×m on average, respectively) and highest in hybrids derived from cv. Torka as the paternal line (1.83 and 3.14 N×m on average, respectively). The initial (D2) and final (D3) temperatures of starch gelatinization were determined at 48.2–52.8°C and 70.0–84.2°C, respectively. The value of slope β, describing the starch pasting rate, ranged from 0.083 to 1.002 N×m/min, and no significant differences in this parameter were found between grain types. Starch damage had no significant effect on slope β, or on initial (D2) and final (D3) temperature of gelatinization. However, greater differences between points C1 and C2, and between points C3 and C2 were observed with an increase in starch damage.

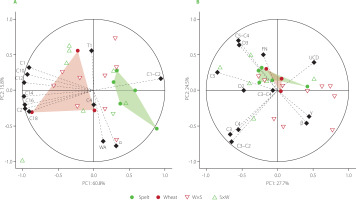

The PCA results for 12 protein parameters and 12 starch parameters are presented in Figure 1. Protein parameters had greater discriminatory power because PC1 and PC2 explained 76.6% of total variance, whereas starch parameters explained only 52.2% of total variance. Eight protein parameters (C1, C2, C10, C12, C14, C16 C18, and C1-C2) were highly correlated with both PCs, as demonstrated by the location of the corresponding points in the vicinity of the circle with a radius of 1, which corresponded to the absolute value of the correlation coefficient r. Point C4 was positioned near the beginning of the coordinate system, which indicates that this parameter had the smallest discriminatory power. The areas corresponding to three bread wheat cultivars and five spelt lines are completely separate, and the distribution of parental components in hybrid lines (W×S and S×W) had no significant effect on their similarity to spelt or bread wheat.

Figure 1

PCA biplot of the parameters associated with protein (A) and starch (B) quality in the grain of five spelt breeding lines, three bread wheat cultivars, and 17 single-cross hybrids between bread wheat × spelt (W×S) and spelt x bread wheat (S×W). C1, C2, C3, C4, C4, C5, C10, C12, C14, C16, C18, dough resistance (N×m) measured at point C1, C2, C3, C4 and C5, and after 10, 12 … 18 min of the analysis; T1, dough development time (min); D2 and D3, initial and final temperature of starch gelatinization (°C); WA, water absorption; FN, falling number (s); UCD, starch damage in UCD units; α, protein weakening (N×m/min); β and γ, starching speed and enzymatic degradation, respectively (N×m/min). The results were obtained in the Mixolab system (Chopin Technologies, France).

The Mixolab profiler indices for the grain and flour of hybrid lines and their parental forms are presented in Table 4. In the grain analysis, water absorption capacity was characterized by the smallest variation and the highest similarity to the reference wheat cultivars and spelt lines. In the flour analysis, the same observations were made for viscosity. Grain milling significantly affected flour quality due to differences in starch damage values. The Mixolab profiles for wheat cultivars and spelt lines did not differ significantly, but retrogradation values were higher and gluten+ values were lower in spelt.

Table 4

Mean values of Mixolab Profiler indices, relative standard deviation (RSD,%), range (min÷max), the values of test function H for Kruskall-Wallis test and probabilities associated with H for grain and flour of studied cereals.

The study demonstrated that bread wheat flours are characterized by the lowest protein and gluten content and the highest gluten quality, and it confirms previous observations made by Ceglińska [2003], Geisslitz et al. [2019], and Takač et al. [2021]. However, in the works of Ceglińska [2003] and Packa et al. [2019], flours obtained from hybrid lines inherited desirable traits from parental lines, including high protein content (spelt) and high gluten quality (bread wheat). Considerable variations in the protein and gluten content of hybrid lines were also reported by Diordiieva et al. [2018], and they suggest that effective selection for high content of both protein and gluten is possible. Average gluten content was nearly 25% lower in hybrids than in spelt, but the grain of hybrid lines was characterized by much higher gluten quality, as evidenced by the fact that gluten index values were 33 units higher on average in hybrids. Hybrid lines were highly similar to the studied bread wheat cultivars in terms of gluten content and quality, and their baking quality was higher in comparison with spelt. In the works of Tran et al. [2020] and Tóth et al. [2022], the gluten index was significantly lower in spelt than in bread wheat. Geisslitz et al. [2019] examined 75 genotypes of four Triticum species (T. aestivum, T. spelta, T. dicoccon, and T. monococcum) and found that the gliadin/glutenin ratio was more than 30% higher (3.3 vs. 2.5) in spelt gluten than in bread wheat gluten. Glutenins are good predictors of bread volume. In the current study, the total protein content of hybrid lines was significantly lower than in spelt (by approx. 20%), but it was around 9% higher than in bread wheat.

Starch damage is considered to be one of the most important criteria for assessing the baking quality of flour. This parameter affects the water absorption capacity of flour, the rheological properties of dough, dough fermentation, and crumb structure [León et al., 2006; Litvyak, 2018]. In the present study, starch damage ranged from 14.4 (10×Torka) to 24.8 UCD (Zebra×13), and it was influenced by the origin of milled grain. Considerable variations in the starch damage values of the examined hybrids (14.4–24.8 UCD) indicate that these lines can be used in the production of a wide assortment of baked goods. Wheat flours intended for the production of bread and confectionery goods are generally characterized by a wide range of starch damage values, from 14 to 24 UCD [Liu et al., 2018]. In a study by Dąbkowska [2009], starch damage values ranged from 13.9 to 17.7 UCD in spelt flour, and were determined at 19.3 UCD on average in bread wheat flour. According to Krawczyk et al. [2008], starch damage values are generally low in spelt flour (17.5 UCD). Wilson et al. [2008] reported lower starch damage values in spelt flour than in control wheat flour, and attributed these differences to the soft endosperm of spelt grain. Tóth et al. [2022] observed that variations in starch damage values were determined in 40.5% by genotype, and were significantly influenced by the interaction effects of genotype×environment (51.9%).

Flour ash content is a crucial parameter in the evaluation of grain milling characteristics. The milling efficiency index (MEI), which is defined as the ratio of total flour yield to flour ash content, is one of the most reliable indicators of milling quality. The higher the value of MEI, the higher the milling quality of wheat grain [Dziki et al., 2017]. High ash content of grain is not a desirable parameter because it decreases flour yield and reduces milling profits. However, ash content is a desirable trait from the nutritional point of view because it denotes high mineral content. In the present study, spelt flours were characterized by significantly highest ash content. In this respect, the examined hybrids were more similar to bread wheat than spelt, which implies that they have superior milling characteristics in comparison with T. spelta.

The water absorption capacity of wheat flour is influenced by several factors, mostly kernel size, grain hardness, starch damage, protein content, as well as the content and proportions of pentosans and arabinoxylans (AX) [Sapirstein et al., 2018]. The water absorption capacity of gluten proteins is determined by their quality, and it generally ranges from 250 to 354% [Kaushik et al., 2015]. In turn, the water absorption capacity of starch is affected by the degree of starch damage: whole grains retain around 40% of water on the surface (relative to their own weight), whereas damaged starch absorbs up to 300% of water [Jukić et al., 2019; Sen et al., 2016]. In the present study, higher starch damage values were significantly correlated (r=0.497, p<0.05) with increased water absorption capacity in all flours, and the strongest correlations were observed in the flours obtained from the grain of the examined hybrid lines (r=0.823, p<0.01).

The rheological properties of dough measured in the Mixolab system provide information about starch pasting properties, stability of the starch gel when heated, and starch retrogradation (torque at points C3, C4 and C5, respectively) [Banu et al., 2011; Haros et al., 2006; Kahraman et al., 2008]. Dough torque at point C3 depends on slope β, i.e., the rate of changes in starch pasting properties. High torque value at point C3 points to high dough flexibility and is characteristic of the flour fraction originating from the central part of the endosperm [Banu et al., 2011; Mixolab Application Handbook 2012]. The discussed parameters were influenced by grain type, but no significant differences were found. Dough torque ranged from 1.61 to 2.68 N×m at point C3, from 1.07 to 2.52 N×m at point C4, and from 1.66 to 3.34 N×m at point C5. The mean values for bread wheat and spelt samples were higher than those noted in our previous study [Szafrańska et al., 2015], which could be attributed to low α-amylase activity of the examined grain samples. Similarly to our study, no significant differences were found between bread wheat and spelt [Szafrańska et al., 2015]. However, in the work of Zhygunov et al. [2020], spelt flours differed significantly in amylolytic activity and hot gel stability. Spelt flours had higher C4 values, and the difference between C3 and C4 was very small, which points to high thermal stability of starch gel. Wheat flours with lower amylolytic activity were characterized by higher starch damage values because hot dough continues to liquefy, which explains the high difference between C4 and C3. In a study by Dąbkowska [2009], flours obtained from different types of grain differed in initial starch gelatinization temperature determined with an amylograph. Initial starch gelatinization temperature was determined at 50.1–60.6°C in refined spelt flours and at 56.9–64°C in bread wheat flour, whereas the final temperature of gelatinization was determined at 65.9–90.8°C and 68.9–82.8°C, respectively. In the current study, the initial and final temperature of gelatinization was determined in the range of 48.2–52.8°C and 70.0–84.2°C, respectively.

The Profiler has been developed specifically to control quality and simplify the reading of data from Mixolab tests. This solution is not strictly a research tool, nor a tool for correcting potential flour defects, but it is a unique “translator” that converts complex technological data into six simple quality indicators [Dubat & Bock, 2018]. The Profiler is a highly convenient solution that facilitates the selection of the most desirable traits in quality breeding [Suchowilska et al., 2019]. The hybrid lines evaluated in this study were characterized by considerable variations in all six quality indicators, which indicates that lines characterized by high technological quality can be selected and that bread wheat and spelt hybrids can be crossed to obtain varieties with high baking quality of flour.

Laboratory baking test

Cross-sectional images of bread made from the grain of bread wheat cultivars, spelt lines, and 15 single-cross hybrids between bread wheat and spelt are presented in Figure 2. The breads baked in laboratory trials were well risen, and they were characterized by desirable crust color and relatively even crumb porosity. Despite some variability between all tested materials in terms of color of crust, the differences proved to be statistically insignificant. The flours obtained from hybrid lines where elite bread wheat cv. Zebra was the maternal component were characterized by the highest baking quality (Table S1). Bread loaves baked from these flours had the largest average volume and lowest crumb hardness (Figure 3). Despite their low average gluten content, these flours were characterized by high values of the gluten index, water absorption, and dough stability time. High starch damage values and the highest proportion of particles smaller than 95 μm directly contributed to the high water absorption capacity of these flours. The resulting dough also had superior mechanical properties during processing in the dough rounder.

Figure 2

Cross-sectional images of bread loaves baked in laboratory trials from the flour of bread wheat cultivars (A–C) and spelt lines (D–H) as the parental components of single-cross hybrids (I–W). A, B, C, bread wheat cvs. Torka, Zebra, and Kontesa, respectively; D…H, spelt lines S10, S11, S12, S13, and S14; I, Kontesa ×10; J, 10×Kontesa; K, Kontesa×11; L, Kontesa ×11; M, (Kontesa ×14)’; N, Zebra×11; O, Zebra×13; P, (Zebra×13)′; Q, (Zebra×13)″; R, (Zebra×13)′″; S, 10×Torka; T, 11×Torka; U, 13×Torka; V, 12×Kontesa; W, 13×Kontesa.

Figure 3

Dough yield (A), bread yield (B), 100 g bread volume (C), and bread crumb hardness (D) for for the hybrids and their parental lines: bread wheat, W (1), spelt, S (2), W×S hybrid lines (3), S×W hybrid lines (4).

Four bread parameters for the 15 analyzed hybrids and their parental lines are presented in Figure 3. Significant differences were observed in bread yield and 100 g bread volume, whereas dough yield and bread crumb hardness did not differ significantly between the analyzed hybrids and their parental lines. Bread volume was lower for hybrid lines (318.3 mL on average) than for spelt (346.5 mL on average) and bread wheat (377.8 mL on average), but the obtained loaves were consistent with Polish quality standards regarding the minimum volume of bread loaves (200 mL) baked from type 750 wheat flour [PN-A-74105:1992]. Hybrid lines differed significantly from bread wheat in terms of bread yield (140.6 and 141.6 vs. 136.4%), but no significant differences in bread yield were found between hybrid lines and spelt (139.0%). Despite the absence of significant differences in crumb hardness, the average values of this parameter were higher in hybrid lines, in particular when spelt was the maternal component, than their parental lines (Figure 3).

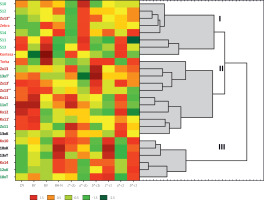

The hierarchical cluster analysis of 10 bread parameters in 15 hybrid lines and their parental lines supported the discrimination of the examined cereals (Figure 4). The studied lines and cultivars were grouped in three clusters. The first cluster (I) comprised all spelt parental lines, bread wheat cvs. Kontesa and Zebra, and one hybrid line where bread wheat cv. Zebra was the maternal component. The second (II) and largest cluster consisted of 10 hybrid lines and bread wheat cv. Torka. The third cluster (III) contained six hybrid lines. Cluster I was characterized by high values of a* for bread crumb and low values of bread yield and L for bread crumb; cluster II was characterized by high values of dough yield and bread yield, and low values of L* for bread crust and b* for bread crust; and cluster III was characterized by high values of bread crumb hardness, L* for bread crust, and b* for bread crust, and low values of dough yield, bread volume, and a* for bread crumb. The above values had a high discriminatory power. It should also be noted that spelt was the maternal component in only three of the 10 hybrid lines in cluster II (33.3%).

Figure 4

The results of the hierarchical cluster analysis of 10 bread parameters in 15 hybrid lines and their parental lines. DY, dough yield; BY, bread yield; BV, bread volume; BH-N, bread crumb hardness; L*, a*, b*, color parameters of bread crumb (cb) and crust (ct): lightness (L*), green-red coordinate (a*), blue-yellow coordinate (b*); I, II, III, cluster numbers.

The baking quality of flour can be directly and reliably evaluated in baking trials. Baking trials were conducted for 17 hybrid lines and eight parental lines. The lines were selected for the test based on the results of previous rheological analyses. Bread loaves baked from spelt flour were characterized by the least desirable cross-sections. In contrast, loaves made from bread wheat flour were well-risen, had a visibly rounded top and desirable crumb structure. Bread loaves made from the flour of hybrid grain were more similar to the loaves baked from bread wheat flour than spelt flour, which suggests that bread wheat genes significantly improve the baking quality of spelt flour. However, there is no conclusive evidence to support the above claim. Some authors found that the rheological properties and baking quality of spelt flour were similar or higher in comparison with bread wheat flour [Rodríguez-Quijano, 2019; Sobczyk et al., 2017], whereas other researchers reported contrary results [Frakolaki et al., 2018]. These discrepancies could be attributed to differences in the experimental materials, environmental conditions, and farming systems. Similarly to bread wheat, spelt is a self-pollinating species that responds strongly to environmental variation. The flour of modern spelt cultivars harboring T. aestivum genes and designed for intensive cultivation is characterized by high baking quality [Wiwart et al., 2017], and introgressive hybridization cannot be avoided in modern agriculture. Therefore, the proportion of T. aestivum genes can be expected to increase in newly bred T. spelta varieties. They are unlikely to attract the interest of organic farmers who have a preference for “true spelt”, but the nutritional value of grain of modern spelt cultivars will surpass that of bread wheat grain.

The present study was undertaken to expand the existing knowledge about hybrids between bread wheat and spelt and to generate useful information for breeding purposes. In the studied hybrids, 50% of the genes were derived from each parent (T. spelta and T. aestivum), unlike in modern spelt cultivars intended for intensive farming, which harbor only a small proportion of bread wheat genes. The results clearly indicate that bread made from the flour of T. spelta × T. aestivum hybrids is characterized by superior attributes, compared with bread made from spelt flour. These hybrids represent a new category of crops with novel characteristics, in particular traits that are desirable from the agricultural point of view. The results of this study provide valuable inputs for expanding the biodiversity of agricultural phytocenoses, reducing pressure from pests and pathogens, and promoting sustainable cereal production.

CONCLUSIONS

The examination of 36 lines derived from single crosses between bread wheat and spelt indicates that gluten content was significantly higher in the grain of hybrid lines than in bread wheat, and it did not differ significantly from that noted in spelt grain. The gluten index did not differ significantly between hybrid lines and bread wheat. Protein content was significantly higher in the flour obtained from hybrid lines than from bread wheat. Breads made from the grain of hybrids were characterized by high quality and superior attributes relative to breads made from spelt flour. The study demonstrated that hybrids between T. spelta and T. aestivum can become a new, valuable source of grain for bread production.