INTRODUCTION

Hydrocolloids were widely applied in food processing as thickeners, gelling agents, structure stabilizers, and emulsifiers [Williams & Phillips, 2000]. During the drying process, particularly for fruit puree or juice, hydrocolloids were added to improve both product quality and drying efficiency. Previous studies applied hydrocolloids to fruit pulp before processing to prevent the stickiness and caking phenomena [Bhandari et al., 1993; Gómez-Pérez et al., 2020; Singh Gujral & Singh Brar, 2003]. After mixing hydrocolloids into the pulp, the glass transition temperature of fruit pulp increased, leading to the drying process being implemented easily and obtaining high-quality products [Bhandari et al., 1993]. It was reported that the increase of maltodextrin (MD) could improve the sensory quality of mango leather [Singh Gujral & Singh Brar, 2003] as well as the lamina and texture properties of murta (Ugni molinae Turcz) berry leather [Gómez-Pérez et al., 2020], and enhance the quality of dried fruit powder from tomato pulp [Goula & Adamopoulos, 2008], blackberry [Ferrari et al., 2012], etc. Among hydrocolloids, MD was the most popular carrier used in food production [Williams & Phillips, 2000].

Drying technology continues to play an important role in food preservation and processing. The commercial and utilitarian worth of food items was increased as a result of the removal of moisture from their constituents. Among the fruit forms that can be dried, fruit juice and puree get the most attention when it comes to making fruit powder, which is simple to utilise or formulate commercial food goods [Ramaswamy & Marcotte, 2005]. In the research, spray-, drum-, and freeze-drying were the most common methods for producing fruit powder. There were, however, disadvantages to each drying procedure. In spray drying, the powder quality was diminished as a result of the addition of 40 to 60% of carriers [Brennan et al., 1971; Can Karaca et al., 2016; Sobulska & Zbicinski, 2021]. In turn, drum drying at temperatures ranging from 120 to 170°C caused substantial harm to the quality of dried materials [Nindo & Tang, 2007]. Finally, the freeze-drying exclusively produced fruit powder of the highest grade [Ratti, 2013], but the adoption and maintenance of this process were costly.

Recent advancements in drying technology would increase the likelihood of discovering viable drying methods to address pre-existing issues. Recently, refractance window (RWTM) drying has received increased interest in the dehydration of fruit purees or slices [Vega-Mercado et al., 2001]. In the RWTM drying technique, moisture diffusion and evaporation occur rapidly due to heat conduction, convection, and radiation at the hot-water interface and air-film interface [Raghavi et al., 2018]. Therefore, the drying process could be finished quickly and preserve the quality of the dried product efficiently. Compared to the above-mentioned drying processes, RWTM drying was addressed in fewer publications; however, the RWTM drying results were substantially more outstanding. In the literature, the RWTM drying was reported to produce good nutritional and sensory quality of dried fruits and vegetables such as carrots, strawberries [Nindo & Tang, 2007], tomatoes [Abul-Fadl & Ghanem, 2011], mango pulp [Caparino et al., 2012], pomegranate leather [Tontul & Topuz, 2017], cornelian cherry pulp [Tontul et al., 2018], low-fat avocado paste [Da Silva & Da Silva, 2018], apple slices [Rajoriya et al., 2019], goldenberry pulp [Puente et al., 2020], etc. Besides, the RWTM drying was more thermally efficient than convective and freeze-drying [Nindo & Tang, 2007]. Thus, RWTM drying was anticipated to be an effective method for drying fruits and vegetables. However, additional evidence is required to confirm this notion.

Avocado fruits are nutrient- and phytochemical-dense superfoods [Comerford et al., 2016]. Specifically, bioactive substances with varied medicinal capabilities in avocado have been shown to be associated with consumer health advantages [Lye et al., 2020]. As a result of its climacteric fruit qualities and significant processing constraints, avocado’s economic and utilitarian worth decreased.

In this situation, applying the drying process to avocado would be one of the appropriate alternatives. The avocado’s shelf life might be prolonged and new avocado-based products could be developed after drying. In previous studies, avocado was reported to be dried by heat-pump [Ceylan et al., 2007], freeze-drying [Castañeda-Saucedo et al., 2014; Rafidah et al., 2014; Souza et al., 2015], hot-air drying [Temu, 2013], and superheated-steam drying [Rafidah et al., 2014]. However, these drying methods took a long operating time (varying from 3 to more than 20 h). A recent report indicated that the RWTM drying temperature greatly affected drying kinetics and avocado pulp quality [Nguyen, et al., 2022b]. The high RWTM drying temperature of 90°C could preserve over 80% of total phenolics and antioxidant activity [Nguyen, et al., 2022b]. It appeared that the RW had a good potential for the manufacturing of avocado fruit powder. While the effect of drying temperature has been well explored, the influence of maltodextrin content has not yet been investigated. Therefore, this study sought to determine the effects of MD content on the drying rate and quality of powder (including total contents of phenolics and chlorophylls, antioxidant capacity, and color parameters) made of avocado pulp dried with the RWTM technique.

MATERIALS AND METHODS

Materials and chemicals

Fresh avocado (Persea americana Mill. cv. ‘Maluma’) fruits were obtained from a local farm in DakLak, Vietnam; only ripe avocados with a green exterior were selected.

Gallic acid, 2,4,6-tripyridyl-s-triazine (TPTZ), 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical, and 6-hydroxy-2,5,7,8 tetramethylchromane-2-carboxylic acid (Trolox) were purchased from Sigma-Aldrich (Merck PTE Ltd, Ascent Building, Singapore). The solid sodium tungstate, sodium molybdate, and lithium sulphate were constituents of the Folin-Ciocalteu (2 N) reagent. Maltodextrin (dextrose equivalent in the range of 16.5–19.5, Sigma-Aldrich) was acquired from a local vendor. As well as other chemicals, acetic acid, sodium acetate, chloroform, sodium carbonate, methanol, acetone, diethyl ether, and ferric chloride hexahydrate were of analytical quality.

Avocado pulp preparations

After receiving, the avocado fruits were washed, peeled, devoid of seed, and sliced into slices with 3.00±0.03 mm thickness. Then, the slices were soaked in a sodium bicarbonate solution (0.05%) for 30 min and subjected to steam blanching for 3 min to inactivate the browning enzymes and inhibit other enzymes in materials. Subsequently, the blanched samples were cooled promptly with cold water at 5.0±0.5°C and ground to collect avocado pulp using a commercial blender (BJY-CB2L60-A, Berjaya Steel Product Sdn Bhd, Kuala Lumpur, Malaysia). To prepare the material for drying, the pulp was mixed with MD using a laboratory mixing overhead stirrer (SH-II-6C, Hebei, China). The mix was analyzed for total phenolic content (TPC), total chlorophyll content, antioxidant capacity, and color parameters before drying.

Drying conditions and drying rate determination

This study designed experiments with three replications using the one-factor-at-a-time approach. The samples were prepared using a block design that was randomly generated. Each sample containing 100 g of pulp was mixed with different amounts of MD, i.e. 0, 6, 7.5, 9, and 10.5 g. In this investigation, a custom-built refractance window (RWTM) drying apparatus comprised of a hot water reservoir (0.42×0.28×0.10 m) and a thermostatically-controlled water bath was operated in a batch laboratory-scale configuration (Model DH.WB000106, Daihan-Scientific, Wonju-si, South Korea). A polyester film (MylarTM, Jiangsu, China) with a thickness of 0.25 mm was utilized to transfer heat from hot water to fruit pulp placed in 2 mm-thick layers atop the Mylar films. Our earlier research determined that the RWTM drying temperature had a substantial effect on the quality of dried avocado powder, with the highest quality powder being produced at 90°C [Nguyen, et al., 2022b]. Therefore, each sample was dried at 90°C using RWTM drying.

The moisture content of samples was measured using the moisture analyzer (MB23, Ohaus, Parsippany, NJ, USA) in 5-min intervals. The drying process was stopped when the moisture content reached approximately 0.04 g/g dry weight (DW) because this moisture content assured that dried avocado could be ground to powder. The drying rate (g/g DW) was computed from Equation (1).

where: Mt, and Mt+Δt were the moisture content at drying time t (min), and t+Δt (min), respectively.Then, the avocado powder was used to analyze TPC, total chlorophyll content, antioxidant capacity, and color parameters.

Preparation of avocado extracts for chemical analysis

The extracts were obtained according to the procedure reported in the literature [Wang et al., 2010]. The fresh pulps as well as dried and powdered avocado pulps with and without MD (0.2 g) were extracted using 10 mL of solvent (7 mL acetone + 0.03 mL glacial acetic acid + 2.97 mL water). Then, the extracts were diluted to 25 mL and analyzed for their TPC and antioxidant capacity.

Total phenolic content determination

The method with Folin-Ciocalteu reagent, as established in ISO 14502-1:2005, was deployed to measure the TPC with distilled water serving as a blank [ISO, 2005]. The UV-9000 spectrophotometer (Metash, Shanghai, China) was used for absorbance measurement. The gallic acid calibration curve was used to calculate the total phenolic content, which was given as mg of gallic acid equivalent per g of dry weight (mg GAE/g DW). The retention percentage of TPC was determined according to Equation (2).

where: CTPC, before drying and CTPC, after drying were the TPC in the sample before drying and after drying, respectively.DPPH radical scavenging assay (DPPH)

The DPPH radical scavenging activity of the extract was determined according to the procedure described previously [Nguyen et al., 2022b] using a UV-9000 spectrophotometer (Metash). DPPH radical scavenging activity was analyzed using the standard curve for Trolox plotted as the percent of scavenged DPPH radicals vs. concentration. Results were expressed as mg Trolox equivalent per g of sample dry weight (mg TE/g DW). The retention percentage of DPPH radical scavenging activity was calculated from Equation (3).

where: CDPPH, before drying and CDPPH, after drying were the DPPH radical scavenging activity of the sample before drying and after drying, respectively.Ferric reducing antioxidant power determination

The ferric reducing antioxidant power (FRAP) assay was conducted in accordance with a modified version of the method described in the literature [Benzie & Strain, 1996]. The acetate buffer (0.3 M, pH 3.6), TPTZ (10 mM in 40 mM HCl), and FeCl3×6H2O (20 mM) were mixed in a 10:1:1 (v/v/v) ratio to make the reagent. In order to measure the FRAP, 2.85 mL of FRAP reagent was applied to 0.15 mL of diluted sample. The reaction mixture was incubated in the dark for 30 min, after which the absorbance was measured at 593 nm with a UV-9000 spectrophotometer (Metash) using distilled water as the blank. Based on the Trolox calibration curve, the ferric reducing antioxidant power was computed and reported as mg Trolox equivalent per g of sample dry weight (mg TE/g DW).

The retention percentage of FRAP was calculated from Equation (4).

where: CFRAP, before drying and CFRAP, after drying were the FRAP of the sample before drying and after drying, respectively.Determination of total chlorophyll content

In order to initiate the extraction process, 0.2 g of avocado pulps or powders was combined with 5 mL of the solvent (chloroform and methanol, 2:1, v/v) and vortexed for 30 s at 2,000 rpm. After sonication (40 KHz, 240 W, 5 min), the sample was vortexed again for 10 s and cooled at 4°C for 20 min. After cooling the sample, it was centrifuged at 2,095×g for 10 min, and the supernatant was collected. The solvent in the supernatant was evaporated in a Petri dish using an LO-FS100 forced convection oven (LK Lab, Namyangju, Korea) at 50°C for 30 min, and residue was redissolved in 10 mL of pure diethyl ether for analysis of total chlorophyll content as described in the literature [Lichtenthaler & Buschmann, 2001]. Results were calculated according to Equation (5).

where: A661 and A642 corresponded to absorbances measured at 661 and 642 nm using a UV-9000 spectrophotometer (Metash), msample (DW) was the dry weight of sample.The retention percentage of total chlorophyll content was calculated from Equation (6).

where: CChlorophyll, before drying and CChlorophyll, after drying were the total chlorophyll content in the sample before drying and after drying, respectively.Determination of color parameters

Color of avocado pulps and powders was assessed using the NR110 precision colorimeter (Shenzhen ThreeNH Technology Co. Ltd, Shenzhen, China) in the CIELab color scale. The L*, a*, and b* values were measured. L* symbolizes lightness on a scale ranging from 0 (black) to 100 (white). Positives and negatives of a* represent red and green, whereas positives and negatives of b* represent yellow and blue. Besides, the total color difference (ΔE) was calculated according Equation (7) to evaluate the difference in total color between the tested samples.

Statistical analysis

Experimental data were evaluated utilizing the SPSS 15 programme (SPSS Inc., Chicago, IL, USA). The significant differences in mean values between the samples were determined using one-way analysis of variance (ANOVA) with Tukey’s multiple range test at the 5% significance level for all experiments, which were carried out in triplicate.

RESULTS AND DISCUSSION

Effect of maltodextrin addition on the drying rate

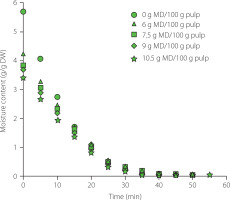

The curves of moisture content versus drying time of avocado pulp at different maltodextrin (MD) contents are presented in Figure 1. In addition, the drying curves are shown in Figure 2. The pulps with a higher content of MD had a lower drying rate and a longer drying time. The control sample (0 g MD/100 g of pulp) had the highest drying rate and the shortest drying time. The MD with a moisture content of 3.62±0.04 g/100 g (wet basis) was added to the avocado pulp. Therefore, the increased addition of MD would rise significantly dry matter content of the pulp before drying. According to Rodosta & Schierbaum’s [1990] findings, the presence of MD in avocado pulp would create hydrogen bonds with free water molecules. This could cause internal and external diffusion resistance, leading to limited moisture removal from the pulp in the drying process [Goula & Adamopoulos, 2008]. Consequently, the initial drying rate was slower at higher MD content. Some previous studies on the MD effect on drying kinetics of sugar, acid-rich foods [Adhikari et al., 2004], pineapple, and mango leather [Gujral et al., 2013] showed similar findings.

Figure 1

The curves of moisture content versus drying time of avocado pulp without (0 g/100 g pulp) and with the addition of 6, 7.5, 9, and 10.5 g maltodextrin (MD/100 g of pulp) dried by refractance window technique. DW, dry weight.

Figure 2

Drying rate curves of avocado pulp without (A) and with the addition of 6 g (B), 7.5 g (C), 9 g (D) and 10.5 g (E) maltodextrin per 100 g of pulp dried by refractance window technique. DW, dry weight.

Figure 2 further revealed that moisture removal only occurred during the falling-rate period for all samples. It is likely that during the RWTM drying process with a thin layer of avocado pulp, moisture evaporated rapidly, causing the drying process to occur during the falling-rate period without a constant drying rate period. This finding was consistent with literature data on RWTM drying [Abul-Fadl & Ghanem, 2011; Gómez-Pérez et al., 2020; Nguyen, et al., 2022b; Nindo & Tang, 2007; Ochoa-Martínez et al., 2012].

Drying curves of avocado pulps without and with different contents of MD show that the behavior of moisture removal was significantly different between samples at the moisture content higher than 1.0 g/g DW (Figure 2). When the moisture content of the drying material was above this value, the moisture diffusion was directly related to the elimination of free water. When the moisture content was below 1.0 g/g DW, the moisture removal predominantly eliminated bound water. Therefore, when MD was mixed with avocado pulp, the MD predominantly interacted with the free water. Consequently, the MD had a substantial impact on the drying rate curves of avocado pulp with a moisture content greater than 1.0 g/g DW.

Effect of maltodextrin addition on total contents of phenolics and chlorophylls

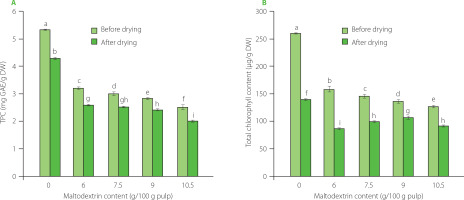

The TPC and total chlorophyll content of the avocado pulps without and with different MD contents and powders obtained by RWTM drying of pulps are shown in Figure 3. The addition of MD to fresh pulp significantly (p<0.05) decreased its TPC and total chlorophyll content and these decreases were dependent on the MD content. The results of phytochemical content analysis were expressed based on dry weight of pulp or powder. Therefore, an increase in MD content would increase the dry matter content of the pulp, resulting in a decrease in the avocado pulp’s TPC and total chlorophyll content prior to drying.

Figure 3

Total phenolic content, TPC (A) and total chlorophyll content (B) in avocado pulps without and with the addition of maltodextrin, as well as in their powders obtained by refractance window drying. Values with the same letters are not significantly different (p≥0.05). GAE, gallic acid equivalent; DW, dry weight.

The TPC and total chlorophyll content in the samples before drying were significantly (p<0.05) higher than in powders after drying (Figure 3), thus the total content of both phenolics and chlorophylls deteriorated during the RWTM drying of the avocado pulp with MD content increasing from 0 to 9 g MD/100 g of pulp; however, phytochemical retentions during the RWTM drying increased (Table 1). The highest retentions (85.60% for TPC, and 78.78% for chlorophylls) were found with the addition of 9 g MD/100 g of pulp, although the TPC retention for the pulp with 7.5 g MD/100 g was not significantly (p≥0.05) different. When the highest level of MD additive was used (10.5 g MD/100 g of pulp), the retentions of TPC and total chlorophyll content decreased significantly (p<0.05). The enhanced retentions of TPC and chlorophylls by increasing the pulp’s MD content may be because MD acted as the coating substance that produces a physical barrier [Osorio et al., 2011], restricting the contact of phytochemicals with external factors like oxygen. Therefore, the rate of phytochemical degradation was slowed, and their retention was increased. As stated previously, MD in pulp increased the dry weight and formed bonds with free water [Radosta & Schierbaum, 1990]. Consequently, a larger content of MD would diminish water activity, resulting in decreased enzyme activity that contributes to the retention of phenolics and chlorophylls. Studies on the impact of MD on the drying of pulp/puree have recently mostly concentrated on the assessment of the drying rate and physical characteristics of dried samples. Regarding to the effect of MD on the quality of the dried material, Ahmed et al. [2009] observed that after hot-air drying, MD was positively linked with the phenolic content in purple sweet potato flour. Furthermore, compared to the avocado pulp without MD, the addition of MD allowed to retain higher TPC after infrared radiation drying [Nguyen et al., 2021].

Table 1

The retention of total phenolic content (TPC), total chlorophyll content, and antioxidant capacity in avocado powder obtained from pulp without and with the addition of maltodextrin (MD) by refractance window drying.

However, when 10.5 g MD/100 g of pulp was utilized, the preservation of phenolics and chlorophylls in pulp decreased. In the drying process, the operating time was also the reaction time [Nguyen et al., 2020]. Therefore, RWTM drying of avocado pulp with 10.5 g MD required the longest drying time, resulting in greater phytohemcial loss.

Effect of maltodextrin addition on antioxidant capacity

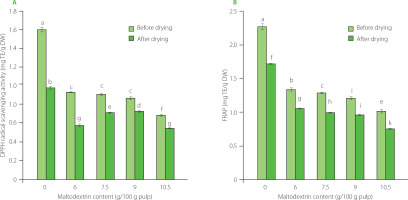

The antioxidant capacity of avocado pulps without and with MD and powders after RWTM drying was determined as DPPH radical scavenging activity and as FRAP. Results are reported in Figure 4. Additionally, the results of antioxidant capacity retention after drying are shown in Table 1. Similarly to the total content of phenolics and chlorophylls, the antioxidant capacity tended to decrease as increasing amounts of MD were added to fresh pulp. Significantly (p<0.05) lower values for powders compared to pulps before drying were also noted. Moreover, the effect of MD addition level to pulp on retention of DPPH radical scavenging activity after RWTM drying was similar as on retention of phytochemical contents. The content of 9 g MD/100 g of pulp allowed to retain the highest DPPH radical scavenging activity after drying. In the case of FRAP, when MD content was in the range of 6 to 9 g/100 g of pulp, the differences in retention were insignificant (p≥0.05). Furthermore, the samples with MD additions ranging from 6 to 9 g/100 g of pulp retained more FRAP than those without MD or with 10.5 g MD/100 g of pulp (p<0.05).

Figure 4

DPPH radical scavenging activity (A) and ferric reducing antioxidant power, FRAP (B) of avocado pulps without and with the addition of maltodextrin, as well as in their powders obtained by refractance window drying. Values with the same letters are not significantly different (p≥0.05). TE, Trolox equivalent; DW, dry weight.

According to a previous report, the phenolics and chlorophylls identified in avocados are responsible for their antioxidant potential, but the contribution of the former is definitely greater than the latter [Wang et al., 2010]. In addition, avocado pulp may contain other antioxidants, such as ascorbic acid and carotenoids [Lye et al., 2020]. In our study, the trend of DPPH radical scavenging activity differentiation between samples was comparable to the variations of TPC and total chlorophyll content. According to the evidence, both phenolics and chlorophylls may have contributed to DPPH radical scavenging activity of pulps and powders. However, TPC, chlorophylls, and other antioxidants in avocado may affect FRAP.

Effect of maltodextrin addition on color parameters

The color of avocado pulp changed significantly after RWTM drying (Table 2). Specifically, the L* and b* values of the color of the powders decreased, whereas the a* value increased compared to the color of the fresh pulp. The results indicated that the samples became darker, more yellow, and less green. When MD content changed from 0 to 7.5 g/100 g of pulp, the L* value in dried samples gradually increased, while the a* and b* values did not change significantly (p≥0.05). The color of powder obtained from pulp with 9 g MD/100 g of pulp had the greatest greenness, as well as the lowest total color difference value. The highest addition of MD to the pulp caused the greatest color change with a ∆E value of 12.38.

Table 2

Color parameters of avocado pulp and powders obtained from pulp without and with the addition of maltodextrin (MD) by refractance window drying.

The color played a key role in the customer’s buying choice; therefore, this criterion retains its important significance. In processing and preservation, color was also used to assess processing efficiency because it correlates with the quality change of items. Pigment loss, oxidation, enzymatic or non-enzymatic browning, etc., accounted for the majority of the color change during the drying process [Bahloul et al., 2009]. In our study, the decrease of L* may have been due to browning reactions occurring during drying. With regard to a* values, a rise in a* indicated that the dried samples were less green. For green-pigmented foods like avocado, the biotransformation of chlorophylls to pheophytins, with the replacement of magnesium with hydrogen, was primarily responsible for the loss of greenness [Rudra et al., 2008]. In addition, according to the literature, MD could decrease the browning index value [Caliskan & Dirim, 2016] and increase the L* value of dried product [Nguyen et al., 2022a].

CONCLUSIONS

The addition of MD dramatically altered the behavior of moisture removal and the quality of avocado pulp and powder obtained by RWTM drying. The increase in MD content decreased the drying rate and the initial TPC, total chlorophyll content and antioxidant capacity of pulp but had a beneficial effect on the retention of these phytochemicals, bioactivity and color of the powders. The most effective in protecting functional properties and bioactive compounds of powders was the addition of 9 g MD/100 g of pulp. Although a higher MD content in pulp could increase the quality of drying products, too much MD led to a slower drying rate, which resulted in a longer drying time and greater product damage. Overall, this study demonstrated the RWTM drying technique had great potential for the production of avocado powder with high-quality retention if the appropriate amount of MD was added prior to drying. These findings could be implemented for the manufacturing of fruit powder. To produce the highest quality fruit powder, additional research should concentrate on identifying optimal drying conditions or assessing alternative creative drying procedures.