INTRODUCTION

It is estimated that the world population will reach almost 10 billion by 2050, which causes a sharp increase in the demand for food, especially for proteins of animal origin, accounting for about 40% of the global demand. Production of animal protein is incredibly expensive and energy consuming. The Food and Agriculture Organization of the United Nations (FAO) estimates that it will only be possible to feed more than 9 billion people, the projected world population in 2050, if food production is increased by 70%. Almost 80% of the world’s arable land is already used for livestock farming, and global meat consumption is projected to increase by 26% by the year 2050. World fish production would need to increase by 50% from 2006 levels to meet the demand identified for 2050 [FAO, 2009; Gladek et al., 2017; van Huis et al., 2013]. On the other hand, climate change and food waste are other factors contributing to food decline worldwide [Tomaszewska et al., 2022]. In this context, insects can be seen as an alternative to existing food products [Skotnicka et al., 2021]. They have a high feed conversion ratio: an average of 2 kg of feed per 1 kg of insect weight gain, while cattle production requires 8 kg of feed per 1 kg of weight gain [FAO, 2021; Oonincx & de Boer, 2012]. Their 1,900 species are now used as food [van Huis et al., 2013] in many parts of the world, mainly in Asia, Africa, and Latin America, by an estimated population of at least 2 billion people [FAO, 2021].

Entomophagy may be the answer to one of the greatest challenges posed today, which is ensuring food security. The FAO calls for increased efforts to improve the acceptance and use of insects in food production, which is an element of sustainable development [van Huis et al., 2013]. It should be underlined that consumption of 100 g of caterpillars covers about 70% of the daily protein demand and 100% of the vitamin demand [Rumpold & Schlüter, 2013]. One of the many insects considered to be edible is the mealworm (Tenebrio molitor), which is used in the larval stage for food or feed purposes. These larvae are also used to obtain protein preparations, the fat fraction as well as the so-called insect meal or insect flour which is obtained by grinding freeze-dried or conventionally dried larvae [Bußler et al., 2016]. The mealworm larvae are rich in such nutrients as proteins (about 65 g/100 g), lipids (about 28 g/100 g), phosphorus and potassium (about 697 and 761 mg/100 g, respectively), and vitamin C (about 36 mg/100 g) [Jantzen da Silva Lucas et al., 2020]. Considering the amino acid profile of the mealworm protein, it is worth noting that it contains more isoleucine, leucine, valine as well as phenylalanine and tyrosine than beef protein [Rumpold & Schlüter, 2013].

Therefore, edible insects may not only diversify the daily diet, contribute to food and nutritional security, but also have an impact on the reduction of the carbon footprint compared to the production of protein from farm animals [Vauterin et al., 2021]. Edible insects are known to be of use in variety of food products, including cricket powder for the production of muffin [Pauter et al., 2018]; Hermetia illucens, Acheta domesticus, Alphitobius diaperinus and Tenebrio molitor flours for bakery products [González et al., 2019; Kowalski at al., 2022; Wu et al., 2020], A. diaperinus and A. domesticus for pancakes [Skotnicka et al., 2022] as well as mealworm larvae as a meat substitute in the production of hamburgers [Megido et al., 2016].

One of the key parameters of a food is its texture, which, in addition to technology, is influenced by the chemical composition of raw materials used in the production process. Kowalski et al. [2022] and Roncolini et al. [2019] reported a decrease in the hardness of bread baked with mealworm flour addition in comparison to bread with wheat flour. Whereas Pauter et al. [2018] observed an influence of cricket powder on a decrease in the hardness, springiness, chewiness, and resilience of muffins. Xie et al. [2022] also determined the influence of mealworm flour on a decrease in the hardness of sponge cakes and an increase in cohesiveness, chewiness, and resilience with an increase in the share of this flour from 5 to 15% in sponge cake formula. Reducing the hardness of products with insect flours may result from the weakening of the gluten structure as a result of the addition of a glutenfree ingredient. On the other hand, the increase in the value of other texture parameters may be due to the higher protein content, which may contribute to the strong binding of protein and starch by hydrogen bonds, which were formed during dough development and baking [Sriprablom et al., 2022; Xie et al., 2022].

The aim of our research was to evaluate impact of ground mealworm larvae on the sensory acceptance, and the physicochemical and textural properties of confectionary products, using sponge cake as a model. To eliminate the influence of the dough matrix, chicken eggs were replaced in formulations with a low-protein egg replacer, which made the analysis of amino acids and fatty acids more reliable.

MATERIAL AND METHODS

Materials used to sample preparation

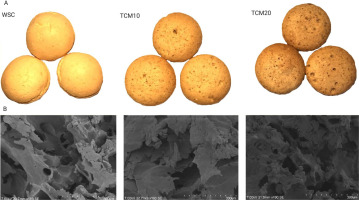

The study samples were wheat sponge cake (WSC) and sponge cake in which part of the wheat flour type 450 (GoodMills Polska Sp. z o.o., Stradunia, Poland) was replaced by flour from ground mealworm (ZIRP Insects, Wien, Austria) in quantities of 10% (TMC10) and 20% (TMC20), on the initial wheat flour weight basis. The sponge cakes were prepared from a low-protein egg replacer (ER) (Natura-Werk Gebr. Hiller GmbH & Co.KG, Hannover, Germany) and sugar powder (Pfeifer & Langen Marketing Sp. z o.o., Poznan, Poland).

Sponge cake preparation

The sponge cakes were made using the cold method with the eggs:sugar:flour ratio of 2:1:1 (w/w/w) (Table 1). The dough was prepared using an Aristan 7 mixer (KitchenAid, Benton Harbor, Berrien, MI, USA). The low-protein egg replacer and water were mixed in the mixing bowl for 1 min at speed 2, then beaten for 5 min at speed 10. Sugar powder was added and the dough was again beaten for 3 min at speed 8, then sieved flour was added and the dough was mixed for 1 min at speed 2. The dough was allowed to stand for 10 min and then poured into silicone moulds (dimensions 30 mm) using a confectionery sleeve. The cakes were baked in a Miwe roll-in oven (Arnstein, Germany), at 200°C, for 12 min. When cooked, they were cooled down for half an hour at 19°C and used for further analyses.

Consumer acceptance analysis

Fifty participants aged 19 to 51 took part in the study. They were qualified from a randomly selected sample. Each participant assessed all cake variants proposed in the study. The study participants were healthy and did not take any food or medications that might affect their sensory evaluation. They took part in the research on a voluntary basis and the formal side of the research was approved by the Independent Bioethical Research Committee of the Medical University of Gdańsk (NKBBN/346/2021). Before the study, all of them completed the food neophobia test (FNS), which was a condition for proceeding to the next stage of the study. They evaluated the appearance, aroma, taste, structure, and overall acceptance of the sponge cakes in a double-blind test, using a 5-point Likert scale (with 5 meaning excellent and 1 meaning extremely unsatisfactory).

Analysis of nutrient composition

The following parameters of wheat and mealworm flour, low-protein egg replacer and sponge cake were analyzed using AOAC International methods: ash content (AOAC 923.03); protein content (AOAC 950.36); crude lipid content (AOAC 935.38); water content (AOAC 925.10); total, soluble, and insoluble dietary fiber content (AOAC 991.43) [AOAC, 2006]. Analyses was performed in duplicate. Results were expressed as g/100 g dry matter (d.m.) ± standard deviation (SD).

Color analysis

The color of sponge cakes was analyzed using a Konica Minolta CM-5 spectrophotometer (Konica Minolta Sensing, Osaka, Japan) in the CIElab (L*, a*, b*) system with 8 mm shutter, D65 illuminant, and 10° angle of measurement. The test temperature was 21°C. Measurements were done at ten different places on the surface of each sponge cake. The average color parameters from the measurements (were L* value indicates lightness; the a* value indicates red-green component (redness), and the b* value yellow and blue components (yellowness) of a color) were determined, which were used to calculate the total color difference (ΔE) using the formula (1) [Fernández-Artigas et al., 1999]:

where: ΔL* – lightness difference, Δa* – redness difference, Δb* – yellowness difference.Based on the values of L*, a* and b* parameters, the browning index (BI) was estimated [Buera et al., 1985] as follows (2):

where:Texture analysis

For the examination of the textural changes during storage, the sponge cakes were packed in polyethylene film pouches (HDPE) and stored for 30 days at ambient temperature (20±1°C, 65% relative humidity (RH). Measurements of the snapping force and deflection of sponge cakes, such as hardness (peak force) and fracturability (the first significant break), were performed using a single-arm TA.XT2.Plus texture analyzer (stable Micro System Ltd, Godalming, Surrey, United Kingdom). A three-point bend rig (HDP/3PB) with the base’s adjustable gap set at 20 mm using 5-kg load was used, with the trigger force 0.196 N, distance 5 mm. The texture parameter examination of the sponge cake was done after 1, 7, 14, 21, and 30 days of storage. Measurements were done in ten repetitions.

Scanning Electron Microscopy (SEM)

The structure of sponge cakes was observed using the HITACHI S-3400 N scanning electron microscope (Santa Clara, California, USA) Working parameters were as follows: Accelerating voltage 7.00 kV, emission current 60.0 μA, working distance 30.7 mm.

Determination of fatty acid profile

The derivatization and determination of fatty acid composition were performed according to the AOAC International approved method 991.39 [AOAC, 2006]. The analysis was performed as described by Kowalski et al. [2020] using a Shimadzu GC2010Plus chromatograph (Shimadzu corp., Kyoto, Japan) with a flame ionization detector (FID). Analyses was performed in duplicate, and results were expressed as g/100 g total fatty acids.

Nutritional quality indexes of lipids

The nutritional quality of sponge cake lipids was evaluated using five indexes: the ratio of hypocholesterolemic to hypercholesterolemic fatty acids (HH) (4), the atherogenic index (AI) (5), and thrombogenicity index (TI) (6), the ratio of polyunsaturated fatty acids to saturated fatty acids (PUFA/ SFA), and the ratio of n–6 fatty acids to n–3 fatty acids (n6/n3) [Ulbricht & Southgate, 1991].

where: MUFA – monounsaturated fatty acids,Amino acid analysis

Amino acid analysis was performed according to the method of Moore & Stein [1951]. Lyophilized samples were hydrolyzed in liquid 6 M HCl with 0.5% (w/v) phenol at 110°C for 24 h under an argon atmosphere. The hydrolysates were lyophilized, dissolved in buffer (0.2 M sodium citrate buffer, pH 2.2), filtered through a 0.45 μm syringe filter, and analyzed using the chromatographic amino acid analyzer (AAA400, Ingos, Prague, Czech Republic). Amino acids were analyzed by ion-exchange chromatography, with a cation exchanger and a sodium-citrate elution buffer system followed by post-column derivatization with ninhydrin and spectrophotometric detection at 570 and 440 nm, according to the standard protocol of the manufacturer. Sulphur-containing amino acids were analyzed as oxidation products obtained by performic acid oxidation followed by the standard hydrolysis procedure with HCl. For calibration of the amino acid analyzer, the amino acid analytical standard (mixture of amino acids, Sigma-Aldrich, Saint Louis, Missouri, USA) was used in the concentration of 2.5 mM in 0.1 N HCl. Evaluation of the acquired data was performed using the software of the chromatographic device (Chromulan, Pikron, Prague, Czech Republic). Tryptophan was not determined as it is destroyed during acid hydrolysis, and asparagine and glutamine turn to aspartic acid and glutamic acid and in these forms are determined. Results were expressed as mg/g protein.

Nutritional quality of protein

Based on the amount and type of amino acids, the nutritional value of protein, expressed as the amino acid score (AAS), was calculated according to FAO/WHO [1991] (7):

*recommended amino acids scoring patterns for adolescents and adults, according to FAO [2013].Microbiological analysis

For the examination of the microbiological changes during storage, the sponge cakes were packed in polyethylene film pouches (HDPE) and stored at ambient temperature (20±1°C, 65% RH). Their microbiological analyses were performed at the 1st and the 30th day of storage [Mikulec et al., 2020]. Samples were prepared according to International Organization for Standardization (ISO) 6887-1:2017 method [ISO, 2017]. In brief, 10 g of chipped sponge cakes were weighed and 90 mL of sterile saline were placed in a homogenizer bag, and homogenized in a BagMixer 400 W lab blender (Interscience, Saint Nom la Bretêche, France) for 3 min, speed 8 beats/s. The total number of aerobic amylolytic bacteria was determined by pouring 1 mL of each decimal dilution with Waksman medium (Biocorp Polska Sp. z o.o., Warsaw, Poland). After the incubation period (48 h, 37°C), the ability of the bacteria to produce amylase was observed by the appearance of a clear yellow zone around the colony by flooding it with Lugol’s iodine solution according to PN-A-74134-4:1998 method [Polish Committee for Standardization, 1998]. To determine the total number of yeast and mold, 1 mL of appropriate decimal dilution was transferred into Sabouraud agar with chloramphenicol (Biocorp). The plates were incubated at 25°C for 3 to 5 days in line with ISO 21527-2:2008 method [ISO, 2008]. The number of β-glucuronidasepositive Escherichia coli was determined according to ISO 16649-2:2001 method [ISO, 2001]. The number of coagulase-positive staphylococci (Staphylococcus aureus and other staphylococci) was determined ISO 6888-1:2021 method with Baird-Parker agar medium [ISO, 2021], and the number of Bacillus cereus bacteria was determined according to ISO 7932:2004 procedure [ISO, 2004]. The results were expressed as cfu/g sponge cake. Measurements were done in two replicates.

Statistical analysis

Statistical analysis was carried out using Statistica 13.0 (StatSoft, Krakow, Poland). A one-way ANOVA was used to test sponge cake features at p<0.05. When ANOVA indicated significant differences, a post-hoc least significant difference (LSD) Fisher’s test was performed. The results were presented as means ± SD.

In the consumer assessment, assuming that the simultaneous use of many explanatory variables will serve to increase the accuracy of prediction, the parameters of the equation describing the influence of sensory factors in the tested samples on the level of perceived acceptance after their consumption were estimated. For this purpose, the parameters of multiple regression were estimated, taking into account the concept of shared variability in the Excel 2010 PL (Microsoft Sp. z o.o., Warsaw, Poland) spreadsheet. At the stage of planning the experiment, the selection of the sample size at a level that would produce statistical conclusions, the appropriate accuracy and certainty as well as the probability of the test to detect the effects of the given size was examined on the basis of the test power analysis and the interval estimation of the sample size. Quantitative variables were characterized using the arithmetic mean and SD.

RESULTS AND DISCUSSION

Consumer acceptance

Consumer acceptance is undoubtedly a key parameter that determines the possibility of introducing a new product to the market. A high nutritional value must be accompanied by sensory attractiveness [Sun-Waterhouse & Wadhwa, 2013]. Taste, aroma, and appearance are some of the most important factors that influence the consumer’s purchasing decision. Consumption of edible insects or products with their participation may be associated with nutritional neophobia and cultural prejudices. As already mentioned above, the consumer acceptance may be influenced by the texture and its relation to the taste sensations. As part of the undertaken research, the organoleptic acceptance of sponge cakes with mealworm flour was assessed. All of the considered descriptors (appearance, aroma, taste, and texture) were related to the acceptance level of the analyzed samples. Therefore, a hypothesis was formulated assuming that the acceptance of sponge cakes with the addition of mealworm flour is the resultant of the appearance, taste, aroma, and texture. The analysis of the values of the general quality ratings of the tested samples showed that traditional sponge cakes without the addition of insect flour received the highest level of acceptance (Table 2). The control sample containing no insects turned out to be the highest rated in terms of all traits. The results show that the addition of insect flour significantly deteriorated the acceptance of sponge cakes, both in the case of 10% of the addition and its double. This indicates that the amount of the additive was not the main determinant but the additive itself, which affected the appearance, aroma, taste, and texture of the products. However, the overall acceptance evaluation of the samples with the addition of mealworm flour was assessed at 3.82 and 3.80 for TMC10 and TMC20, respectively, which indicates some acceptability and gives information that the use of insect flour in human nutrition could be accepted and implemented in industrial production (Table 2).

Table 2

Acceptance values for the characteristics of the organoleptic quality of sponge cakes.

[i] A 5-point Likert scale was used for the evaluation of sponge cakes. The results are presented as mean and standard deviation (n=50). Values in the same column marked with different letters are statistically significantly different at p<0.05. WSC – wheat sponge cake; TMC10 – sponge cake with 10% addition of mealworm flour; TMC20 – sponge cake with 20% addition of mealworm flour.

The results of the organoleptic analysis became the basis for estimating the relationship between the acceptance of selected characteristics of the organoleptic quality of sponge cakes with the addition of insect flour and the general acceptance of sponge cakes. For this purpose, multiple regression analysis was used, which allowed for the development of acceptance models for the tested samples. The dependent variable was the sponge cake acceptance level, while the input independent variables were the acceptance ratings of individual organoleptic quality characteristics, such as taste, aroma, appearance, and texture. Independent variables were reduced to critical parameters. The significance of the generated acceptance models was assessed at the significance level of p<0.05. The model used to estimate the influence of particular variables on the assessment of the acceptance of sponge cake with the addition of 10% of insect flour turned out to be statistically significant, and all predictors explained 97% of the variability of the dependent variable (R2=0.97). All the included predictors had a significant impact on the assessment of the acceptance of insect flour sponge cakes: acceptance of appearance (p=0.014), taste (p=0.000), aroma (p=0.002), and texture (p=0.004).

Taking the above descriptors into account, the regression equation took the following form (8):

In the case of the evaluation of the acceptance of sponge cakes with the addition of 20% insect flour, the coefficient of determination assumed the value of R2=0.97, which indicates that the generated model explained 97% of the variability of the dependent variable, i.e., the acceptance of TMC20 sponge cakes, and 3% of the variability remained in the residual variable. As in the case of the smaller amount of mealworm flour addition, all the included predictors also had a significant impact on the sponge cake acceptance assessment: acceptance of appearance (p=0.008), taste (p=0.002), aroma (p=0.012), and texture (p=0.000).

Based on the large-scale regression analysis, an acceptance model for sponge cakes with 20% insect flour was generated. Taking the above descriptors into account, the regression equation took the following form (9):

The obtained results indicate that the level of acceptance was the result of the predictors included in the regression equation. The taste and texture of both the TMC10 and TMC20 variants were of greatest importance for the overall acceptance of the sponge cakes with the addition of insect flour.

The present study results corroborate literature data. For example, Roncolini et al. [2019] reported a decrease in consumer acceptability of bread enriched with T. molitor flour; however, they found no effect of the additive level (5 and 10%) on the overall product acceptability. García-Segovia et al. [2020] analyzed breads with T. molitor and A. diaperinus at the same percentage of enrichment as in the previous work. However, they concluded that the decrease in consumer acceptability was directly proportionally correlated with the amount of insect flour added. Furthermore, breads with mealworm were rated higher than those with A. diaperinus flour. On the other hand, in our previous research on breads with cricket, buffalo worm and mealworm powder (from 10 to 30%), we found that the 10% share of these flours in breads did not lower consumer acceptance [Kowalski et al., 2022]. In the study by Pauter et al. [2018], consumers perceived the appearance and color of a muffin with 2, 5, and 10% cricket powder as unattractive. On the other hand, an increase in acceptance in the assessment of taste and texture was observed, compared to the control, even though some consumers indicated a noticeable “unpleasant” taste. The authors suggest that a 2% share would be acceptable to consumers [Pauter et al., 2018].

Nutrient composition

Food is a combination of various components that provides the necessary nutrients for cell growth and proliferation. They also fuel cellular metabolism. However, in addition to these roles, it is clear that nutrients and their metabolites are also active in facilitating, regulating, and coordinating the vast number of cellular processes that aim to maintain cellular homeostasis [Chen et al., 2018]. Therefore, the chemical composition of food determines its nutritional value and suitability for human nutrition. Based on the LSD Fisher’s test, all analyzed samples differed significantly (p<0.05) in terms of nutritional value (Table 3). Mealworm flour had a significantly (p<0.05) higher ash, protein, and lipid content compared to wheat flour, which translated into a higher content of these ingredients in sponge cakes compared to the control. It should be emphasized that sponge cake with mealworm flour was also characterized by a significantly higher content of insoluble dietary fiber fraction. The results of the chemical composition of mealworm flour (Table 3) are consistent with those obtained by other authors, who determined a similar content of nutrients and especially protein, lipid, and ash (41.22 to 52.23%; 29.42 to 32.76 % and 3.57 to 4.30% respectively) [González et al., 2019; Khuenpet et al., 2020; Wu et al., 2020]. Other authors also observed an increase in the content of nutrients as a result of supplementing the products, like bread or muffins with an edible insects flour richer in individual nutrients [González et al., 2019; Khuenpet et al., 2020; Kowalski et al., 2020; Pauter et al., 2018].

Table 3

Nutritional value of raw materials and sponge cakes (g/100 g).

[i] The results are presented as mean and standard deviation (n=2). Values in the same column marked with different letters are statistically significantly different at p<0.05. WF – wheat flour; TM – mealworm flour; ER – low-protein egg replacer; WSC – wheat sponge cake; TMC10 – sponge cake with 10% addition of mealworm flour; TMC20 – sponge cake with 20% addition of mealworm flour.

Color parameters

Color is one of the key features of bakery products and, in addition to textural features, can affect consumer acceptance. In the one-way ANOVA, the LSD Fisher’s test showed a significant (p<0.05) effect of edible insects flour on the CIELab parameters as well as on both total color difference and browning index (Table 4). With mealworm flour addition to cake formulation, a decrease in lightness (L*), an increase in the content of redness (a*) and yellowness (b*) color components, an increase in the total color difference, and an increase in the BI value were observed. A similar effect in changing the values of color parameters (Table 4) was observed by Pauter et al. [2018], who used cricket flour to make muffins. They found a significant decrease in L* and ΔE with an increase in the proportion of insect flour, while observed a significant decrease in the values of a* and b* parameters, in contrast to our study.

Table 4

Color parameters of sponge cakes.

| Sponge cake | L* | a* | b* | ΔE | BI |

|---|---|---|---|---|---|

| WSC | 78.29±0.17a | 5.05±0.15c | 23.22±0.59b | – | 38.81±1.28c |

| TMC10 | 71.93±0.63b | 6.33±0.17b | 25.18±0.57a | 6.79±0.79b | 48.19±1.86b |

| TMC20 | 67.11±0.13c | 7.56±0.03a | 25.17±0.25a | 11.63±0.14a | 53.78±0.61a |

[i] The results are presented as mean and standard deviation (n=12). Values in the same column marked with different letters are statistically significantly different at p<0.05. WSC – wheat sponge cake; TMC10 – sponge cake with 10% addition of mealworm flour; TMC20 – sponge cake with 20% addition of mealworm flour; L* – lightness; a* – redness; b* – yellowness; ∆E – total color difference, BI – browning index.

Texture parameters

All the mealworm flour sponge cakes were characterized by significantly (p<0.05) lower hardness compared to the control cake (WSC) (Table 5). The hardness of the control sponge cakes was at a similar level over the entire storage period. The lowest hardness was determined for the sponge cakes with 20% mealworm flour addition on the baking day and after 7 days of storage, and in the sponge cakes with 10% mealworm flour addition after 7 days of storage. Wheat sponge cake, on the baking day, showed significantly greater fracturability (75.43 N), compared to the other cakes, both on the baking day and during storage, which ranged from 27.70 N (TMC10 baking day) to 68.09 N (WSC after 30 days). Both the hardness and fracturability of the sponge cakes with insect flour increased from the 14th day of storage. Mealworm flour contributed to a significant reduction in their fracturability compared to WSC. Our results are in line with the literature data. Pauter et al. [2018] found lower hardness of muffins with cricket flour compared to muffins without additives. A significant effect on the reduction of hardness of breads with mealworm, regardless of the amount of the additive, was also observed in our previous work [Kowalski et al., 2022]. In turn, Feili et al. 2013] claimed that the hardness of bakery products depended mainly on their amylopectin and amylose contents. The protein content increase and the starch content decrease were reported by produce a significant decrease in hardness [Gómez et al., 2003; Martínez-Cervera et al., 2011]. Rodríguez-García et al. [2014] also concluded that hardness was related to the total air cell volume and crumb volume, and as the gas cell size increased, the crumb structure of the product became softer and more delicate. The observed changes may stem from gluten dilution due to the substitution of a part of wheat flour with a gluten-free additive, which is mealworm flour. In addition to the gluten dilution effect, Xie et al. [2022] explained the reduction in hardness of cookies with the addition of mealworm by competition for water particles. The above-mentioned effects affected the structure of the sponge cakes, which seems to be confirmed by the SEM images (Figure 1), which clearly show that the structure of WSC was more porous and its pore walls were thinner compared to the structure of TM10 and TM20.

Table 5

Texture parameters of sponge cake stored for 30 days.

[i] The results are presented as mean and standard deviation (n=10). Values in the same column marked with different letters are statistically significantly different at p<0.05. WSC – wheat sponge cake; TMC10 – sponge cake with 10% addition of mealworm flour; TMC20 – sponge cake with 20% addition of mealworm flour.

Fatty acid profile

Significant differences were observed in the content and profile of fatty acids both in the raw materials used to produce sponge cakes and in the finished products (Table 6). The fatty acid profile of mealworm flour and sponge cakes with its addition was dominated by monounsaturated fatty acids with the highest content of oleic and linoleic fatty acids. The nutritional value of flours and sponge cakes was evaluated by nutritional quality indexes of lipids such as AI, HH, TI, PUFA/SFA, and the n6/n3 ratio. AI and TI ranged from 0.24 and 0.38 for WSC respectively, to 0.56 and 0.78 for TMC20, respectively. HH of sponges cake lipids ranged from 2.56 for TMC20 to 4.25 for WSC. The PUFA/SFA ratio of the sponge cake with mealworm flour was lower compared to that of WSC, i.e., 0.95 (TMC20) vs. 3.57 (WSC). In turn, the n6/n3 ratio increased from 15.85 for WSC to 27.10 for TMC20. Similar results of the fatty acid profile of the mealworm oil fraction were obtained by Wu et al. [2020]. AI and TI can be used as predictors or risk factors for cardiovascular diseases and should be kept at low levels in a healthy everyday diet [Ulbricht & Southgate, 1991]. The HH index is an indicator of the effect of fatty acids on cholesterol metabolism and its high value is important from a nutritional point of view. According to nutritionists [Simopoulos, 2008], the n6/n3 ratio should range from 1:1 to 5:1, while the ratio of 10:1 has adverse health consequences. A low level of PUFA/SFA ratio in diets is deemed to be a risk factor for increased blood cholesterol levels [Pacetti et al., 2013]. Thus, the lipid fractions of raw materials and sponge cakes were characterized by too high values of the n6/n3 ratio (Table 6). Taking into account lipid indexes, the addition of mealworm flour to the formulations of studied sponge cakes diminished their nutritional quality. However, it is difficult to unequivocally assess the nutritional value of insect lipids only on the basis of lipid indexes and the ratio of its individual fractions, because, for example, oleic acid, the content of which in the lipid profile of sponge cakes with mealworm was over 4 times higher than in the control cake, has a beneficial effect on insulin sensitivity [Palomer et al., 2018]. This acid not only prevents insulin resistance but also inhibits endoplasmic reticulum stress and anti-inflammatory effects, as well as prevents attenuation of the insulin signaling pathway, and improves β-cell survival [Palomer et al., 2018]. Research by Perona et al. [2004] demonstrated the effectiveness of oils rich in oleic acid in lowering blood pressure and low-density lipoprotein (LDL) cholesterol level [Perona et al., 2004]. Additionally, in the diet, a low ratio of palmitic to oleic acids also contributes to a reduced risk of diabetes development [Palomer et al., 2018]. The palmitic acid content of the sponge cakes, compared to oleic acid, was 0.50 (TMC10) and 0.57 (for TMC20), compared to 2.07 determined for WSC (Table 6), suggesting some potential for reducing the risk of diabetes development.

Table 6

Raw material and sponge cake fatty acid profiles (g/100 g total fatty acids) and nutritional quality indexes of lipids.

[i] The results are presented as mean and standard deviation (n=2). Values in the same row marked with different letters are statistically significantly different at p<0.05. WF – wheat flour; TM – mealworm flour; ER – low-protein egg replacer; WSC – wheat sponge cake; TMC10 – sponge cake with 10% addition of mealworm flour; TMC20 – sponge cake with 20% addition of mealworm flour; SFA – saturated fatty acids; MUFA – monounsaturated fatty acids; PUFA – polyunsaturated fatty acids; AI – atherogenic index; HH – ratio of hypocholesterolemic to hypercholesterolemic fatty acids, TI – thrombogenicity index

Amino acid profile

The quality of a protein depends on its amino acid profile and digestibility [van Huis et al., 2013]. Mealworm flour and sponge cakes with its addition were characterized by a significantly higher content of essential amino acids (Table 7) and the sum of aromatic amino acids (phenylalanine and tyrosine) which ranged from 345.43 to 304.14 and 118.36 to 93.23 mg/g protein, respectively (Table 7). Among the essential amino acids, the major ones were leucine, valine, lysine, and phenylalanine. The amino acid score was calculated by comparing the content of essential amino acids to the FAO standard [FAO, 2013]. The addition of mealworm flour did not change the limiting amino acid of the control sponge cakes, i.e. lysine, but the amino acid score was twice as high and amounted 63.04–63.10% for the mealworm sponge cakes compared to wheat sponge cake (30.38%) (Table 7). It should be emphasized that the addition of insect flour contributed to the improvement of the composition of most essential amino acids (except lysine) of sponge cake proteins to the values in line with the FAO recommendations [2013] (Table 7). The obtained results are consistent with those reported by other authors who also determined the amino acid profile in the mealworm flour [Jantzen da Silva Lucas et al., 2020; Wu et al., 2020].

Table 7

Amino acid profiles and amino acid scores of raw materials and sponge cakes.

[i] The results are presented as mean and standard deviation (n=2). Values in the same row marked with different letters are statistically significantly different at p<0.05. WF – wheat flour; TM – mealworm flour; ER – low-protein egg replacer; WSC – wheat sponge cake; TMC10 – sponge cake with 10% addition of mealworm flour; TMC20 – sponge cake with 20% addition of mealworm flour; EEA – essential amino acids; SAA – sulphur-containing amino acids; AAA – aromatic amino acids.

Microbiological quality and stability

The microbiological assessment of food is essential to verify its suitability for safe human consumption. In 2015, the European Food Safety Authority (EFSA) issued a scientific opinion on the risk profile of the production and consumption of insects as food and feed [EFSA Scientific Committee, 2015]. Therefore, pursuant to the Regulation (EU) 2015/2283 of the European Parliament and of the Council on novel foods and the commercialization of food containing insects and their parts, it must be authorized by the European Commission (EC) after EFSA has carried out a safety risk assessment. Edible insects and their products contain complex communities of microbes that originate from their digestive tract or from their breeding and processing environment. They are likely to contain saprophytic, spoilage or potentially pathogenic microorganisms [Osimani et al., 2018a, b, c]. In our study, microbiological analysis did not reveal the presence of pathogens in the raw materials and in the finished products. After baking, the sponge cakes were microbiologically clean, and after 30 days of storage, a slight increase was observed in the counts of fungi and bacteria (Table 8). The obtained results are similar to those reported by other authors who analyzed the microbiological quality of bread with mealworm [Roncolini et al., 2019] and cricket powder [Osmiani et al., 2018b]. Roncolini et al. [2019] found insignificant amounts of aerobic bacterial spores in bread crumb, which could be due to their temperature resistance, which when baked in the thermal center of the loaves was below 100°C. On the other hand, Osimani et al. 2018b] detected spore-forming bacteria in bread loaves with cricket powder, which may indicate a potential food safety problem. Small counts of bacteria and fungi were observed in the sponge cakes only after 30 days of storage. It is worth emphasizing, however, that these microorganisms were found in much higher numbers in the control sponge cakes. Thus, the low moisture content (from 6.16 for WSC to 7.85% for TMC10) (Table 3) and high temperature of baking probably protected the finished products from the development of pathogenic food microflora.

Table 8

Microbiological characteristic of raw materials and sponge cakes (cfu/g).

[i] The results are presented as mean and standard deviation (n=2). Values in the same column (separately for raw material, sponge cake baking day and sponge cake 30 day storage) marked with different letters are statistically significantly different at p<0.05. WF – wheat flour; TM – mealworm flour; WSC – wheat sponge cake; TMC10 – sponge cake with 10% addition of mealworm flour; TMC20 – sponge cake with 20% addition of mealworm flour; TNB – total number of bacteria; TNF – total number of fungi; NAB – the number of amylolytic bacteria; Pathogens – Escherichia coli, Bacillus cereus, Staphylococcus Aureus; Nd – not detected.

CONCLUSIONS

Replacing 10–20% of wheat flour with mealworm flour reduced the organoleptic properties of the sponge cakes. The level of acceptance was mainly affected by changes in the taste and texture of supplemented products. However, it should be emphasized that the acceptance of sponge cakes with mealworm flour was not much lower than that of the control wheat sponge cakes. The addition of mealworm flour contributed to the increase in the nutritional value of the final products. Sponge cakes prepared from flour with insect powder were characterized by lower hardness and fracturability both on the baking day and throughout the 30-day storage. Except for lysine, which was the limiting amino acid in all sponge cakes, the mealworm flour cakes were characterized by a higher content of all amino acids compared to the FAO recommended standard. The addition of mealworm flour did not diminish the microbiological quality of the sponge cakes, and after a 30-day storage period, TMC10 and TMC20 showed lower numbers of amylolytic bacteria and total bacteria compared to the control cakes.