INTRODUCTION

Dietary fiber is generally known as edible parts of plants, including polysaccharides and lignin, that are resistant to enzymatic digestion in the human intestine [Prosky, 2000]. Its frequent intake exerts various positive effects on reducing cholesterol levels, blood pressure, incidence of cardiovascular diseases and some types of intestinal problems. Additionally, food antioxidants play an essential role in promoting human immune system and preventing free radical-related diseases [Brambilla et al., 2008]. Dietary fiber and antioxidants from a variety of plant sources have been added to various food products such as bakery [Salehi & Aghajanzadeh, 2020] and pasta products [Bianchi et al., 2021; Nguyen et al., 2023; Ta et al., 2023] to enhance their health-promoting properties.

Crackers are a common type of bakery products around the world due to low price, ease of consumption, and long shelf-life [Tiwari et al., 2023]. Wheat crackers are rich in starch but poor in dietary fiber and antioxidants; as a result, their nutritional composition is not well balanced [Ujong et al., 2023]. Recently, crackers have been supplemented with dietary fiber and antioxidants from by-product flours of the agri-food industry to improve their health effects [Chatziharalambous et al., 2023].

Asparagus (Asparagus officinalis L.) is a widely known vegetable which contains flavonoids and other phenolic compounds with strong antioxidant activity [Nindo et al., 2003]. In agricultural production, the harvested asparagus spear accounts for about 20-25% of the total weight of the trees, while the by-products including hard-stem leftovers and roots account for 70-75% [Chitrakar et al., 2019]. High levels of dietary fibers and phenolics are reported in asparagus hard-stem [Nielsen, 2010], but the use of this by-product for food formulation has not been considered.

In the present study, various ratios of asparagus hard-stem powder (AHP) were added to the cracker recipe to improve dietary fiber content and antioxidant capacity of the fortified crackers. The aim of the research was to clarify the impacts of AHP addition on the nutritional composition, antioxidant capacities, physical attributes and sensory acceptability of crackers. The effects of water amounts used in the recipe of high-fiber crackers on their textural and sensory quality were examined as well.

MATERIALS AND METHODS

Materials and chemicals

Asparagus hard-stems were collected from an asparagus (Asparagus officinalis L.) field in Cu Chi district, Ho Chi Minh City. The collected asparagus hard-stems were washed with municipal water, sliced to 5-mm thick pieces, and dried at 50oC for 2–2.5 h to reach the moisture content of 10–12 g/100 g. The dried hard- -stems were then ground and sieved through a 70-mesh screen (0.210 mm) to obtain AHP which was preserved in plastic bags at 4oC for further experimentation.

Ingredients for cracker making including wheat flour, cooking oil, refined saccharose, baking powder, sodium chloride, calcium dihydrogen phosphate, and lecithin were bought in a local supermarket.

All chemicals of analytical grade were from Sigma-Aldrich Inc. (Saint Louis, MO, USA); commercial enzymes, including Dextrozyme® GA, Termamyl® S, and Alcalase® 2.5 L, used for fiber determination were from Novozymes A/S (Bagsværd, Denmark).

Experimentation

The flour blend included wheat flour and AHP. In the making of dietary fiber-enriched crackers, the weight ratio of AHP to total flour blend (200 g) was 0% (control sample), 5%, 10%, 15%, and 20%. Other ingredients included: 28 g cooking oil, 10 g refined saccharose, 0.52 g lecithin, 0.58 g calcium dihydrogen phosphate, 4.08 g baking powder, 1.46 g salt, and 90 g water.

The cracker making process began with mixing the cooking oil, sugar, and lecithin within a mixer (5KSM7590, KitchenAid, Benton Harbor, MI, USA) at a speed of 200 rpm for 1 min. Calcium dihydrogen phosphate was dissolved in a required volume of water and then added to the mixture, which was mixed at 300 rpm for another 1 min. A mixture of wheat flour, AHP, baking powder, and sodium chloride was finally added and kneaded at 100 rpm for 11 min. The obtained dough was then incubated for 12 min in a convectional incubator (V222, Incucell, Munich, Germany) and flattened to 2 mm thickness by a rolling pin. The rolled dough was shaped using molds with a diameter of 42 mm and pricked with a fork. The crackers were baked at 230oC for 10 mins in an oven (VH-309N2D, Sanaky, Ho Chi Minh city, Vietnam), and the moisture of all cracker samples was less than 5 g/100 g. After baking, the crackers were naturally cooled down to 25oC and preserved in zip-lock bags for 1 day before analysis.

In order to enhance quality of the AHP-fortified crackers, the water amount used in the kneading of 20% AHP added sample was 90, 100, 110, 120 g/200 g flour blend. Other ingredients and the procedure of cracker making were fixed as mentioned above.

Analytical methods

Determination of chemical composition

Wheat flour, AHP, and crackers were analyzed to determine their chemical composition according to the methods of the Association of Official Analytical Chemists [AOAC International, 2023]. Moisture content was determined by AOAC 925.10 method. Protein was evaluated according to AOAC 984.13 method. Lipid was measured using AOAC 960.39 method. Ash was quantified by AOAC 930.30 method. Insoluble dietary fiber (IDF), soluble dietary fiber (SDF) and total dietary fiber (TDF) were measured by AOAC 985.29 method. Starch was estimated using AOAC 996.11 method. Results were expressed in g per 100 g on dry basis (db).

Determination of total phenolic content and antioxidant capacity

Wheat flour, AHP and crushed crackers were extracted with acidified methanol (the volume ratio of methanol/HCl/water was 80/1/20) at 30oC for 1 h. The material/solvent ratio was 1/15 (w/v). The extract was separated from the residue by centrifugation at 1,600×g for 20 min (3K30, Sigma Zentrifugen Ltd., Osterodeam Harz, Germany). The total phenolic content in the obtained extract was determined with the spectrophotometric method and Folin-Ciocalteau reagent [Agbor et al., 2014]. Briefly, 0.2 mL of the extract and 1 mL of the Folin-Ciocalteu reagent were mixed by vortexing for 30 s. The reaction mixture was left at room temperature in the dark for 2 h, and the absorbance was recorded at 760 nm (UV 2600i spectrophotometer, Shimadzu Co., Kyoto, Japan). Total phenolic content was presented as mg gallic acid equivalent per g of the sample dry basis (mg GAE/g db). Antioxidant capacities were evaluated using ferric-reducing antioxidant power (FRAP) and 2,2-diphenyl-1-picrylhydrazyl (DPPH) assays [Benzie & Strain, 1999; Brand-Williams et al., 1995]. For DPPH assay, 0.1 mL of the diluted extract was added into 3.9 mL of a 60 μM DPPH radical solution in methanol. The reaction mixture was incubated in the dark at room temperature. The absorbance at 515 nm was monitored at 0 and after 30 min of incubation using methanol as the blank.

For FRAP assay, 3.8 mL of the FRAP working solution (25 mL of 0.3 M acetate buffer pH 3.6, 2.5 mL of 10 mM 2,4,6-tris(2-pyridyl)-s-triazine solution in 40 mM HCl, and 2.5 mL of 20 mM FeCl3×6H2O) were mixed with 0.2 mL of the diluted extract. The reaction mixture was incubated in the dark at 37°C for 5 min, the absorbance at 593 nm was measured with an acidified methanol as the blank. For both assays, the antioxidant capacity was expressed as μmol Trolox equivalent per g of the sample dry basis (μmol TE/g db).

Physical analysis

Water holding capacity and oil holding capacity of AHP and wheat flour were measured following the procedure described by Fernández-López et al. [2009]. About 3 g of the sample were mixed with 30 mL of water or soybean oil (Tuong An Vegetable Oil Joint Stock Company, Ba Ria-Vung Tau Province, Vietnam) by vortexing for 30 s. After 2 h, the mixture was centrifuged at 1,000×g for 20 min. The supernatant was then decanted. The absorbed water or oil was determined by the difference between the sediment and the initial sample weight. Results were expressed as g of water or oil per g of the sample dry basis.

Hardness was evaluated using a texture profile analyzer (TAXT Plus, Stable Micro System, Godalming, UK) and 3-point break measurement. Thickness and diameter of cracker samples were measured using a vernier caliper; the thickness was evaluated by measuring the height of a stack of six crackers and dividing by six, while the diameter was determined by measuring the width of six crackers placed edge to edge and dividing by six [Park et al., 2015]. Instrumental color analysis was performed using a colorimeter (CM-3700A, Konica Minolta, Japan) in the CIELab color space; L* (lightness), a* (redness-greenness) and b* (yellowness-blueness) values were recorded. Total color difference of the cracker samples (ΔE) was computed by the following formula (1):

where: L*0, a*0 and b*0 are the color values of the crackers without AHP addition; L*, a*, and b* are the color values of the AHP- -supplemented crackers.Sensory evaluation

Sensory overall acceptability of all cracker samples was evaluated with an acceptance test and a 9-point hedonic scale. The participants gave scores 1–9 to the cracker samples, ranging from “extremely dislike” to “extremely like” [Mai et al., 2022]. Sixty-two untrained participants were chosen from academic staff and students of the Ho Chi Minh City University of Technology.

Statistical analysis

All cracker samples were done in triplicates to calculate the average result. Results were presented as mean and standard deviation. One-way analysis of variance was conducted using Statgraphics Centurion XV.I software, and the significance of differences was compared with Duncan’s multiple range test (p<0.05).

RESULTS AND DISCUSSION

Chemical composition, antioxidant capacities and physical characteristics of asparagus hard-stem powder and wheat flour

The chemical composition, antioxidant capacities and physical characteristics of AHP and wheat flour are illustrated in Table 1. The lipid and starch contents of AHP were 1.4 and 34.1 times, respectively, lower than those of the wheat flour, while the by- -product contained 1.1 and 8.0 times more protein and ash, respectively. The amounts of IDF, SDF, and TDF of AHP were 27.9, 2.0, and 15.3 times greater, respectively, than those of the wheat flour. The dietary fiber contents of asparagus hard-stems in the present research were nearly similar to those reported by Iwassa et al. [2019] (57.18 g/100 g db), but they were higher than the findings of de Paula Laidens et al. [2021] (47.86 g/100 g db) probably due to the difference in asparagus varieties, cultivation and harvesting conditions.

Table 1

Chemical composition, antioxidant capacities and physical characteristics of asparagus hard-stem powder and wheat flour.

[i] Each value is expressed as mean ± standard deviation (n=3) and means having different letter superscripts within the same row are significantly different (p<0.05); TDF, total dietary fiber; SDF, soluble dietary fiber; IDF, insoluble dietary fiber; GAE, gallic acid equivalent; TE, Trolox equivalent; L*, lightness; a*, redness–greenness; b*, yellowness–blueness; ΔE, total color difference; db, dry basis.

The AHP contained 5.5 times more total phenolics than the wheat flour (Table 1). Additionally, the antioxidant capacities of AHP measured by FRAP and DPPH assays were 47.2 and 18.4 times, respectively, greater than those of wheat flour. Asparagus hard-stems are reported to contain rutin, quercetin, kaempferol and other polyphenols and they exhibit high antioxidant activity [Guo et al., 2020].

According to the instrumental color analysis, the AHP was darker than the wheat flour as indicated by a higher L* value (Table 1). Additionally, the AHP had higher a* and b* values than the wheat flour, indicating that the yellowness and redness of AHP were more intense. Besides, the water holding capacity and oil holding capacity of wheat flour were approximately 5.1 and 3.0 times, respectively, lower than those of AHP. Water holding capacity may be related to SDF content since this fiber group has an ability to retain water. Oil holding capacity is associated with a chemical structure of plant polysaccharides and proteins; it is influenced by surface properties and hydrophobic nature of fiber particles [Fernández-López et al., 2009].

Based on the chemical composition and physical characteristics, the supplementation of AHP to cracker recipe was expected to enhance dietary fiber and antioxidant contents of the fortified crackers; however, the use of AHP could affect their textural and sensory quality.

Impacts of various ratios of asparagus hard-stem powder on the cracker quality

Impacts on the nutritional composition and antioxidant capacities of crackers

Table 2 presents nutritional composition and antioxidant capacities of the cracker samples. The supplementation of AHP to cracker formula improved the contents of protein, ash, and dietary fiber whilst the lipid and starch contents of the fortified crackers were significantly reduced. This observation was attributable to the difference in the chemical composition between AHP and wheat flour. Specifically, the 20% AHP added crackers contained 5.0, 5.3 and 3.8 times more TDF, IDF and SDF, respectively, than the control crackers. A similar increase in dietary fiber content was previously reported when 5–15% chickpea husk was supplemented to the cracker formula [Bose & Shams-UdDin, 2010]. It can be noted that when the ratio of AHP was 15% or greater, the fortified crackers were considered as food with a high fiber content according to the Food and Agriculture Organization since the TDF content was higher than 6% [FAO, 1997]. Nevertheless, high AHP level in the recipe enhanced the IDF/SDF ratio of the fortified crackers. The appropriate ratio of IDF/SDF should be about 3/1 for food products since IDF and SDF exert different health effects on human [Rodríguez Galdón et al., 2009].

Table 2

Nutritional composition, total phenolic content and antioxidant capacities of crackers supplemented with various ratios of asparagus hard-stem powder (0–20% of flour blend).

[i] Each value is expressed as mean ± standard deviation (n=3) and means having different letter superscripts within the same row are significantly different (p<0.05); TDF, total dietary fiber; SDF, soluble dietary fiber; IDF, insoluble dietary fiber; GAE, gallic acid equivalent; TE, Trolox equivalent; db, dry basis.

Additionally, a crucial improvement was found in the total phenolic content and antioxidant capacities of the fortified crackers (Table 2) due to the greater amount of phenolics in AHP compared to that in wheat flour. At 20% AHP level, the total phenolic content of the fortified crackers was increased 3.1 by times while their FRAP and DPPH radical scavenging capacity were improved by 6.1 and 1.8 times, respectively as compared to those of the control crackers.

Impacts on the physical attributes and overall acceptability of crackers

The augmentation of the AHP ratio in the cracker formulation from 0 to 20% enhanced the product diameter by 9% while decreased its thickness by 27% (Table 3). This can be explained by the reduced gluten content of the cracker dough. Moreover, asparagus hard-stem proteins are poor in cysteine and methionine [Guan et al., 2015], resulting in a weak gluten network [Gambuś et al., 2011] when the AHP addition ratio was increased. A similar trend was recorded when the powder of old stalks of asparagus was supplemented to biscuit products [Liu et al., 2016].

Table 3

Physical attributes and overall acceptability of crackers supplemented with different ratios of asparagus hard-stem powder (0–20% of flour blend).

[i] Each value is expressed as mean ± standard deviation (n=62 for sensory score and n=3 for other characteristics); means having different letter superscripts within the same row are significantly different (p<0.05); L*, lightness; a*, redness–greenness; b*, yellowness–blueness; ΔE, total color difference.

As the incorporation ratio of AHP was enhanced from 0 to 20%, the cracker hardness was doubly increased (Table 2). Lee et al. [2022] recently claimed an increase in cracker hardness when supplementing red ginseng marc from 0 to 20% to the product formulation and explained that it was due to the enhancement in dietary fiber content. The greater the dietary fiber content in food was, the greater was food hardness [Damat et al., 2019].

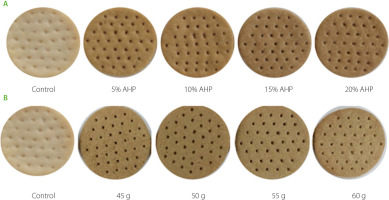

The use of AHP also enhanced darkness of the cracker samples as well as their redness and yellowness (Table 2), since the color of AHP and wheat flour greatly varied. The ΔE values of all fortified crackers were higher than 5, indicating their color difference as compared to that of the control crackers. The appearance of the crackers, shown in Figure 1A, confirmed an increase in darkness of the crackers as the AHP ratio was enhanced in the product recipe. A similar increase in product darkness was also observed when asparagus spear powder was supplemented to the pasta formulation [Vital et al., 2020].

Figure 1

Pictures of crackers (A) fortified with 5, 10, 15 and 20% asparagus hard-stem powder (AHP), the water amount in cracker recipe was fixed at 45 g per 100 g the flour blend; and crackers (B) fortified with 20% AHP, the water amount was 45, 50, 55 and 60 g per 100 g the flour bend. The controls were crackers without AHP and the water amount of 45 g per 100 g wheat flour.

The increased AHP ratio in the cracker formulation successively decreased the overall acceptability of the fortified crackers (Table 2) mainly due to their enhanced hardness. The control crackers received the highest sensory score. The sensory scores of the 5, 10 and 15% AHP-added crackers can be considered acceptable; however, the sensory score of the crackers with 20% AHP was lower than 5, indicating that this sample was not accepted by consumers.

Generally, a high AHP ratio in the cracker recipe improved dietary fiber and phenolic contents, as well as antioxidant capacity of the fortified crackers, but increased their hardness and decreased their sensory quality. The presence of AHP with high water holding capacity in the cracker dough resulted in a reduced amount of free water for gluten network development during the cracker kneading. The effects of water amounts used in the recipe of 20% AHP-added crackers needed to be clarified to improve their texture and sensory quality.

Effects of water amounts used in the high-fiber cracker recipe on the quality of 20% AHP-fortified crackers

When the water amount used in the high-fiber cracker recipe was enhanced from 45 to 60 g/100 g the flour blend, the product hardness was reduced by 2.5 times (Table 4). This reduction can be explained by a better development of a gluten network during the kneading of high-fiber dough when the water content was increased. The gluten network accounts for dough elasticity, resulting in crackers with low hardness [Beverly, 2014]. However, so high water level in dough interferes with the gluten structure and makes the dough difficult to hold its shape [HadiNezhad & Butler, 2009]. At water level of 60 g/100 g the flour blend, the hardness of high-fiber crackers was about 1.3 times lesser than that of the control crackers (Table 4).

Table 4

Physical attributes and sensory scores of crackers fortified with 20% asparagus hard-stem powder (AHP) and kneaded with different amounts of water.

[i] Each value is expressed as mean ± standard deviation (n=62 for sensory score and n=3 for other characteristics); means having different letter superscripts within the same row are significantly different (p<0.05); Control crackers were made from wheat flour without AHP and the water amount in the recipe of 45 g/100 g wheat flour; L*, lightness; a*, redness–greenness; b*, yellowness–blueness; ΔE, total color difference.

The diameter of 20% AHP-fortified crackers was slightly reduced towards the value of the control crackers as the water amount in the product recipe changed from 45 to 60 g/100 g the flour blend (Table 4). For thickness, this attribute was improved and achieved the highest value at the water amount of 55 g/100 g of the flour blend. A higher water level decreased the product thickness since the dough became flabby [Hoseney & Rogers, 1990].

The increase in water amount used in the cracker formulation from 45 to 60 g/100 g the flour blend slightly reduced L* value of the product color (p<0.05) (Table 4) probably due to improved Maillard reactions. However, all L*, a* and b* values were changed in narrow ranges. Figure 1B shows that the change in the water level in the cracker recipe did not strongly affect the color of the fortified crackers.

It can be noted that the acceptance level of high-fiber crackers was successively increased from 4.3 to 6.6 points (out of 9) when the water content was increased from 45 to 55 g/100 g the flour blend (Table 4) due to a reduced hardness. At water level of 55 and 60 g/100 g the flour blend, the overall acceptability of the crackers did not differ significantly (p≥0.05). Generally, the recommended water level was 55 g/100 g the flour blend for the 20% AHP-added cracker recipe; and a change in the water level used in high-fiber cracker making was a potential technique to improve hardness and sensory quality of the product.

CONCLUSIONS

AHP was proved to be an ingredient with a high dietary fiber content and antioxidant capacities. The increment in the AHP ratio in the cracker formulation from 0 to 20% increased the total dietary fiber and phenolic content and antioxidant capacities of the fortified crackers. However, the increased ratio of AHP in the cracker recipe significantly enhanced the product hardness while reduced its thickness and sensory score. The appropriate AHP ratio was 15% since the fortified crackers were deemed high-fiber food and accepted by consumers. Change in the water level in the recipe of high-fiber crackers successfully reduced the hardness and improved the sensory score of high- -fiber crackers. When the AHP addition ratio was increased to 20%, the recommended water level was 55 g/100 g the flour to improve its textural and sensory quality. AHP can therefore, be considered a potential ingredient of dietary fiber and antioxidants for fortification of cracker products.