INTRODUCTION

A balanced diet helps prevent malnutrition and certain diseases. Every day, people need food with sufficient energy content and fundamental nutrients including carbohydrates, protein, lipid, vitamins, and minerals [Stipanuk, 2019]. In addition, bioactive compounds are also important for daily diet since they have positive effects on human health. Nowadays, healthy food products have attracted great attention from consumers due to their different health-beneficial components [Bianchi et al., 2021], such as dietary fiber and antioxidants.

The addition of dietary fiber and antioxidants to the formulation of conventional foods is a current trend in the development of healthy food products. According to Maphosa & Jideani [2016], increased consumption of dietary fiber improves the glucose and lipid metabolism as well as gut microbiota status, leading to the promotion of normal laxation and protective functions against colonic disorders and pathogens. Moreover, a high-fiber diet supports the treatment of eating disorders, diabetes, obesity, certain types of heart disease, and cancer. The recommended daily intake of dietary fiber should be about 35 g for an adult [Maphosa & Jideani, 2016]. Besides, antioxidants from foods can prevent or slow down oxidative damage of cell molecules by scavenging free radicals in human body. A diet rich in antioxidants may reduce the risk of various diseases including diabetes, cardiovascular diseases, inflammation, dementia, and various types of cancer, such as esophagus, stomach, and colon cancer [Tan et al., 2018].

Pasta is widely selected for fiber and antioxidant fortification since it is an element of everyday diet in many countries and is poor in these components [Bianchi et al., 2021]. Dietary fiber and antioxidants from many sources have been added to pasta recipes, such as whole cereal grain flours [Aravind et al., 2012], powder from fruits [Bustos et al., 2019], legumes [Wójtowicz & Mościcki, 2014], or vegetables [Kaur et al., 2022]. Over the last decades, various by-product flours originating from food processing industry have been used in pasta formulation. Besides, these by-products contain not only dietary fiber and antioxidants but also different nutrients, such as protein and minerals, which are useful for human health. Nevertheless, the use of high ratio of food by-products in the recipe of pasta may decrease its textural profile, cooking quality and sensory properties [Bianchi et al., 2021].

Cashew (Anacardium occidentale L.) trees are grown in tropical regions; among them Brazil, India, and Vietnam are countries with the largest export volume of cashew nuts in the world [Duarte et al., 2017]. The cashew apple or cashew fruit is the pseudo-fruit above the cashew nut. After separation of cashew nut, the fruit is used to produce some value-added products, such as jam, sauce, and cashew apple juice. The obtained juice can also be used as the main material to manufacture cashew apple cordial, syrup, jelly, vinegar, and fermented beverages [Preethi et al., 2021]. The production of cashew apple juice generates a by-product – cashew apple pomace, the predominant compounds of which are cellulose and hemicellulose. Polysaccharides of this by-product are treated with microbial carbohydrases to produce sugars which are subsequently used to obtain different products, such as bioethanol, enzymes, organic acids, and xylitol [Jeyavishnu et al., 2021]. Recently, cashew apple pomace has been reported to contain not only phenolic compounds with high antioxidant activity but also different nutrients, including valuable proteins and minerals and therefore this by-product was added to the formulation of cereal extrudates to enhance their antioxidant activity and functional properties [Preethi et al., 2021]. However, the use of cashew apple powder in pasta making has not been considered.

The purpose of this study was to evaluate the effects of cashew apple pomace ratios in pasta formulation on the proximate composition, antioxidant activity, physical properties, cooking properties, and consumer acceptability of the pasta.

MATERIALS AND METHODS

Materials

Ripe cashew apple (Anacardium occidentale L.) fruits without pestilence or damage were collected from a farm in Binh Phuoc province, Vietnam. After harvesting, the selected fruits were transported to Food Technology laboratory of Ho Chi Minh City University of Technology (Vietnam) and used for the preparation of cashew apple pomace powder within 24 h.

Durum wheat (Triticum durum) semolina was provided by Vietnam Flour Mills Co. (Ba Ria, Vung Tau province, Vietnam). Table salt was supplied by the Southern Salt Group Co. (Ho Chi Minh City, Vietnam).

Chemical reagents were purchased from Merck (Darmstadt, Germany) and they were of analytical grade. Enzyme preparations with α-amylase, glucoamylase, and protease activities were supplied by Novozymes (Bagsværd, Danmark) and used for analysis of dietary fiber.

Preparation of cashew apple pomace powder

Firstly, the nuts were manually removed; the fruits were washed with tap water, drained for 30 min, and squeezed for juice extraction. The obtained cashew apple pomace was cut into 3×2×1 cm pieces, which were subsequently blanched in 1% (w/v) sodium metabisulphite solution at 95°C for 10 min and drained for 10 min. The pomace was then dried at 55°C to less than 13 g/100 g moisture content, milled in a crusher, and sifted through a 70-mesh sieve. The cashew apple pomace powder (CAPP) was vacuum packed in polyethylene bags and stored at room temperature for experimentation.

Pasta making

A blend of durum wheat semolina and CAPP was used in the pasta recipe. There were five pasta samples in which the CAPP ratio was 0 (control), 5, 10, 15, and 20% of the blend weight.

The blend and table salt (0.5% on blend basis, w/w) were mixed in a stand mixer (Model HBD-805, Ukoeo, Zhuhai, China) with a paddle attachment for 2 min. To make a dough, distilled water at 42°C (47 g water/100 g flour) was added to the mixture and mixed at 120 rpm for 5 min. The dough was then kneaded using a dough hook at 120 rpm for 20 min before being fed to an extruder (Model HR2365/05, Philips Co., Shanghai, China). The die diameter was 1.6 mm and the extrusion pressure was 720 kgf/cm2. The obtained pasta strands were oven-dried at 50°C for 8 h to less than 13 g/100 g moisture content. The dried pasta was kept at room temperature for 24 h before analysis.

Proximate composition analysis

Protein content was measured by AOAC International 992.23 method with a nitrogen-to-protein conversion factor of 6.25 [AOAC, 2000]. Lipid content was determined by AOAC International 920.85 method with diethyl ether solvent [AOAC, 2000]. Total starch content was quantified by spectrophotometric method, using dinitrosalicylic acid as reagent [Nielsen, 2017]. Total, soluble, and insoluble dietary fiber contents were estimated by AOAC International 985.29, 991.42, 993.19 methods, respectively [AOAC, 2000]. The moisture content was determined by drying at 105°C in a moisture analyzer (Model IR35, A&D Co., Tokyo, Japan) [Nielsen, 2017].

Determination of total phenolic content and antioxidant capacity

For the extraction of phenolics from durum semolina, CAPP, and uncooked pasta, each ground sample (1 g) was mixed with 10 mL of a 60% (v/v) acetone solution and left at room temperature for 30 min. The mixture was then filtered through an ashless filter paper. The filtrate was collected, filled to 100 mL with 60% (v/v) acetone solution, stored at –4°C away from light, and used within 2 days. The obtained extracts were used for determination of total phenolic content as well as 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical scavenging activity and ferric reducing antioxidant power (FRAP).

Total phenolic content (TPC) was evaluated by spectrophotometric method, using Folin-Ciocalteu reagent; the analytical procedure was described by Biney & Beta [2014]. The results were shown as mg gallic acid equivalent per 100 g dry weight of sample (mg GAE/100 g dw).

The DPPH radical scavenging activity and FRAP were determined by spectrophotometric method following the procedures reported by Nguyen et al. [2020]. The results were expressed as μmol Trolox equivalent per 100 g dry weight of sample (μmol TE/100 g dw).

Water and oil holding capacity determination

The water holding capacity (WHC) was measured using the procedure described by Sangokunle et al. [2020] with some adjustments. About 1 g of the sample was soaked in 10 mL of distilled water and vortexed for 1 min. The mixture was left at room temperature for 2 h and then centrifuged at 1064×g (Certomat® BS-1, Sigma, Saint Louis, MO, USA) at room temperature for 10 min. The supernatant was removed while the sediment was weighed. The results were shown as g water/100 g dw.

The oil holding capacity (OHC) was quantified following the procedure described by Sangokunle et al. [2020] with some modifications. The sample (1 g) was soaked in 10 mL of soya oil and then vortexed for 1 min. The mixture was left at room temperature for 2 h and then centrifuged at 1064×g at room temperature for 10 min. The supernatant was decanted and the pellet was weighed. The results were expressed as g oil/100 g dw.

Cooking quality determination

The optimal cooking time (OCT), cooking loss, water absorption index (WAI), and swelling index (SI) were evaluated according to the procedure presented by Foschia et al. [2015] with minor modifications. The pasta sample (ca. 5 g) was cut into 5-cm strands and cooked in 50 mL of boiling distilled water. The OCT was recorded when white inner core of pasta just disappeared. At the end of cooking, the pasta strands were separated for draining for 4 min, and weighed (W2). The cooked and drained pasta strands were dried at 105°C to constant weight (W3). The cooking water was finally evaporated at 105°C to measure the total dry matter. The cooking loss was calculated as the percentage of the total dry matter of cooking water to the dry weight of raw pasta (W1).

The SI (%) and WAI (%) were calculated according to Equations (1) and (2), respectively.

Textural properties analysis

The textural properties of cooked pasta were determined with a texture analyzer (TA-XT Plus C, Stable Micro System, Godalming, United Kingdom) equipped with a Windows version of Exponent Connect Lite 7.0 software (Texture Technologies Co., Hamilton, MA, USA). A 70% axial compression of cooked pasta strand was done using a 40-mm diameter acrylic probe. The compression speed was 1 mm/s. After 1 s of the first compression, the second compression cycle was performed. The hardness, adhesiveness, springiness, cohesiveness, gumminess, and chewiness of cooked pasta samples were obtained from the force-time curve.

In the tensile strength test, cooked pasta strand was wound around parallel friction rollers two times (Pasta Tensile Rig, Stable Micro Systems). The extension speed was 1 mm/s. The tensile strength (TS, g/mm2) and elongation rate (ER, %) were determined according Equations (3) and (4), respectively.

where: F is the force at the break point (g), and S is the cross-sectional area of the cooked pasta strand (mm2). where: D is the distance at the break point (mm), and D0 is the initial distance (mm).Instrumental color measurement

Color of uncooked and ground pasta samples was determined using a Minolta chroma meter CM-3700A (Konica Minolta, Tokyo, Japan). The results were shown as L* (lightness), a* (redness), and b* (yellowness) values. Color data were the mean of three replicate readings. The total color difference (ΔE) was determined as follows:

where: L0*, a0* and b0*are the color values of the control pasta sample; and L*, a* and b* are the color values of the CAPP added pasta sample.Overall acceptability evaluation

Pasta samples were cooked for 1 min longer than the established optimal cooking time before being evaluated by 60 young adults aged from 18 to 25 to assess the overall acceptability, using a 9-point hedonic scale (from 1 – extremely dislike to 9 – extremely like). The evaluators were recruited from the students at Ho Chi Minh City University of Technology (Vietnam). The evaluators were provided with water to cleanse their palate before testing and between pasta samples. Five pasta samples were served in random order. The semi-consumer evaluation was conducted in a laboratory at ambient temperature.

Statistical analysis

All experiments were done in triplicate. The results were expressed as mean ± standard deviation. One-way analysis of variance (ANOVA), correlation coefficients between variables and Duncan’s multiple range test with significance level of p<0.05 were done using Statgraphics Centurion 18.1.12 software (Statgraphics Technologies, Inc., The Plains, VA, USA).

RESULTS AND DISCUSSION

Proximate composition, antioxidant activity, and physical properties of cashew apple pomace powder and durum semolina used for pasta making

The proximate composition, antioxidant activity, and physical properties of CAPP and durum semolina used in the study were shown in Table 1. The CAPP contained more lipid and ash but had lower protein and starch content compared to the durum semolina. The total dietary fiber (TDF), insoluble dietary fiber (IDF), and soluble dietary fiber (SDF) content of CAPP was 20.1, 25.2, and 7.7 times, respectively, higher than that of durum semolina. The proximate composition of CAPP in this research was different to that reported by Duarte et al. [2017] or Preethi et al. [2021] due to the difference in cultivars of cashew apple, growing conditions of plant as well as cashew apple juice processing conditions.

Table 1

Proximate composition, antioxidant activity, and physical properties of cashew apple pomace powder and durum wheat semolina used for pasta making.

[i] Data are shown as mean ± standard deviation (n=3). Values with different letters in the same row are significantly different (p<0.05). dw, dry weight; TDF, total dietary fiber; IDF, insoluble dietary fiber; SDF, soluble dietary fiber; GAE, gallic acid equivalent; DPPH radical, 2,2-diphenyl-1-picrylhydrazyl radical; TE, Trolox equivalent.

The CAPP was rich in phenolics, the total content of which was about 50 times higher than that of durum semolina (Table 1). As a result, the DPPH radical scavenging activity, and ferric reducing antioxidant power of CAPP were 140 and 229 times, respectively, higher than those of durum semolina. Different phenolic compounds with high antioxidant activity were identified in cashew apple pomace, such as gallic acid, myricetin, and quercetin [Silveira et al., 2021]. It can be suggested that the addition of CAPP to pasta recipe would improve dietary fiber content and antioxidant activity of the product.

Results in Table 1 also reveal that the CAPP was darker (lower L* value) than the durum semolina. This can be explained by Maillard reactions between the residual reducing sugars and amino acids/proteins in cashew apple pomace (data not shown) during the drying process. In addition, the positive a* and b* values of CAPP color were recorded probably due to its red and yellow pigments, respectively. It is reported that the peel and pulp of ripen cashew apple contains carotenoids which exhibit red, yellow and other colors [Schweiggert et al., 2016].

The WHC of CAPP was 2.8 times higher than that of semolina while their OHC was similar (values were not significantly different, p<0.05) (Table 1). The cashew apple fiber mainly consists of cellulose, hemicellulose, and lignin [Jeyavishnu et al., 2021]. According to Chami Khazraji & Robert [2013], water molecules could rapidly interact with cellulose in both interfibrillar spaces and amorphous regions. Previous studies showed that red raspberry fruit pomace [Gouw et al., 2017] and apple pomace [Wang et al., 2019] with high cellulose content also had high WHC.

Effects of ratios of cashew apple pomace powder on proximate composition of pasta

The proximate composition of pasta fortified with CAPP is presented in Table 2. When the CAPP level in the pasta formulation increased from 0 to 20%, the lipid and ash content of the product increased by 2.1 times and 1.9 times, respectively, while its protein and starch content decreased by 48% and 15%, respectively. This is due to the increased level of CAPP in the pasta recipe and the high lipid and ash content as well as the low starch and protein content of CAPP (Table 1). At 5% CAPP level, the TDF, IDF and SDF content of the obtained pasta enhanced by 2.1, 2.7 and 1.3 times, respectively, compared to that of the control pasta (Table 2). The greater the CAPP level in the pasta recipe was, the higher was the dietary fiber content of the product. Similar results were reported when cucumber pomace powder [Saad et al., 2021] and grape pomace powder [Balli et al., 2021] were added to the pasta formulation. It should be noted that pasta with 5% CAPP or higher level can be claimed as high-dietary fiber pasta following the labeling guidelines of the European Union, in which food with TDF content higher than 6 g/100 g dw is considered a product high in fiber [Tolve et al., 2020]. According to Oba-Yamamoto et al. [2022], low-starch and high-fiber pasta is proven to help control blood glucose levels and to prevent and/ or take part in the treatment of type 2 diabetes.

Table 2

Proximate composition of pasta with different cashew apple pomace powder (CAPP) levels.

Increase in CAPP level in the pasta formulation from 0% to 20% enhanced the IDF:SDF ratio from 1.3:1 to 4.0:1 (w/w). The pasta samples with 5% and 10% CAPP had IDF:SDF ratio close to the dietetic recommendations, i.e., 3:1, w/w [Bader Ul Ain et al., 2018]. The previous studies revealed that the IDF:SDF ratio of pasta with 10% wheat bran, tomato peel or coconut residue was 4.0:1 [Nguyen et al., 2020], 2.2:1 [Padalino et al., 2017] or 1.5:1 (w/w) [Sykut-Domańska et al., 2020], respectively. Therefore, the pasta supplemented with 10% CAPP had a fairly balanced IDF:SDF ratio as compared to that fortified with other dietary fiber sources.

Effects of ratios of cashew apple pomace powder on the total phenolic content and antioxidant capacity of pasta

Figure 1 presents the TPC and antioxidant capacity of pasta with different CAPP levels. Increase in CAPP ratio in the pasta recipe from 0 to 20% greatly improved TPC of the product. The TPC of pasta fortified with 10% CAPP was 7.6 times higher than that of the control pasta. It should be noted that at 10% fiber material level, the CAPP-incorporated pasta had much more total phenolics (794 mg GAE/100 g dw) than earlier analyzed grape pomace-supplemented pasta (257 mg GAE/100 g dw) [Tolve et al., 2020], and olive pomace added pasta (228 mg GAE/100 g dw) [Simonato et al., 2019].

Figure 1

Total phenolic content (A), DPPH radical scavenging activity (B) and ferric reducing antioxidant power (C) of the pasta supplemented with different ratios of cashew apple pomace powder. GAE, gallic acid equivalent; dw, dry weight; TE, Trolox equivalent. Data are shown as mean ± standard deviation (n=3). Bars with different letters show significantly different values (p<0.05).

The pasta with high CAPP level had improved antioxidant capacity. The DPPH radical scavenging activity and FRAP of pasta with 20% CAPP level increased by 18.2 times and 28.7 times, respectively, compared to those of the control pasta (Figure 1B and Figure 1C).

Close significant (p<0.05) correlations were observed for TPC and antioxidant capacity of the CAPP pasta samples. The correlation coefficients between TPC and DPPH radical scavenging activity as well as between TPC and FRAP were 0.955 and 0.980, respectively.

Effects of ratios of cashew apple pomace powder on cooking quality of pasta

The cooking quality of pasta with different CAPP levels is shown in Table 3. Increase in CAPP ratio in the pasta formulation from 0 to 20% decreased optimal cooking time of the product from 13.5 to 6.4 min. Reduction in optimal cooking time was also reported by Nguyen et al. [2020] when wheat bran was added to pasta recipe. According to these authors, the decrease in gluten content and the presence of fiber in pasta result in more channels for water diffusion from cooking water into pasta; the optimal cooking time of high fiber pasta is therefore reduced.

Table 3

Cooking quality of pasta with different cashew apple pomace powder (CAPP) levels.

The cooking loss of pasta samples with 5–20% CAPP was 11–65% greater than that of the control (Table 3) mainly due to their decreased gluten content. As a consequence, the gluten system was weakened and the diffusion of starch and other components from the pasta into the cooking water was enhanced [Chusak et al., 2020, Nguyen et al., 2020]. High cooking loss was also recorded for pasta samples fortified with gac fruit [Chusak et al., 2020] or berry powder [Bustos et al., 2019].

Water absorption index presents the amount of water absorbed into the product during the cooking process while swelling index shows the change in the volume of cooked pasta compared to uncooked one [Chusak et al., 2020]. Results provided in Table 3 reveal that the increase in CAPP ratio in the pasta formulation gradually reduced both WAI and SI. The water absorption index and swelling index of pasta with 20% CAPP dropped by 45% and 40%, respectively, compared to those of the durum semolina pasta. Similar trend has recently been observed by Chusak et al. [2020] when durum semolina was partially replaced by ripe gac fruit powder in the pasta recipe. The increased fiber content disrupted the starch-gluten network, allowing starch molecules to leak more into cooking water [Aravind et al., 2012]. At the same time, dietary fiber has greater hydration dynamic than starch; the water is held more loosely by fiber than by starch [Wang et al., 2020], leading to the decreased swelling index of the high-fiber pasta samples.

Effects of ratios of cashew apple pomace powder on physical properties of pasta

Textural properties of pasta samples with different CAPP ratios are presented in Table 4. When the CAPP ratio increased from 0 to 20%, the hardness of pasta rose by 46%. That can be explained by high water holding capacity of fiber in the pasta sample, leading to the prevention of water absorption and swelling of starch granules; this phenomenon caused the decrease in swelling index and made the cooked pasta become harder [Rakhesh et al., 2015]. The increase in hardness of pasta was also recorded when tomato pomace powder [Padalino et al., 2017] or soy okara powder were added to the product recipe [Kamble et al., 2019].

Table 4

Textural properties and instrumental color parameters of pasta with different cashew apple pomace powder (CAPP) levels.

Adhesiveness is the force required to remove the probe from the pasta sample. All pasta samples supplemented with CAPP had greater adhesiveness than the control pasta (Table 4). Increase in adhesiveness was previously reported when the ratio of tomato pomace powder added to the pasta recipe was 15% [Padalino et al., 2017]. The presence of fibers in pasta disrupted the continuity of its structure [Chusak et al., 2020]. According to Bouasla et al. [2017], the change in adhesiveness is related to the fiber content and the dissolution of components such as starch, protein, soluble fiber in the cooking water. These components may form sticky layers on the surface of pasta strands [Rakhesh et al., 2015].

Springiness represents the ability of pasta to recover its original shape after being subjected to an external force. At 20% CAPP ratio, the springiness of pasta decreased by 16% in comparison with that of the control (Table 4). Reduction in springiness was previously observed when apple pomace was added to pasta formulation [Xu et al., 2020]. Bustos et al. [2011] explained that the decrease in springiness was related to the weak development of the proteinstarch matrix due to the distribution of fiber in the pasta dough.

Cohesiveness measures the ability of pasta to withstand external forces before breaking, while gumminess is the force required to crush the pasta, and chewiness is the total force required to chew and swallow the product. The cohesiveness, gumminess, and chewiness of pasta with 20% CAPP decreased by 25%, 14%, and 35%, respectively in comparison with those of the control (Table 4). Decrease in cohesiveness and chewiness were also recorded for pasta samples supplemented with cucumber pomace [Saad et al., 2021]. The presence of insoluble fiber in the product reduces the swelling of starch granules because of water competition, leading to negative change in textural properties [Saad et al., 2021]. On the other hand, the disruption of the gluten network can also be a reason for the pasta to be broken more easily under external forces.

Among the textural properties of CAPP pasta, a close correlation was observed between the hardness as well as adhesiveness with the CAPP ratio in the pasta recipe. The CAPP level significantly (p<0.05), positively correlated with the hardness and adhesiveness and their correlation coefficients were 0.992 and 0.990, respectively. Similar correlation was reported when tomato pomace powder was supplemented to the pasta formulation [Padalino et al., 2017].

A tensile strength test is performed to clarify how much force is required to break pasta strands when they are pulled apart. Increase in CAPP ratio in the pasta recipe enhanced the tensile strength but decreased the elongation rate of pasta (Table 4). Shiau et al. [2020] also reported an increased tension strength as well as a reduced elongation rate of wheat noodles fortified with pitaya peel powder. According to the authors, the rigidity of fiber and the decrease in free water in the cooked pasta samples could cause the rise of tensile strength, while the decrease in elongation rate might be due to the weak gluten network of the high-fiber pasta.

Our study showed that the increased CAPP ratio in the pasta formulation negatively affected both textural and cooking properties of the product. Future studies on the interaction of CAPP fiber and protein-starch matrix of the blend dough are needed to clarify the effects of fiber on textural and cooking properties of high-fiber pasta.

The addition of CAPP to pasta recipe slightly enhanced darkness of the product since the L* value of CAPP was lower than that of durum semolina (Table 4). Similar results were reported when fruit pomace such as apple pomace [Xu et al., 2020] or grape pomace [Tolve et al., 2020] was added to the pasta formulation. The redness (positive a* value) and yellowness (positive b* value) were observed for all pasta samples and their values varied in narrow ranges. Higher levels of CAPP caused higher ΔE value, which proved a greater difference in color between the CAPP added pasta and the control pasta.

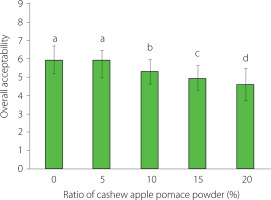

Effects of ratios of cashew apple pomace powder on overall acceptability of pasta

The overall acceptability of all cooked pasta samples is shown in Figure 2. Pasta with 5% CAPP had a similar score to the control while higher level of CAPP led to the decreased overall acceptability. The decrease in sensory score was also recorded when adding legume flour [Wójtowicz & Mościcki, 2014] or partiallydeoiled chia flour to the pasta recipe [Aranibar et al., 2018]. It can be explained by the negative change in textural profile of cooked pasta. Texture is the key property for the evaluation of pasta quality [Poonsri et al., 2019]. The increase in hardness may have strong effects on sensory properties of CAPP pasta since the customers did not favor pasta with high hardness [Prerana & Anupama, 2020]. Furthermore, the color of pasta is also a crucial property and is the first to affect the consumer acceptability [Sykut-Domańska et al., 2020]. The pasta samples with high CAPP levels had a distinctly darker color compared to the control with light yellow color. Pasta sample with 10% CAPP had an average liking score of 5.3, which could be considered acceptable.

CONCLUSIONS

Use of CAPP in the pasta recipe significantly increased the dietary fiber and TPC content as well as the antioxidant capacity of the final product. Nevertheless, a high ratio of CAPP in the pasta formulation reduced its cooking quality, textural properties, and overall acceptability. The pasta with CAPP addition level of 10% was considered high-fiber food with acceptable sensory quality. The interaction of CAPP fiber and protein-starch matrix of the blend dough needs to be investigated in the future to clarify the effects of fiber on textural properties and cooking quality of high-fiber pasta samples. Based on the present study results, CAPP may be found a potential ingredient for the development of different food products with high fiber and antioxidant content.